Preparation method of microstructure surface with alternate hydrophilic-hydrophobic distribution

A microstructure, hydrophilic and hydrophobic technology, applied in coatings and other directions, can solve problems affecting the ecological environment and achieve the effect of improving broad-spectrum antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

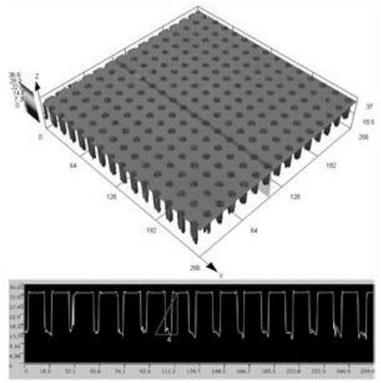

[0020] The process of the method for preparing the surface of the hydrophilic-hydrophobic interactive distribution microstructure involved in this embodiment is as follows: first, the photomask with the set pattern is etched by electron beams, and the photomask is covered on the surface of the single crystal silicon; A set pattern with a depth of 20 microns is etched on the silicon surface, and the etched single crystal silicon surface is used as a negative mold, such as figure 1 As shown, the hydrophobic silicone microstructure surface was obtained by turning over the mold, and then, under vacuum conditions, the hydrophobic silicone microstructure surface was subjected to plasma activation treatment with a voltage of 1.0V and a current of 0.4A for 10 minutes, followed by , drip hydrochloric acid hydrogen peroxide solution on the surface of the hydrophobic silicone microstructure, and cover a layer of dimethyl silicone oil, after 15 minutes, rinse the surface of the hydrophobic...

Embodiment 2

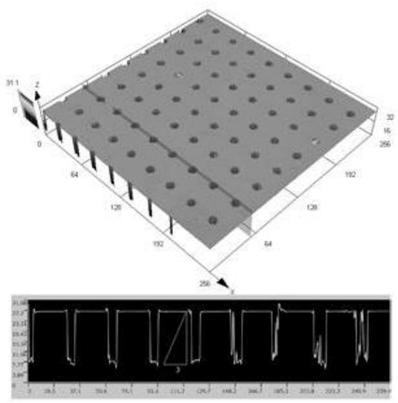

[0022] The process of the method for preparing the surface of the hydrophilic-hydrophobic interactive distribution microstructure involved in this embodiment is as follows: first, the photomask with the set pattern is etched by electron beams, and the photomask is covered on the surface of the single crystal silicon; A set pattern with a depth of 20 microns is etched on the silicon surface, and the etched single crystal silicon surface is used as a negative mold, such as image 3 As shown, the hydrophobic silicone microstructure surface was obtained by turning over the mold, and then, under vacuum conditions, the hydrophobic silicone microstructure surface was subjected to plasma activation treatment with a voltage of 3.0V and a current of 2.0A for 5 minutes, followed by , drop hydrochloric acid hydrogen peroxide solution on the surface of the hydrophobic silicone microstructure, and cover a layer of liquid paraffin, after 5 minutes, rinse the hydrophobic silicone microstructur...

Embodiment 3

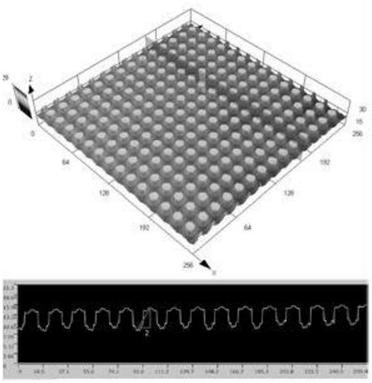

[0024] The process of the method for preparing the surface of the hydrophilic-hydrophobic interactive distribution microstructure involved in this embodiment is as follows: first, the photomask with the set pattern is etched by electron beams, and the photomask is covered on the surface of the single crystal silicon; Etch a set pattern with a depth of 10 microns on the silicon surface, use the etched single crystal silicon surface as a negative mold, and obtain a hydrophobic organic silicon microstructure surface by turning over the mold, and then, under vacuum conditions, with a voltage of 2.0V and a current of 1.0A to perform plasma activation treatment on the surface of the hydrophobic organosilicon microstructure for 8 minutes. Next, drop hydrochloric acid and hydrogen peroxide solution on the surface of the hydrophobic organosilicon microstructure, and cover a layer of two layers with a volume ratio of 1:1. A mixed liquid of methyl silicone oil and methyl phenyl silicone o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com