Castable for aluminum melting furnace lining and preparation method and using method of castable

An aluminum melting furnace and castable technology, applied in the field of refractory development, can solve the problems of low service life, high production cost, easy loosening, etc., and achieve the effects of improving service life, stable thermal shock performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing the castable for the furnace lining of the aluminum melting furnace, comprising the following steps:

[0031] Weigh the raw materials according to the weight ratio, add them to the mixer according to the order of the particle size of the raw materials from large to small, and the stirring time is more than 5min / filling to obtain the castable for the furnace lining of the aluminum melting furnace.

[0032] The present invention also provides a method for using the castable for the lining of the aluminum melting furnace, comprising the following steps:

[0033] a. Remove the bricks of the aluminum melting furnace as a whole, clean up the sundries on the inner wall of the steel mold cover, drill out the air holes with a horizontal and vertical spacing of 40cm and a diameter of 8cm evenly distributed on the steel mold cover of the aluminum melting furnace, and then drill the air holes on the inner wall of the steel m...

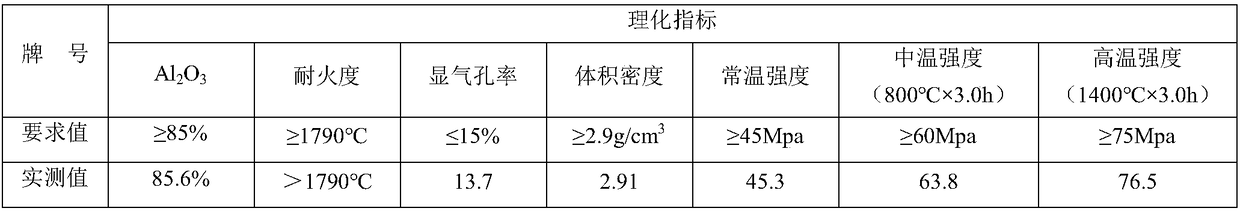

Embodiment 1

[0037] Embodiment 1 Preparation of aluminum melting furnace lining castable of the present invention, laboratory test and physical and chemical performance detection

[0038] According to the theoretical formula design of aluminum melting furnace lining castables, small sample tests and physical and chemical performance tests were carried out in the laboratory. The test design castable formula consists of: fused brown corundum 68.0%, bauxite powder 20.0%, α-alumina Micropowder 4.0%, calcium aluminate cement 3.0%, super silica micropowder 4.0%, stainless steel fiber 1.5%, superplasticizer 0.25%, explosion-proof fiber 0.05%.

[0039] The specific operation steps are:

[0040] a. Preparation of castable

[0041] After weighing the raw materials, add them to the mixer in order of particle size from large to small, and the stirring time is ≥5min / fill to obtain castables for aluminum melting furnace lining; and test the chemical composition of the castables.

[0042] b. Mix the pr...

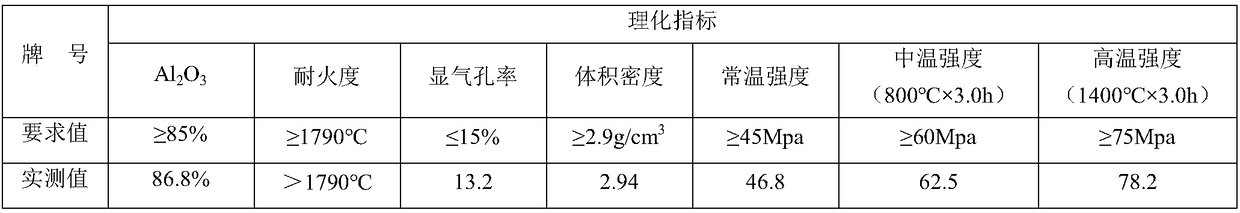

Embodiment 2

[0047]Example 2 Preparation of aluminum melting furnace lining castable of the present invention, laboratory test and physical and chemical performance detection

[0048] According to the theoretical formula design of aluminum melting furnace lining castables, small sample tests and physical and chemical performance tests were carried out in the laboratory. The test design castable formula consists of: fused brown corundum 70.0%, bauxite powder 18.0%, α-alumina Micro powder 6.0%, calcium aluminate cement 3.0%, super silica micro powder 3.0%, stainless steel fiber 1.0%, superplasticizer 0.3%, explosion-proof fiber 0.03%.

[0049] The specific operation steps are:

[0050] a. Preparation of castable

[0051] After weighing the raw materials, add them to the mixer in order of particle size from large to small, and the stirring time is ≥5min / fill to obtain castables for aluminum melting furnace lining; and test the chemical composition of the castables.

[0052] b. Mix the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com