Composite heavy anti-corrosion structure for thermal power plant titanium plate chimney and construction technology

A technology for thermal power plants and construction processes, applied in anti-corrosion coatings, coatings, buildings, etc., can solve problems such as difficult to achieve uniformity of construction, unstable construction quality, and tiny cracks, ensuring long-term stability and isolating substrates. The effect of contact with the outside world and good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

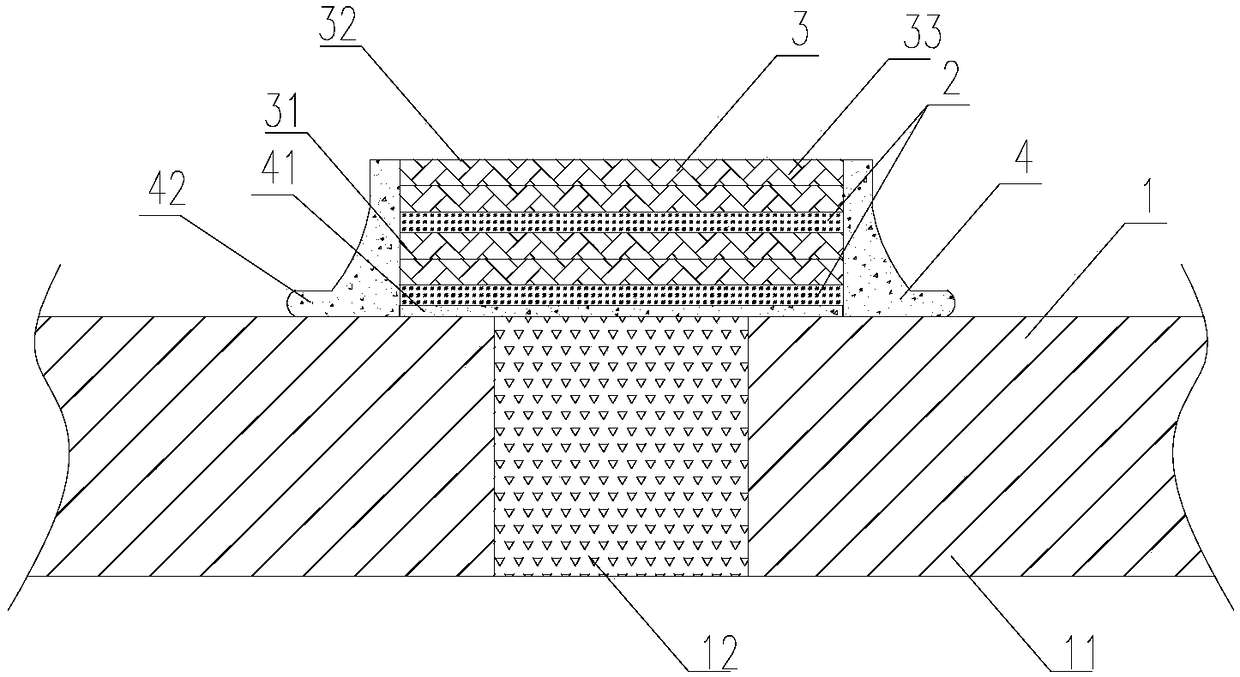

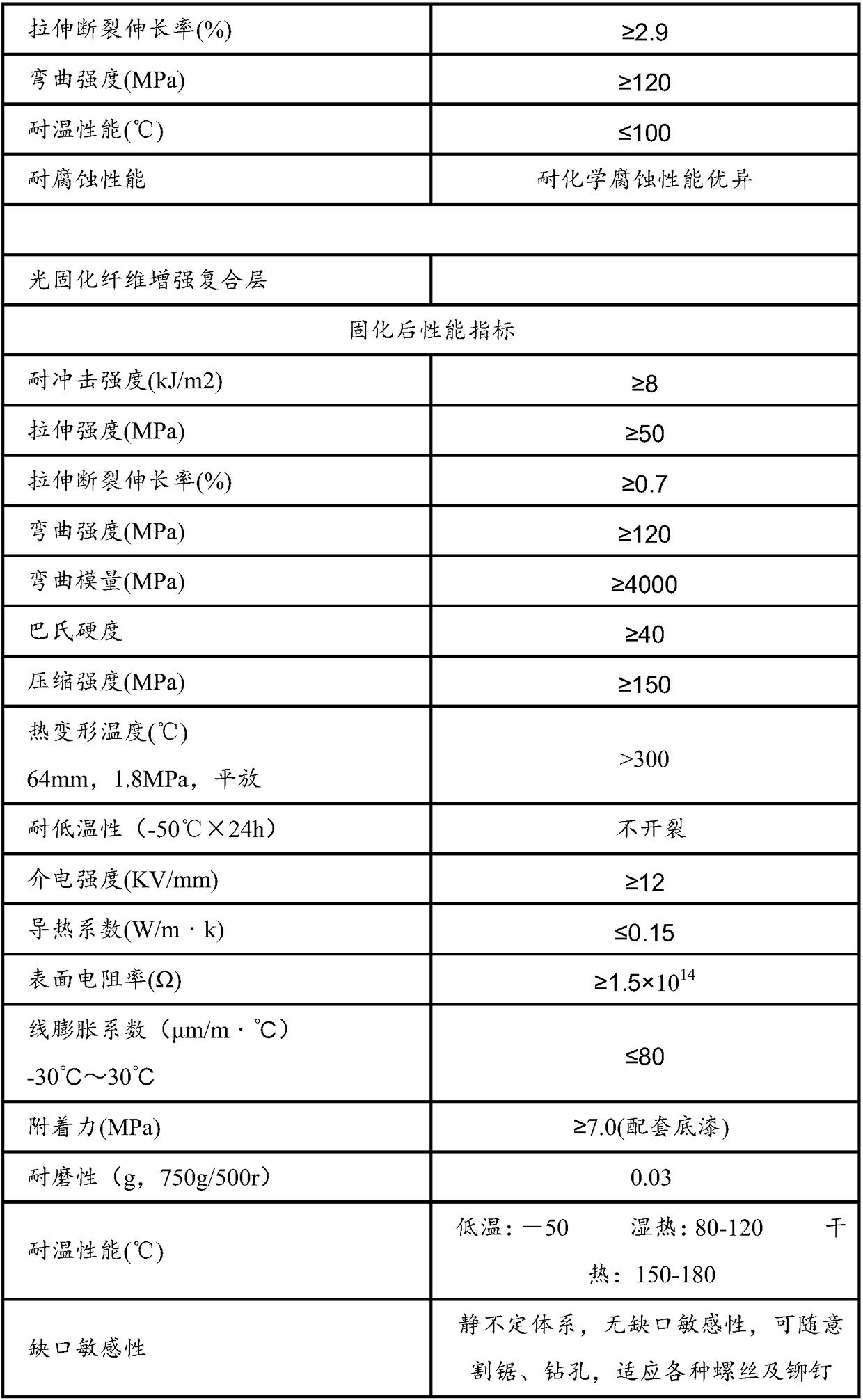

[0033] refer to figure 1 As shown, the composite heavy-duty anti-corrosion structure for the titanium plate chimney of the thermal power plant is set on the titanium plate chimney body 1, the nanocomposite emulsion titanium plate base coating 2, at least one layer of light-cured fiber reinforced composite layer 3 and the sealing coating 4;

[0034] The titanium plate chimney body 1 is formed by welding a plurality of titanium plates 11, the nanocomposite emulsion titanium plate base coating 2 and at least one layer of light-cured fiber reinforced composite layer 3 are sequentially arranged at the weld seams of the multiple titanium plates for Close the weld seam 12;

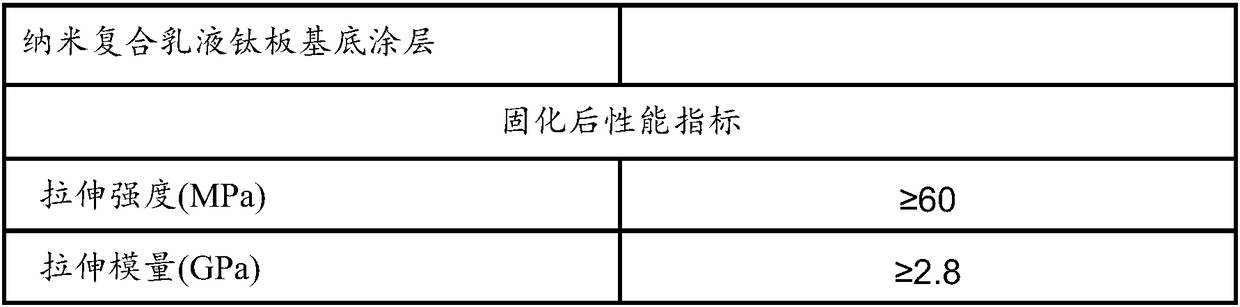

[0035] Nano-composite emulsion titanium plate base coating 2, use the nano-composite emulsion titanium plate base paint to brush, and extend at least 150mm along both sides of the weld. This kind of nano-composite emulsion metal base coat is composed of the following raw materials by weight: modified vinyl 38% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com