Cast and formed blade guiding frame and casting forming method thereof

A casting molding and guide frame technology, which is applied to casting molding equipment, casting molds, and casting mold components, can solve the problems of low utilization rate of blank materials, large blank machining allowance, and long processing cycle, so as to save raw materials and simplify The effect of small production process and machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

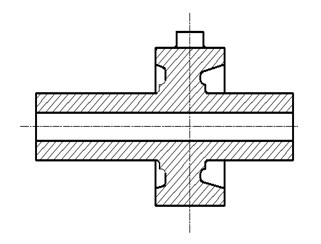

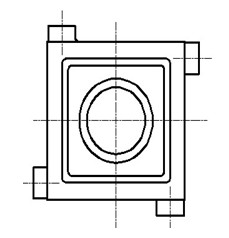

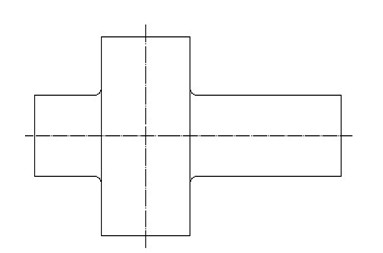

Image

Examples

Embodiment 1

[0017] Example 1: A cast-molded blade guide frame, chemical composition (mass fraction): C: 0.38-0.44%, Si: 0.20-0.35%, Mn: 0.60-0.90%, S:≤0.030%, P: ≤0.030%, Cr: 0.90~1.20%, Mo: 0.15~0.30%, V: 0.05~0.08%, Ti: 0.005~0.01%.

Embodiment 2

[0018] Example 2: A casting method for the blade guide frame, (1) by adding subsidies in the process design, the center of the hot joint deviates from the casting body; Cold iron chilling, in order to further increase heat dissipation and improve the chilling effect, the surface of the mold cavity that is in direct contact with the molten steel uses chromite sand with a chilling capacity 4 times that of ordinary silica sand, which reduces the geometric thermal section by about 15%. Adding an air outlet pipe in the end area is not only beneficial to the removal of gas in the cavity, but also helps the heat dissipation of the cavity by the part of the heat taken away by the gas discharge; (3) The composition of the material is optimized by adding V and Ti microalloying elements , increase the low temperature brittle transition temperature, improve the plasticity and toughness of the material; a. V is an excellent deoxidizer for steel. Adding V to steel can refine the structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com