Production method of vanadium-titanium iron powder

A production method, vanadium-titanium-iron technology, applied in the field of powder metallurgy, can solve problems such as complex production process, achieve high purity, realize waste utilization, and achieve good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

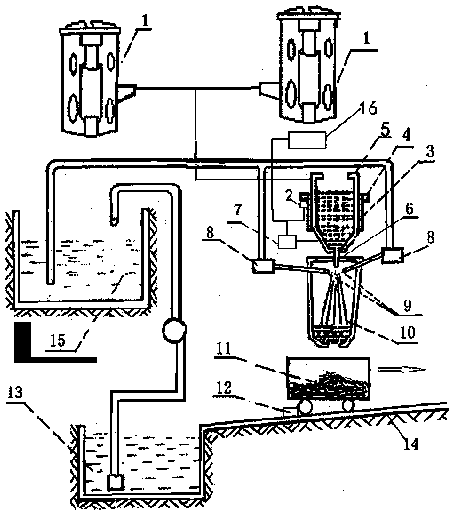

Image

Examples

Embodiment 1

[0028] A method for producing vanadium-titanium iron powder, comprising the steps of:

[0029](1) Put steel scrap into intermediate frequency electric furnace for smelting, and then adjust the steel with vanadium-titanium alloy, so that the chemical composition of vanadium-titanium molten steel smelted in intermediate frequency electric furnace is: 0.1% V; 0.5% Ti; 0.4% C; 0.4% Si; 0.4% Mn; 0.005%P; 0.005%S;

[0030] 2) The molten vanadium-titanium steel smelted in the intermediate frequency electric furnace is continuously injected into the atomizing feeding tank, and the composition is continuously adjusted. The composition is controlled as follows: 0.1% V; 0.06% Ti; 0.15% C; Si0.3%; Mn0.3%; P0 .004%; 0.001% S; and control the temperature of the vanadium-titanium molten steel in the atomization feeding tank to be 1680°C;

[0031] (3) The vanadium-titanium molten steel whose composition and temperature have been adjusted in step (2) flows down from the leak hole of the atomi...

Embodiment 2

[0034] A method for producing vanadium-titanium iron powder, comprising the steps of:

[0035] (1) Add steel scrap to intermediate frequency electric furnace for smelting, and then adjust steel with vanadium-titanium alloy, so that the chemical composition of vanadium-titanium molten steel smelted in intermediate frequency electric furnace is: 0.5% V; 0.6% Ti; 0.3% C; 0.3% Si; 0.3% Mn; 0.004%P; 0.004%S;

[0036] (2) Continuously inject molten vanadium-titanium steel smelted in an intermediate frequency electric furnace into the atomizing feeding tank, and continuously adjust the composition. The composition is controlled as follows: 0.1% V; 0.06% Ti; 0.25% C; 0.2% Si; 0.2% Mn; 0.003% P; 0.0005% S; and control the temperature of the vanadium-titanium molten steel in the atomization feeding tank to be 1650°C;

[0037] (3) The vanadium-titanium molten steel whose composition and temperature have been adjusted in step (2) flows down from the leak hole of the atomization feeding t...

Embodiment 3

[0040] A method for producing vanadium-titanium iron powder, comprising the steps of:

[0041] (1) Put steel scrap into intermediate frequency electric furnace for smelting, and then adjust steel with vanadium-titanium alloy, so that the chemical composition of vanadium-titanium molten steel smelted in intermediate frequency electric furnace is: 0.3% V; 0.3% Ti; 0.2% C; 0.2% Si; 0.2% Mn; 0.002%P; 0.002%S;

[0042] 2) The vanadium-titanium molten steel smelted in the intermediate frequency electric furnace is continuously injected into the atomizing feeding tank, and the composition is continuously adjusted and controlled as follows: 0.1%V; 0.06%Ti; 0.3%C; 0.1%Si≤; 0.1%Mn; 0.001%P ; 0.0008% S; and control the temperature of the vanadium-titanium molten steel in the atomization feeding tank to be 1680°C;

[0043] (3) The vanadium-titanium molten steel whose composition and temperature have been adjusted in step (2) flows down from the leak hole of the atomization feeding tank i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com