Auxiliary support structure and application method thereof for laser selective forming of suspended plane

A technology of laser selective melting and auxiliary support, which is applied in the field of additive manufacturing, can solve the problems of affecting the dimensional accuracy of formed products, SLM forming failure, and the reduction of the ability of support to resist shearing, so as to reduce the forming time and the amount of raw materials used, Ensure the support strength and ensure the effect of smooth forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

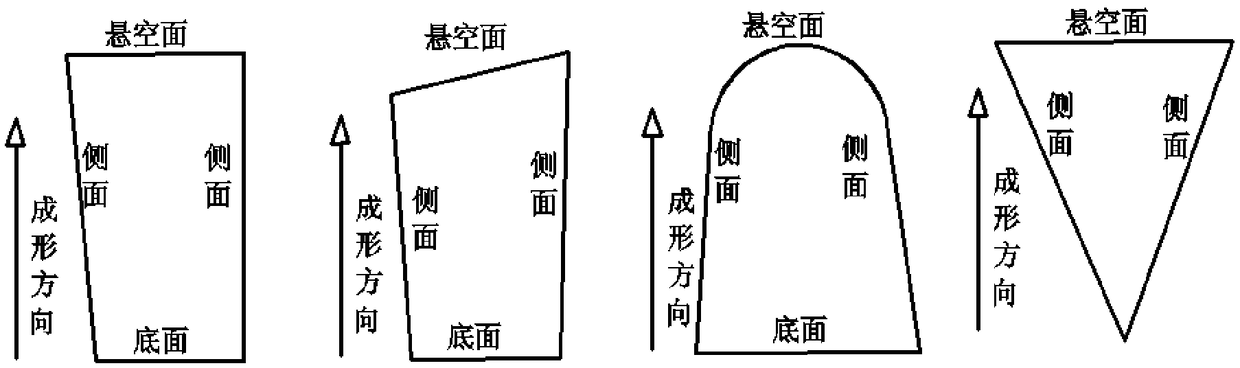

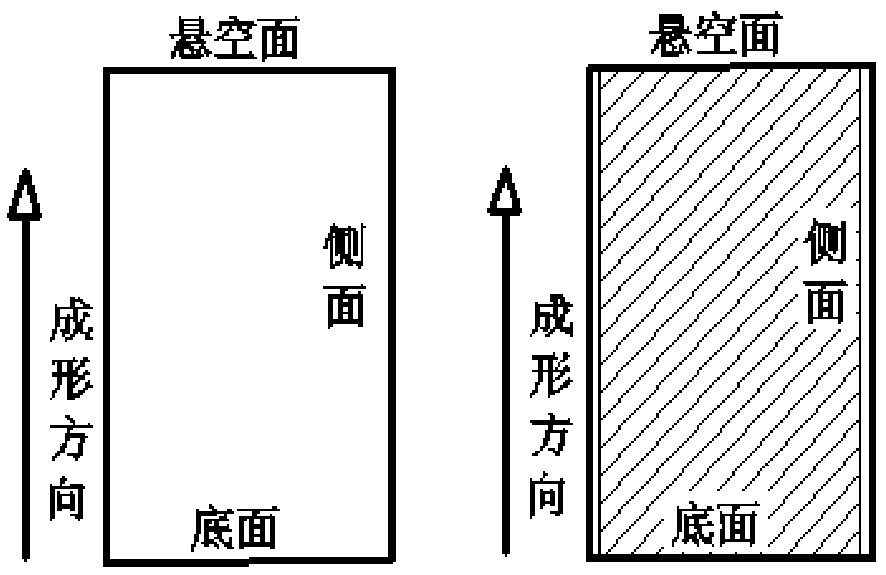

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

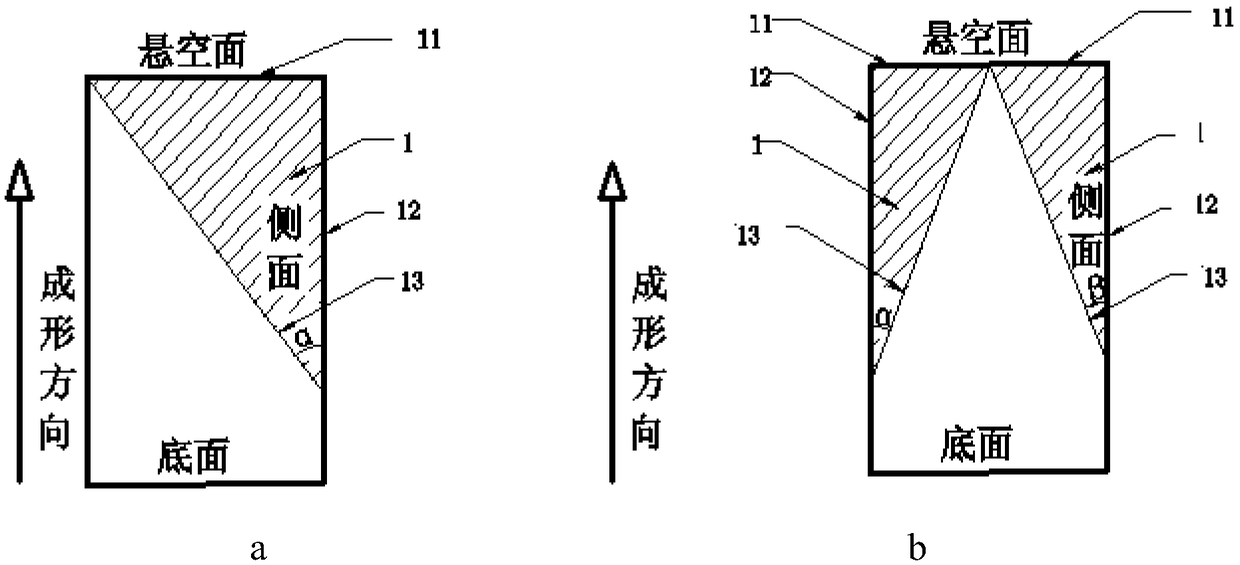

[0042] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0043] See image 3 The embodiment of the present invention provides an auxiliary support structure for laser selective melting and forming, which includes at least one support block 1. The support block 1 is provided with a first support surface 11, a second support surface 12, and a suspended plane 13. The first supporting surface 11 is used to connect with the suspended surface of the product to support the suspended surface, the second supporting surface 12 is used to connect with the inner surface of the product, and the surface of the suspended surface 13 is connected to the suspended surface of the product. The first supporting surface 11 and the second supporting surface 12 intersect.

[0044] Specifically, the auxiliary support structure provided by the embodiment of the present invention is formed by laser selectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com