Wet-process molded battery diaphragm with controllable pore diameter and preparation method thereof

A battery diaphragm, wet forming technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of easy shrinkage of micropores, failure to guarantee battery safety performance, high diaphragm thickness, etc., to improve discharge platform and low temperature performance , The assembly process is simple and easy, and the effect of ensuring safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

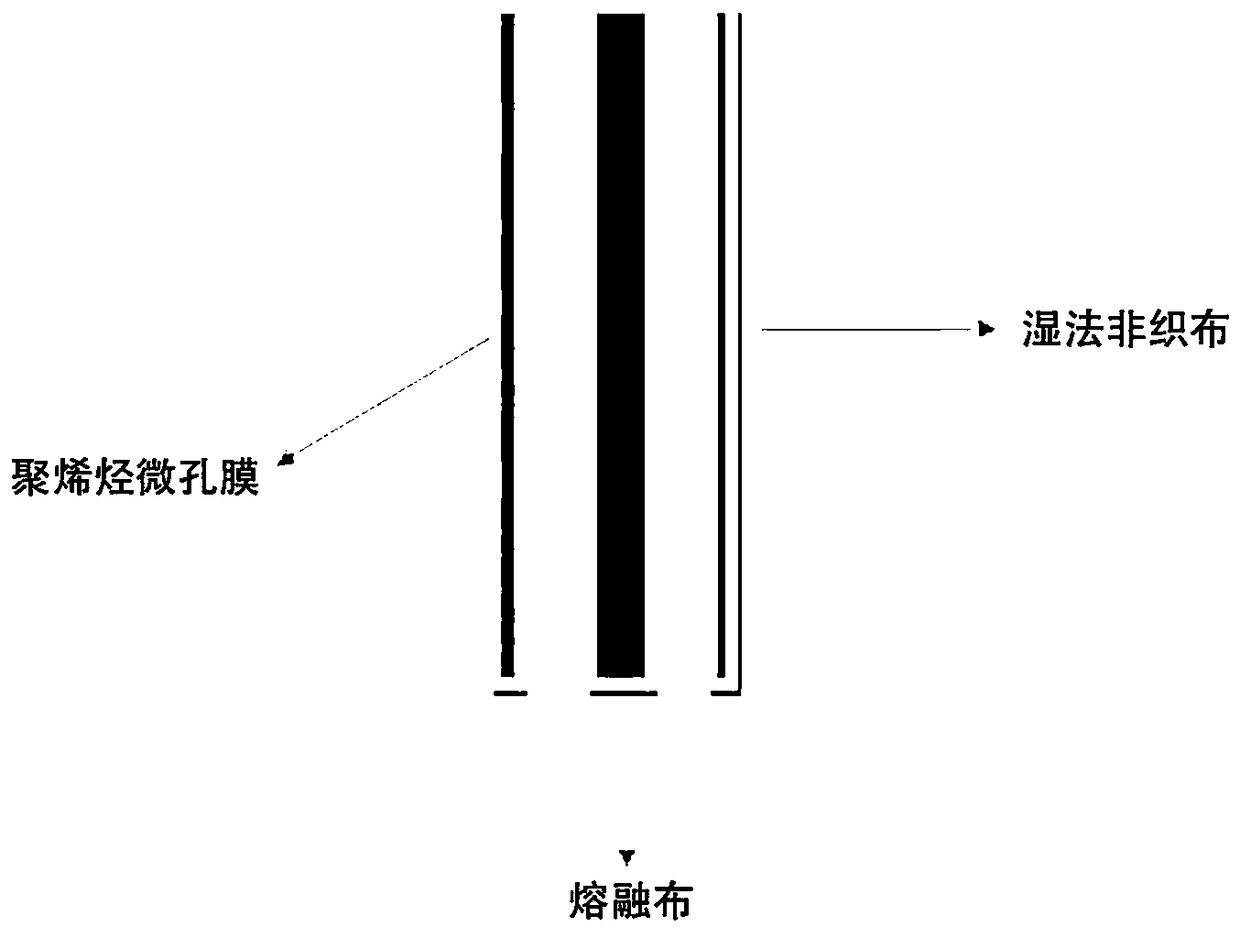

[0031] A wet-formed battery separator with controllable pore size. The battery separator is based on a three-layer composite film composed of polyolefin microporous film, melted cloth, and wet-laid non-woven fabric containing polyethylene short fibers. A composite membrane formed by radiation grafting of carboxyl and / or sulfonic acid functional groups.

[0032] Wherein, the polyolefin microporous membrane is a polyethylene microporous membrane, the porosity of the polyolefin microporous membrane is greater than 30%, and the thickness of the polyolefin microporous membrane is 0.02-0.07 mm. The fused cloth is a polypropylene / polyethylene glycol fused cloth, and the surface density of the fused cloth is 13 to 20 g / m 2 , the porosity is 81~96%, the liquid absorption capacity is greater than 500%, the thickness is 0.11~0.18mm, the number of fibers with a fiber fineness characteristic of 800nm or less accounts for 17~45%, and the fiber fineness characteristic is 800~2000nm The nu...

Embodiment 2

[0041] A wet-formed battery separator with controllable pore size. The battery separator is based on a three-layer composite film composed of polyolefin microporous film, melted cloth, and wet-laid non-woven fabric containing polyethylene short fibers. A composite membrane formed by radiation grafting of carboxyl and / or sulfonic acid functional groups.

[0042] Wherein, the polyolefin microporous membrane is a polyethylene microporous membrane, the porosity of the polyolefin microporous membrane is 50-60%, and the thickness of the polyolefin microporous membrane is 0.02-0.04mm. Described melting cloth is polypropylene / polyethylene glycol melting cloth, and the surface density of described melting cloth is 15~18g / m 2 , the porosity is 85~92%, the liquid absorption capacity is greater than 500%, the thickness is 0.13~0.16mm, the number of fibers whose fiber fineness characteristic is below 800nm accounts for 25~37%, and the fiber fineness characteristic is 800~2000nm The numb...

Embodiment 3

[0051] A wet-formed battery separator with controllable pore size. The battery separator is based on a three-layer composite film composed of polyolefin microporous film, melted cloth, and wet-laid non-woven fabric containing polyethylene short fibers. A composite membrane formed by radiation grafting of carboxyl and / or sulfonic acid functional groups.

[0052] Wherein, the polyolefin microporous membrane is a polyethylene microporous membrane, the porosity of the polyolefin microporous membrane is 55%, and the thickness of the polyolefin microporous membrane is 0.03 mm. Described fusion cloth is polypropylene / polyethylene glycol fusion cloth, and the surface density of described fusion cloth is 16.5g / m 2 , the porosity is 88.5%, the liquid absorption capacity is 505%, the thickness is 0.14mm, the number of fibers whose fiber fineness characteristic is below 800nm accounts for 31%, and the number of fibers whose fiber fineness characteristic is 800~2000nm accounts for 61%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com