Nano structure hydroxyapatite/titanium composite coating and preparing method thereof

A nano-hydroxyapatite and hydroxyapatite technology, applied in coating, nanotechnology, metal material coating technology and other directions, can solve the problems of polluting the human body, low proportion of titanium particles, and difficulty in forming composite coatings, etc. Achieve the effect of improving hardness and elastic modulus, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a nanostructured hydroxyapatite / titanium composite coating, comprising the following steps:

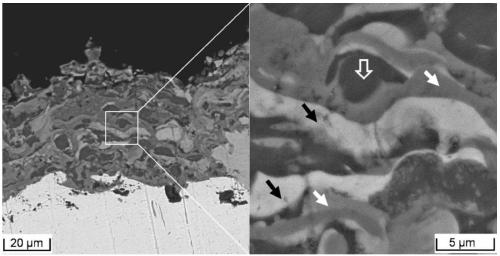

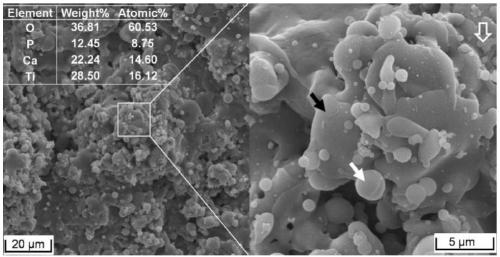

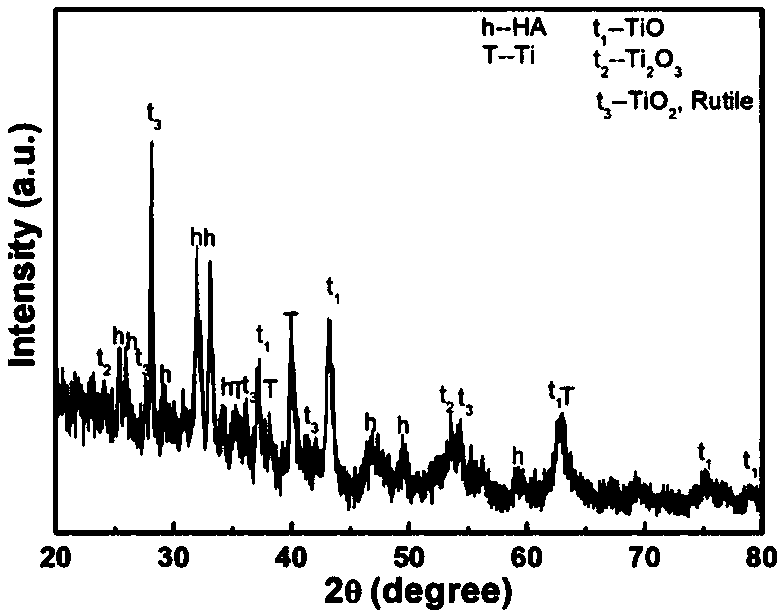

[0031] The nano-hydroxyapatite-titanium mixed particle suspension is mixed with atomizing gas, and the preheated substrate is sprayed by a supersonic flame spraying method to obtain a nano-structured hydroxyapatite / titanium composite coating.

[0032] The preparation method provided by the invention firstly needs to prepare nano-hydroxyapatite-titanium mixed particle suspension.

[0033] In the present invention, the solid content of the nano-hydroxyapatite-titanium mixed particle suspension is preferably 1-20%, more preferably 2-10%, and most preferably 4-8%. In the present invention, the nano-hydroxyapatite-titanium mixed particle suspension is preferably formed by mixing nano-hydroxyapatite, titanium particles and a solvent. In the present invention, the particle size of the nano-hydroxyapatite is preferably 5 nm-10 μm, more pre...

Embodiment 1

[0050] Preparation of nanostructured hydroxyapatite / titanium (mass ratio 7:3) composite coating on the surface of 316L stainless steel substrate

[0051] (1) Preparation of nano-hydroxyapatite-titanium mixed particle suspension: mix hydroxyapatite particles with an average particle size of 20 nm and titanium particles with an average particle size of 10 μm at a mass ratio of 7:3 to obtain a mixed powder ; The mixed powder was mixed with deionized water and absolute ethanol according to the mass ratio of 5:47.5:47.5 and mechanically stirred for 2 hours to obtain a suspension of nano-hydroxyapatite-titanium mixed particles;

[0052] (2) 316L stainless steel substrate preheating: adopt the supersonic flame spraying device to heat the substrate; the parameters of the heating are: the distance between the outlet end of the supersonic flame spraying spray gun and the surface of the substrate is 100mm, and the parallel movement speed of the spray gun relative to the substrate is 100mm...

Embodiment 2

[0060] Preparation of nanostructured hydroxyapatite / titanium (mass ratio 5:5) composite coating on the surface of 316L stainless steel substrate

[0061] (1) Preparation of nano-hydroxyapatite-titanium mixed particle suspension: mix hydroxyapatite particles with an average particle size of 20 nm and titanium particles with an average particle size of 10 μm at a mass ratio of 5:5 to obtain a mixed powder ; The mixed powder was mixed with deionized water and absolute ethanol according to the mass ratio of 5:47.5:47.5 and mechanically stirred for 2 hours to obtain a suspension of nano-hydroxyapatite-titanium mixed particles;

[0062] (2) 316L stainless steel substrate preheating: adopt the supersonic flame spraying device to heat the substrate; the parameters of the heating are: the distance between the outlet end of the supersonic flame spraying spray gun and the surface of the substrate is 100mm, and the parallel movement speed of the spray gun relative to the substrate is 100mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com