Regenerating process technology for producing high-quality low-pour-point lubricant base oil by full hydrogen method of waste lubricant oil

A technology for lubricating base oil and waste lubricating oil, which can be used in hydrotreating process, petroleum industry, lubricating composition, etc. The effect of high carbon value and long operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

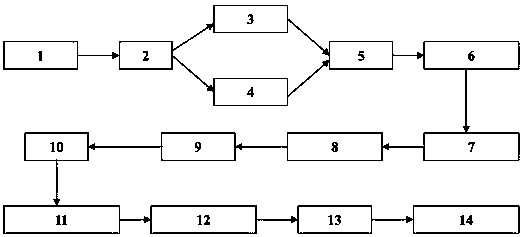

[0028] According to the waste lubricating oil regeneration scheme mentioned above, the hydrogenation reaction is carried out according to the material properties of the waste lubricating oil (see Table 1 for properties), and the product is high-quality lubricating oil base oil (see Table 2 for product properties), and the process conditions are as follows:

[0029] The reaction pressure of protective agent reactor 6 is 10Mpa, the reaction temperature is 320°C, and the total feed volume space velocity is 2h -1 , the hydrogen / oil volume ratio is 600:1; the reaction pressure of hydrofining reactor 7 is 10Mpa, the reaction temperature is 340°C, and the total feed volume space velocity is 0.6h -1 , the hydrogen / oil volume ratio is 600:1, and the catalyst loaded in the reactor is W-Mo-Ni / γ-Al 2 o 3 ;The reaction pressure of the isomerization depreciation reactor 11 is 10Mpa, the reaction temperature is 280°C, the hydrogen-oil ratio is 400:1, and the volume space velocity is 1.0h -...

Embodiment 2

[0031] According to the waste lubricating oil regeneration scheme mentioned above, the hydrogenation reaction is carried out according to the material properties of the waste lubricating oil (see Table 1 for properties), and the product is high-quality lubricating oil base oil (see Table 2 for product properties), and the process conditions are as follows:

[0032] The reaction pressure of protective agent reactor 6 is 13Mpa, the reaction temperature is 300°C, and the total feed volume space velocity is 1.5h -1 , the hydrogen / oil volume ratio is 400:1; the reaction pressure of hydrofining reactor 7 is 13Mpa, the reaction temperature is 360°C, and the total feed volume space velocity is 0.8h -1 , the hydrogen / oil volume ratio is 400:1, and the catalyst loaded in the reactor is Mo-Ni / γ-Al 2 o 3 ; The reaction pressure of the isomerization depreciation reactor 11 is 13Mpa, the reaction temperature is 260°C, the hydrogen-oil ratio is 500:1, and the volume space velocity is 0.8h ...

Embodiment 3

[0034] According to the waste lubricating oil regeneration scheme mentioned above, the hydrogenation reaction is carried out according to the material properties of the waste lubricating oil (see Table 1 for properties), and the product is high-quality lubricating oil base oil (see Table 2 for product properties), and the process conditions are as follows:

[0035] The reaction pressure of protective agent reactor 6 is 17Mpa, the reaction temperature is 310°C, and the total feed volume space velocity is 2.0h -1 , the hydrogen / oil volume ratio is 300:1; the reaction pressure of hydrofining reactor 7 is 17Mpa, the reaction temperature is 330°C, and the total feed volume space velocity is 0.9h -1 , the hydrogen / oil volume ratio is 300:1, and the catalyst loaded in the reactor is Mo-Ni / γ-Al 2 o 3 ; The reaction pressure of the isomerization depreciation reactor 11 is 17Mpa, the reaction temperature is 300°C, the hydrogen-oil ratio is 300:1, and the volume space velocity is 1.3h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com