Waterproof solar energy back plate glue

A solar backplane and waterproof technology, which is applied in the direction of adhesives, epoxy glue, adhesive types, etc., can solve the problems of water resistance and bond strength that cannot be further improved, so as to reduce self-aggregation and improve waterproofness and the effect of improving bond strength and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

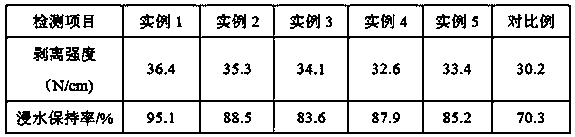

Examples

example 1

[0031] Mix graphene oxide and water in a beaker at a mass ratio of 1:200, and ultrasonically disperse for 40 minutes at a frequency of 55 kHz to obtain a graphene oxide dispersion. The graphene oxide dispersion and hydrazine hydrate are mixed at a mass ratio of 100 : 1 mixed in a flask, and adding 0.08 times the weight of the graphene oxide dispersion to the flask with 28% ammonia water, at a temperature of 90°C and a rotating speed of 400r / min, stirring and reacting for 180min, then filtering , to obtain a filter cake, the filter cake was vacuum-dried at a temperature of 65°C for 5 hours to obtain pretreated graphene, and the pretreated graphene and ethanol were mixed in a three-necked flask at a mass ratio of 1:100, and poured into a three-necked Sodium hydroxide with 3 times the mass of pretreated graphene and cationic surfactant with 2 times the mass of pretreated graphene were added to the flask. Under the condition of frequency of 55kHz, after ultrasonic dispersion for 40...

example 2

[0033]Mix graphene oxide and water in a beaker at a mass ratio of 1:200, and ultrasonically disperse for 40 minutes at a frequency of 55 kHz to obtain a graphene oxide dispersion. The graphene oxide dispersion and hydrazine hydrate are mixed at a mass ratio of 100 : 1 mixed in a flask, and adding 0.08 times the weight of the graphene oxide dispersion to the flask with 28% ammonia water, at a temperature of 90°C and a rotating speed of 400r / min, stirring and reacting for 180min, then filtering , to obtain a filter cake, the filter cake was vacuum-dried at a temperature of 65°C for 5 hours to obtain pretreated graphene, and the pretreated graphene and ethanol were mixed in a three-necked flask at a mass ratio of 1:100, and poured into a three-necked Sodium hydroxide with 3 times the mass of pretreated graphene and cationic surfactant with 2 times the mass of pretreated graphene were added to the flask. Under the condition of frequency of 55kHz, after ultrasonic dispersion for 40m...

example 3

[0035] In parts by weight, take in turn: 50 parts of epoxy resin, 20 parts of ethylene-vinyl acetate copolymer, 5 parts of turpentine, 16 parts of phosphorus oxychloride, 22 parts of graphene, 15 parts of polyaspartic acid ester, 8 parts of epoxy soybean oil, 12 parts of isocyanate, 15 parts of carbonate and 80 parts of solvent, mix epoxy resin and solvent in a blender, and add ethylene-vinyl acetate copolymer, turpentine, phosphorus oxychloride to the blender , graphene, polyaspartate, epoxidized soybean oil, isocyanate and carbonate, under the conditions of temperature 30°C and rotation speed 400r / min, after stirring and mixing for 60min, a waterproof solar backsheet adhesive was obtained. Described epoxy resin is epoxy resin E-44. The isocyanate is toluene diisocyanate. The carbonate is zinc carbonate. Described solvent is toluene. Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com