Steel structure surface curing film

A technology for curing film and steel structure, applied in the direction of film/flake adhesive, adhesive, etc., can solve problems such as hidden danger of steel structure and safety impact of steel structure building, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

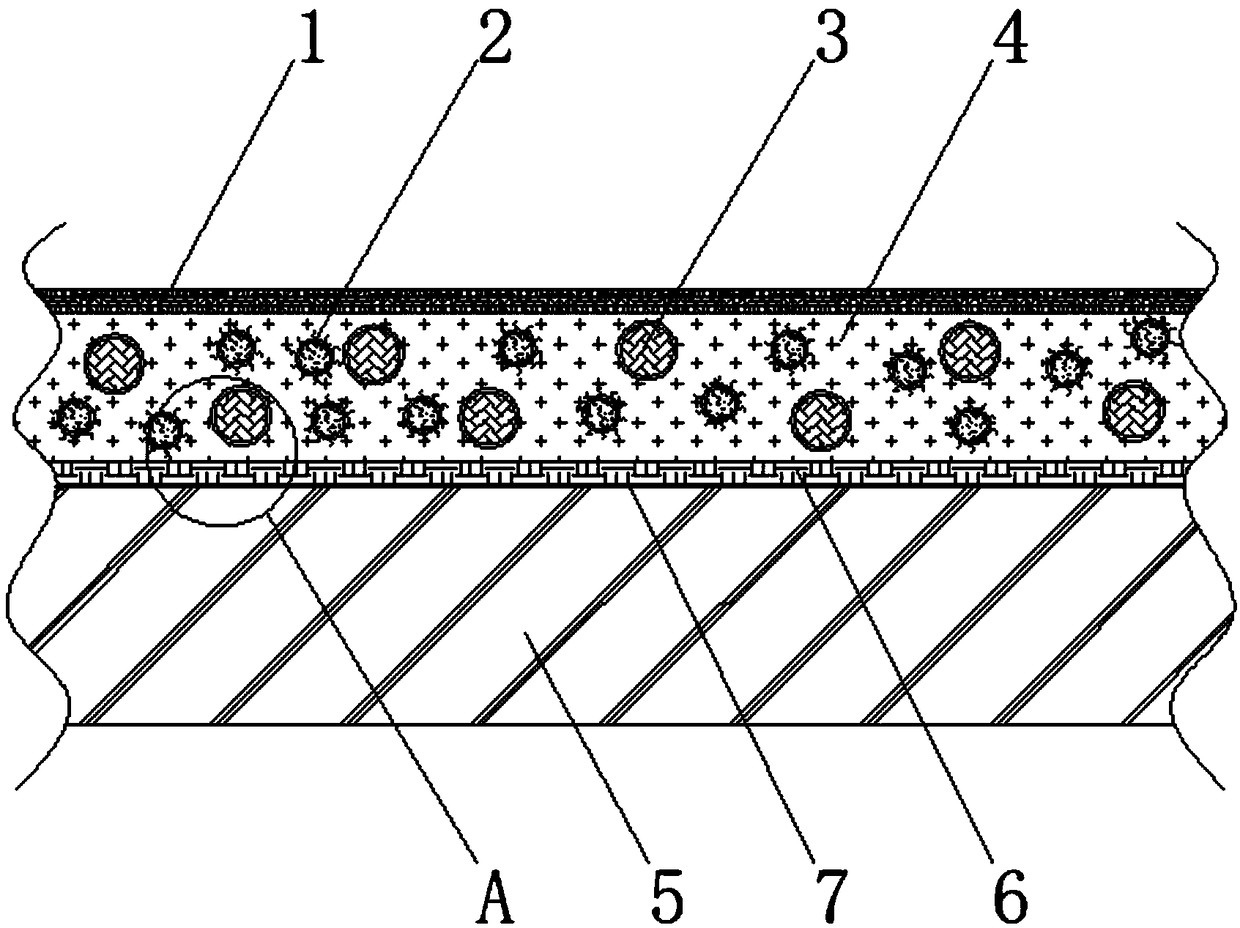

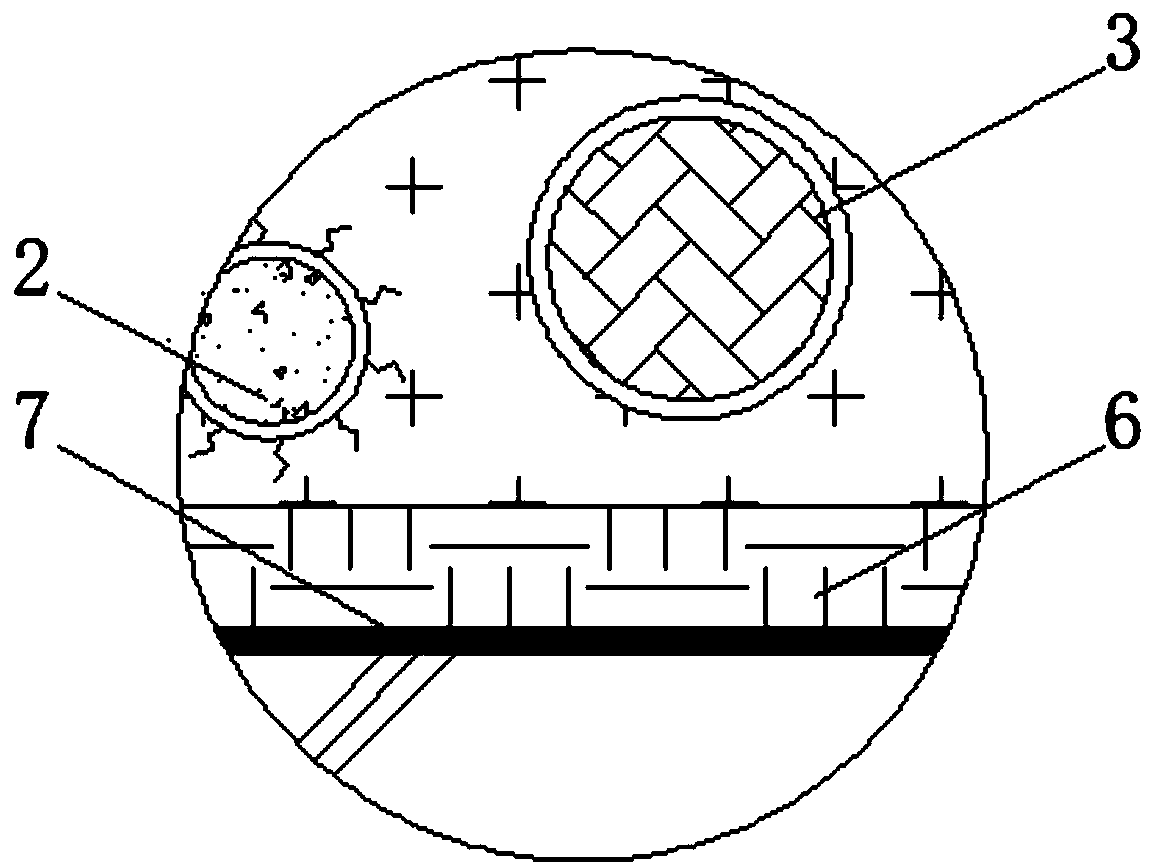

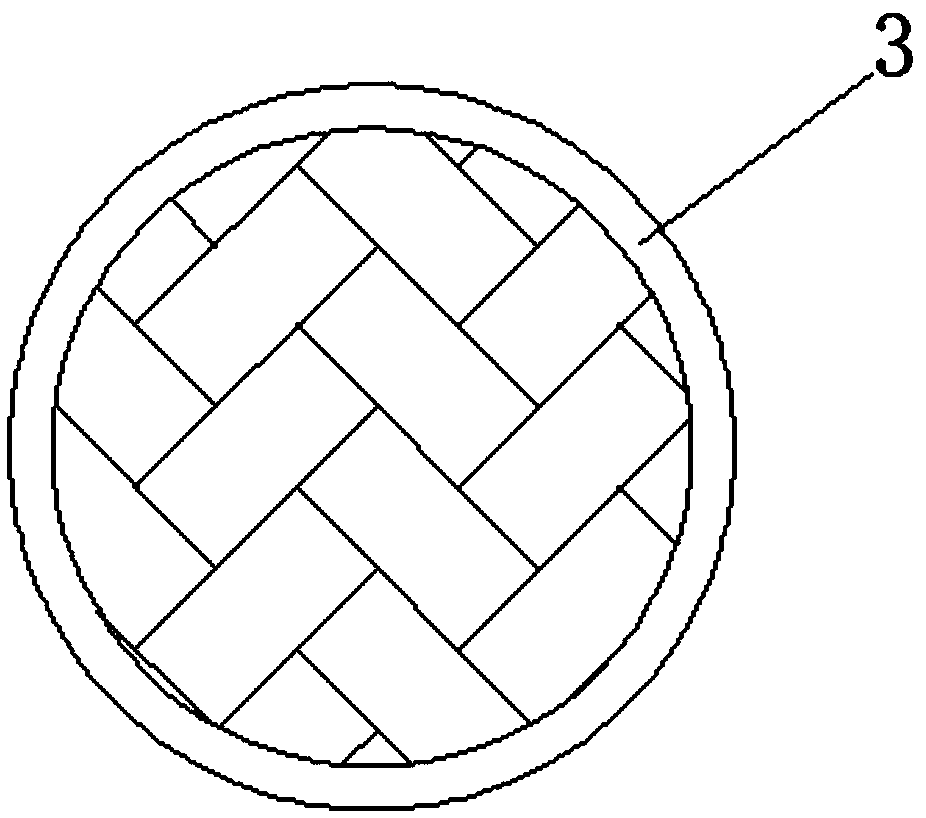

[0041] see Figure 1-7 , a steel structure surface maintenance film, comprising a solid outer end release film 1 and a single water permeable composite fiber film 6, the solid outer end release film 1 and the single water permeable composite fiber film 6 are fixedly connected, the solid outer end release film 1 and the single water permeable composite fiber film 6 are fixedly connected Between the single water-permeable composite fiber film 6, there are film damage repair balls 2 and water-absorbing composite fiber resin balls 3. The film damage repair balls 2 are evenly arranged in the solid outer end release film 1 and the single water-permeable composite fiber film 6, and the water-absorbing compound The fiber resin balls 3 are evenly arranged in the solid outer end release film 1 and the single water-permeable composite fiber film 6, and the space between the solid outer end release film 1 and the single water-permeable composite fiber film 6 is filled with polymer hygrosco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com