A kind of organic zinc vulcanization activator and preparation method thereof

A vulcanization activator and organic zinc technology, which is applied in the field of organic zinc vulcanization activator and its preparation, can solve the problems of high price and limited zinc reduction ability, and achieve the effects of low price, lower specific gravity and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In a 500mL three-necked flask equipped with a stirring and reflux device, add 85mmol (8.4g) of zinc hydroxide, 50mmol (6.1g) of benzoic acid and 280g of methylcyclohexane, and reflux at 102°C for 60min, cool and filter with suction The solvent was recovered and dried to obtain 13.4 g of a white powdery organozinc vulcanization active agent with a zinc content of 40.8%.

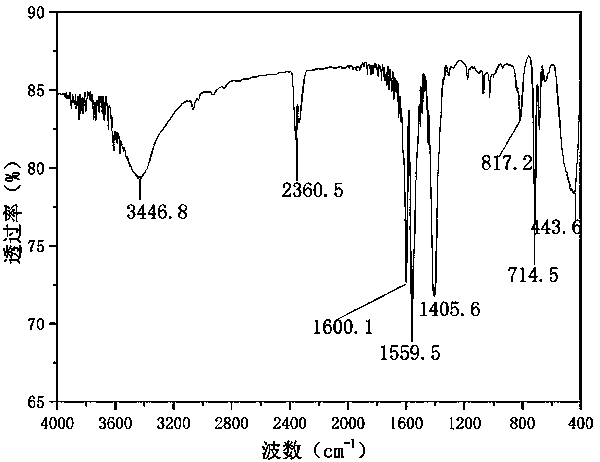

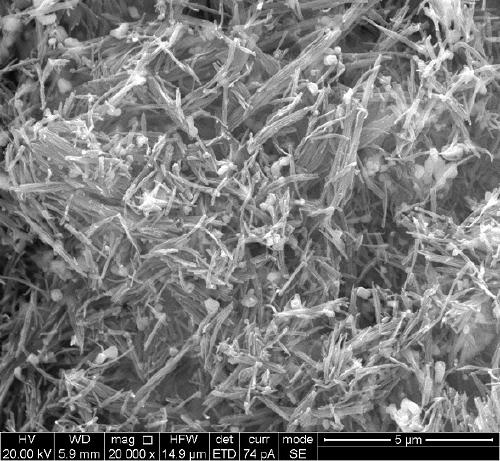

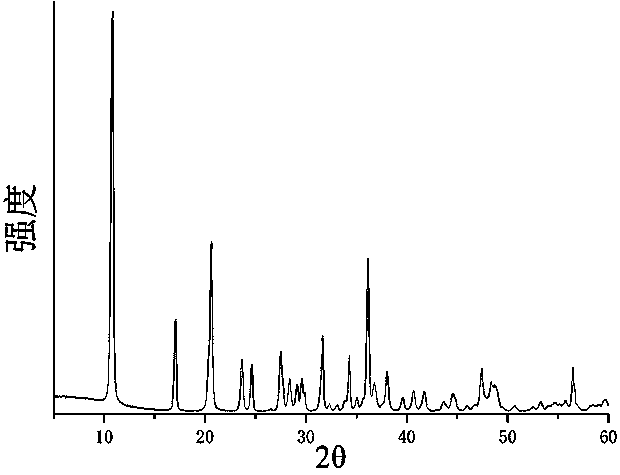

[0017] The FT-IR spectrum of this organozinc vulcanization activator is shown in figure 1 shown. Its microscopic appearance is elongated fibers mixed with a small amount of random particles, see figure 2 SEM photographs shown. XRD pattern see image 3 , Figure 4 is the TG-DTA spectrum.

Embodiment 2

[0019] In a 5L kneading reactor equipped with a reflux device, add 12mol (1193g) of zinc hydroxide, 7.5mol (916g) of benzoic acid and 1200g of n-heptane, stir and reflux at 99°C for 90min, then evaporate and recover the solvent to obtain a white Powdered organozinc vulcanization activator 1956g, zinc content 41.4%.

[0020] The organozinc activator synthesized in Examples 1 and 2, comparative example α-ethylhexanoic acid zinc and comparative example 99.7% indirect method zinc oxide are applied in all-steel radial tire tread rubber, and the compound formula is as follows (by weight ): 100 parts of SMR10; 40 parts of carbon black N339; 20 parts of precipitated silica; 2 parts of aromatic oil; 2 parts of protective wax; 1.5 parts of stearic acid; 1 part of silane coupling agent si69; 2 parts of agent 4020; 2.5 parts of sulfur powder; 1.5 parts of accelerator CZ; 0.5 parts of accelerator DM; 2.5 parts of vulcanization activator.

[0021] The tread rubber mixing process adopts a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com