Anti-acid pipeline clad steel plate with corrosion resistance and manufacturing method of anti-acid pipeline clad steel plate

A corrosion-resistant, composite steel plate technology, applied in metal rolling and other directions, can solve the problems of reduced impact toughness and DWTT performance of composite steel plate substrates, inability to guarantee stainless steel corrosion resistance, and failure to meet pipeline technical requirements, and achieve excellent pitting corrosion. , good overall mechanical properties, the effect of meeting the requirements of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

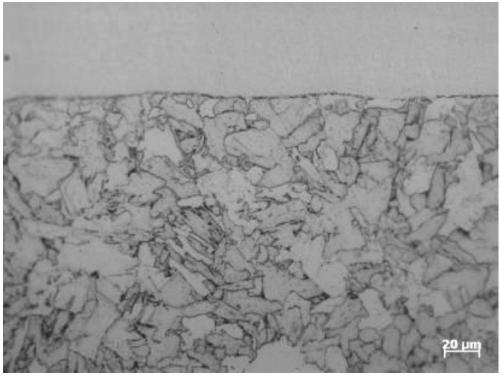

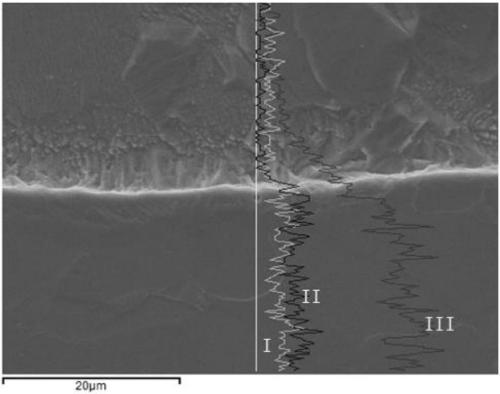

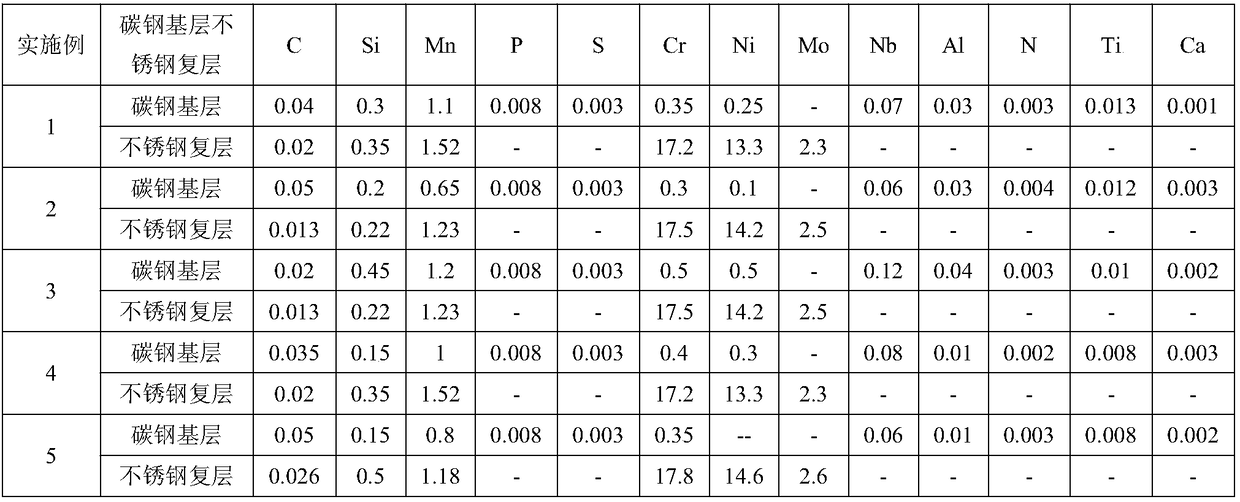

[0058] Table 1 lists the mass percentage of each chemical element in the corrosion-resistant composite steel plate for acid-resistant pipelines in Examples 1-5.

[0059] Table 1. (wt%, the balance is Fe and other unavoidable impurity elements except P, S, N)

[0060]

[0061] The manufacturing method of the corrosion-resistant acid-resistant pipeline composite steel plate of embodiment 1-5 comprises steps:

[0062] (1) Obtain carbon steel base billets and stainless steel clad billets or steel plates;

[0063] (2) Symmetric billets;

[0064] (3) Symmetrical rolling: reheating at 1100-1200°C, rolling after austenitization is sufficient, rolling is divided into the first stage of rolling in the recrystallization zone and the second stage of rolling in the non-recrystallization zone, of which In the first stage of rolling in the recrystallization area, the starting rolling temperature is lower than 1200°C, and the finishing rolling temperature is above 1,000°C; in the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Shock value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com