Cement-based elastic grouting material suitable for repairing concrete cracks in deep water and preparation method thereof

A grouting material and elastic technology, which is used in the field of repairing concrete cracks in hydraulic engineering to achieve the effects of low body shrinkage, high impact toughness and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

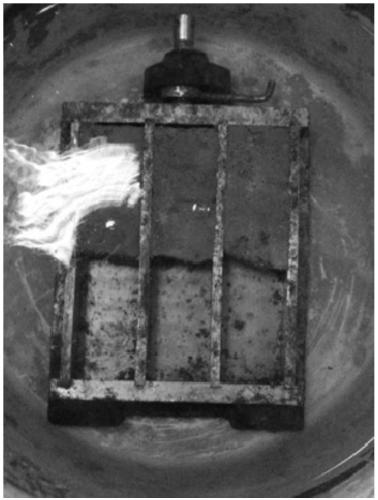

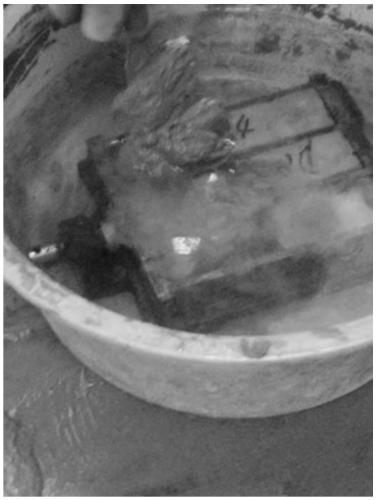

Image

Examples

Embodiment 1

[0059] According to weight percentage, prepare the following materials: cement 21.5%, slag powder 19.4%, silicon powder 4.3%, gypsum powder 6.5%, rubber powder 10.8%, naphthalene sulfonate water reducer 1.3%, water-based acrylate emulsion 15.5%, Water-based epoxy curing agent 3.0%, polyester fiber 0.4%, water 17.3%.

[0060] The preparation method of above-mentioned deep water elastic grouting material, comprises the steps:

[0061] In the first step, the cement, slag powder, silicon powder, gypsum powder, rubber powder, and polyester fiber are weighed and stirred evenly, as the mixture A; in the second step, the water-based curing agent is added to water and diluted in equal proportions (this step The weight of the water used is not included in the above proportion weight), then add it to the water-based acrylate emulsion and stir evenly, as the mixture B; in the third step, add the mixture B to the mixture A, then add water and stir evenly to obtain the cement-based Elastic...

Embodiment 2

[0064] According to weight percentage, prepare the following materials: cement 20.7%, slag powder 18.7%, silicon powder 4.1%, gypsum powder 6.2%, rubber powder 10.4%, naphthalenesulfonate water reducer 1.2%, water-based acrylate emulsion 14.9%, Water-based epoxy curing agent 4.6%, polyester fiber 0.4%, water 18.8%.

[0065] The preparation method of above-mentioned deep water elastic grouting material, comprises the steps:

[0066] In the first step, the cement, slag powder, silicon powder, gypsum powder, rubber powder, and polyester fiber are weighed and stirred evenly, as the mixture A; in the second step, the water-based curing agent is added to water and diluted in equal proportions (this step The weight of the water used is not included in the above proportion weight), then add it to the water-based acrylate emulsion and stir evenly, as the mixture B; in the third step, add the mixture B to the mixture A, then add water and stir evenly to obtain the cement-based Elastic ...

Embodiment 3

[0069] According to weight percentage, prepare the following materials: cement 22.0%, slag powder 19.8%, silicon powder 4.4%, gypsum powder 6.6%, rubber powder 11.0%, naphthalenesulfonate water reducer 1.3%, water-based acrylate emulsion 21.1%, Water-based epoxy curing agent 2.2%, polyester fiber 0.4%, water 11.2%.

[0070] The preparation method of above-mentioned deep water elastic grouting material, comprises the steps:

[0071] In the first step, the cement, slag powder, silicon powder, gypsum powder, rubber powder, and polyester fiber are weighed and stirred evenly, as the mixture A; in the second step, the water-based curing agent is added to water and diluted in equal proportions (this step The weight of the water used is not included in the above proportion weight), then add it to the water-based acrylate emulsion and stir evenly, as the mixture B; in the third step, add the mixture B to the mixture A, then add water and stir evenly to obtain the cement-based Elastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com