Continuous production technology of fiber reinforced polyurethane foam plastic plate

A technology of foam plastics and fiber reinforcement, applied in applications, household appliances, flat products, etc., can solve problems such as quality decline, shortage of raw materials, and insufficient feasible alternative materials, and achieve stable quality, continuous and stable production, and suitable for large-scale continuous production. The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

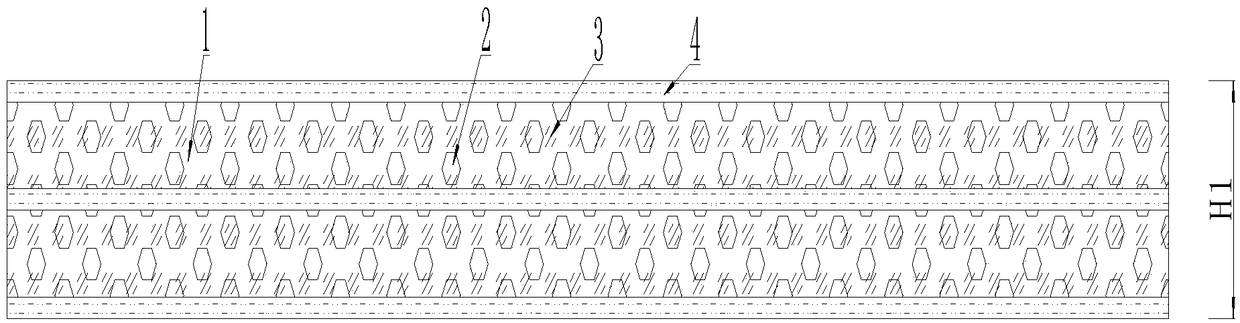

[0032] A resin matrix 1 is arranged between at least two fiber mats 4 parallel to each other, continuous fibers 2 and chopped fibers 3 are evenly distributed in the resin matrix 1, continuous fibers 2 in two adjacent rows are arranged alternately, and the fiber mats located under the resin matrix 1 The distance between the bottom end of 4 and the top end of the fiber mat 4 above the resin matrix 1 is H1, and H1 is 5-50 mm;

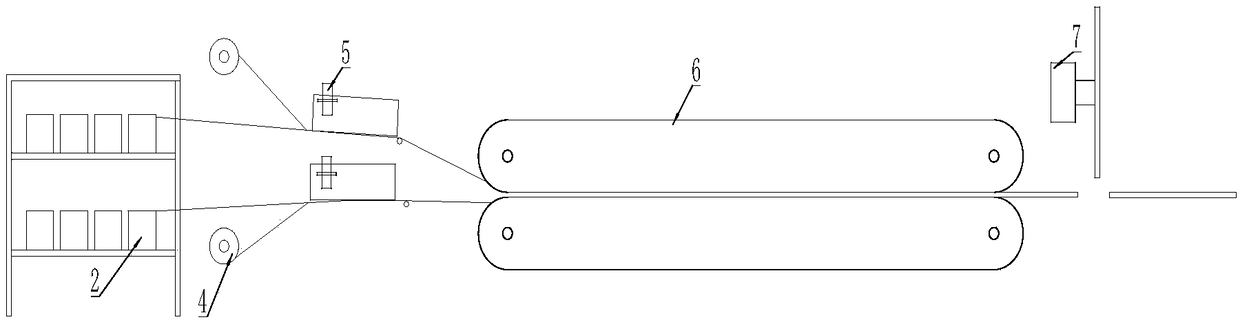

[0033] A continuous production process of fiber-reinforced polyurethane foam plastic sheet, the process flow is: continuous fiber arrangement→casting resin matrix material→adding chopped fibers→uniform infiltration of reinforcing material and resin matrix material→foaming and curing forming→cutting to length;

[0034] The first step, continuous fiber arrangement: the continuous fiber 2 is evenly distributed between two fiber mats 4 according to the specified order, and the arranged continuous fiber 2 and fiber mat 4 are transported to the lamination conveyo...

Embodiment 2

[0041] The continuous fibers 2 and the chopped fibers 3 are glass fibers, or aramid fibers, or basalt fibers, or carbon fibers, one or more than one of which are combined.

Embodiment 3

[0043] The resin matrix 1 adopts rigid polyurethane foam, or cross-linked polyvinyl chloride foam, or polyetherimide foam, or polyacrylonitrile foam, or polyester foam, one of them; The agent adopts any one or a combination of foaming agent, flame retardant, foam stabilizer, antioxidant, ultraviolet absorber and catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com