Preparation method for charcoal-loaded graphite phase carbon nitride composite photocatalyst capable of degrading petroleum hydrocarbon, and application thereof

A graphite phase carbon nitride and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, restoration of polluted soil, etc., can solve rare problems, achieve ideal yield, high specific surface area, low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

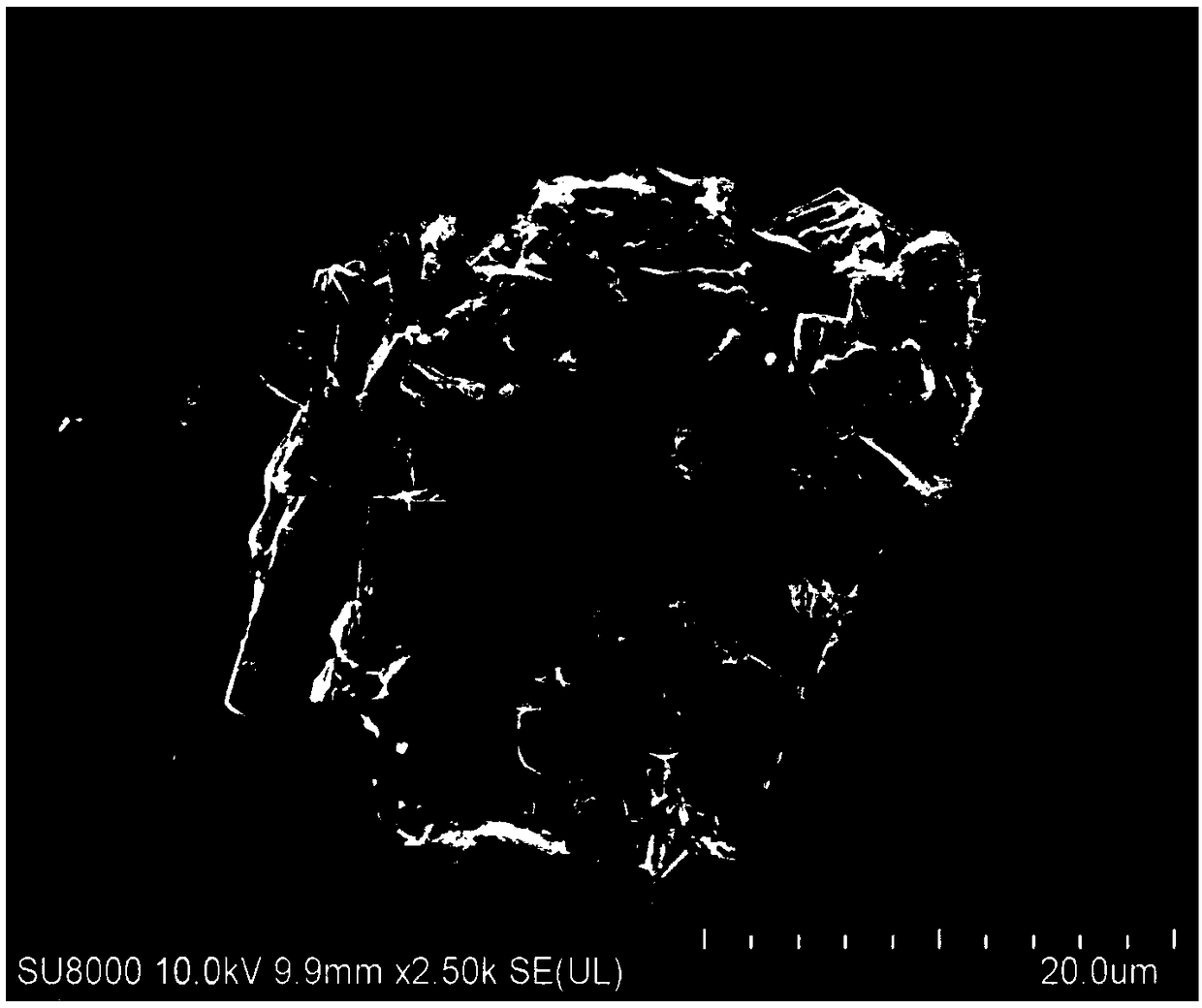

Image

Examples

Embodiment 1

[0038] (1) Preparation of biochar: Soybean stalks in Northeast China were collected, ears, leaves and surface ash on the outer surface were removed, rinsed with deionized water, dried at 70°C, crushed, and passed through a 60-mesh sieve. Weigh 30g of the above soybean stalk powder into an atmosphere furnace, calcinate at 500°C for 3h, and treat with 1mol / L hydrochloric acid to remove ash, wash with deionized water until neutral, dry overnight, and seal and store to obtain this black powder solid Recorded as biochar.

[0039] (2) Preparation of a mixture of biochar and melamine: Take 0.5 g of biochar and 0.5 g of melamine prepared in step (1), grind them for 1 hour until they are evenly mixed, and obtain a mixture of biochar and melamine.

[0040] (3) Preparation of biochar-supported graphite-phase carbon nitride composite photocatalyst: Measure 5 g of the mixture of biochar and melamine obtained in step (2), put it into an atmosphere furnace, and calcinate at 520°C for 4 hours...

Embodiment 2

[0044](1) Preparation of biochar: Soybean stalks in Northeast China were collected, ears, leaves and surface ash on the outer surface were removed, rinsed with deionized water, dried at 70°C, crushed, and passed through a 60-mesh sieve. Weigh 30g of the above-mentioned soybean straw powder into an atmosphere furnace, calcinate at 500°C for 3h, weigh the obtained black powder, treat with 1mol / L hydrochloric acid to remove ash, wash with deionized water until neutral, dry overnight, and seal Preserve, this black powder solid that obtains is recorded as biochar.

[0045] (2) Preparation of a mixture of biochar and melamine: Take 1 g of biochar prepared in step (1) and 2 g of melamine, grind them for 1 hour until they are evenly mixed, and obtain a mixture of biochar and melamine.

[0046] (3) Preparation of biochar-supported graphite-phase carbon nitride composite photocatalyst: Measure 5 g of the mixture of biochar and melamine obtained in step (2), put it into an atmosphere fur...

Embodiment 3

[0050] (1) Preparation of biochar: Soybean stalks in Northeast China were collected, ears, leaves and surface ash on the outer surface were removed, rinsed with deionized water, dried at 70°C, crushed, and passed through a 60-mesh sieve. Weigh 30g of the above-mentioned soybean straw powder into an atmosphere furnace, calcinate at 520°C for 4h, weigh the obtained black powder, treat with 1mol / L hydrochloric acid to remove ash, wash with deionized water until neutral, dry overnight, and seal Preserve, this black powder solid that obtains is recorded as biochar.

[0051] (2) Preparation of a mixture of biochar and melamine: Take 1 g of biochar prepared in step (1) and 4 g of melamine, grind them for 1 hour until they are evenly mixed, and obtain a mixture of biochar and melamine.

[0052] (3) Preparation of biochar-supported graphite-phase carbon nitride composite photocatalyst: Measure 5 g of the mixture of biochar and melamine obtained in step (2), put it into an atmosphere fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cut length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com