Full bio-based polylactic acid foaming material and preparation method thereof

A polylactic acid foaming, all-biological technology, applied in the field of polymer material processing and microcellular foaming, can solve the problems of poor performance uniformity and mechanical properties of blends, difficult recycling and dispersing of polylactic acid, etc. Improve melt strength and crystallization performance, improve melt performance and crystallization rate, and effect of uniform cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of full bio-based polylactic acid foam material, the steps are as follows:

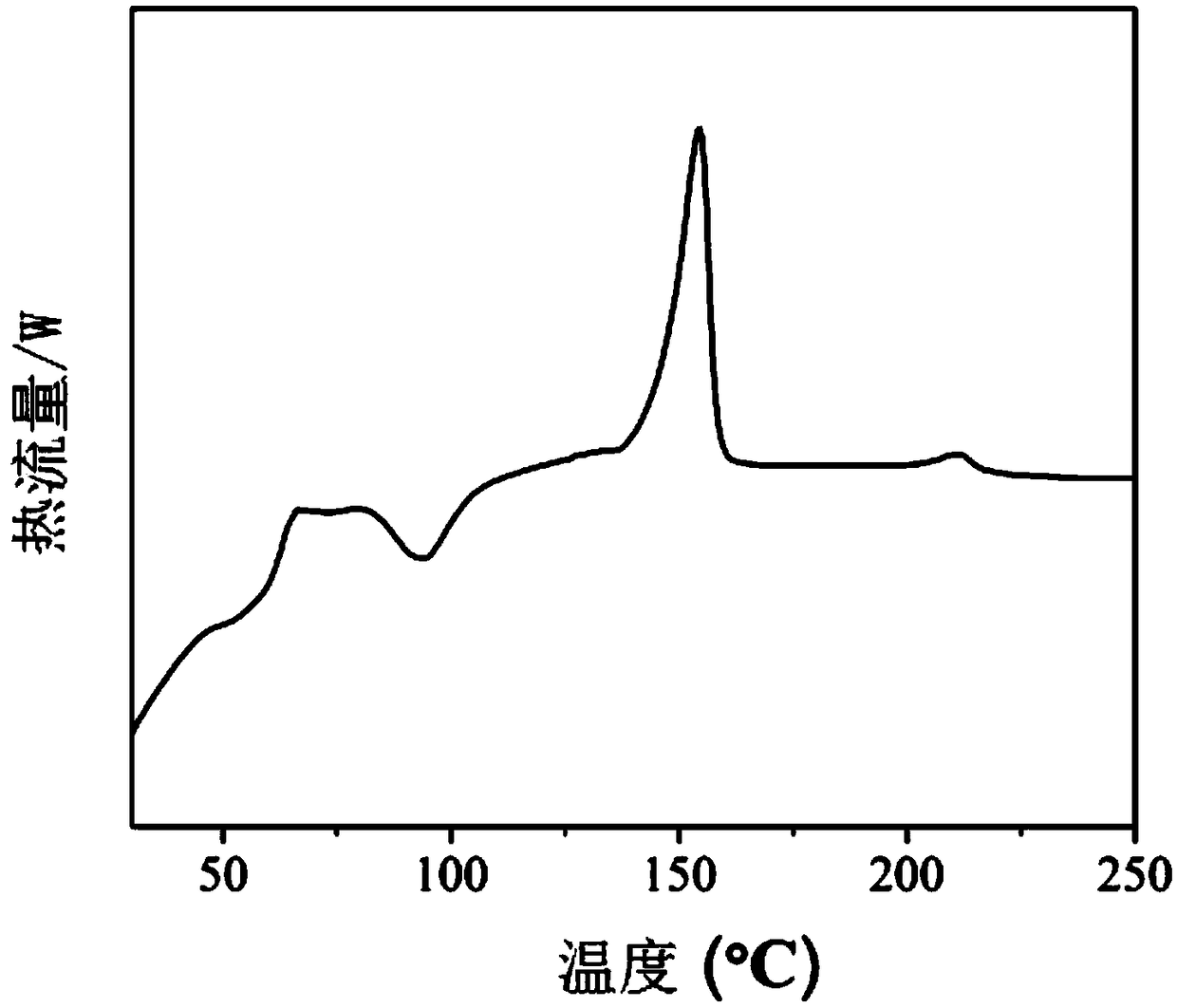

[0039] (1) First dry the L-polylactic acid and the D-polylactic acid at 60-80°C for 6-8 hours, and then mix the dried L-lactic acid and the D-polylactic acid at a mass ratio of 90-99:10-1, Finally, the mixture is added to a twin-screw extruder for melt blending and drying to obtain polylactic acid containing stereocomplex crystals; the screw temperature of the twin-screw extruder is 140-180°C, and the screw speed is 50-150rpm; the melting zone temperature 140-200°C;

[0040] (2) Put the polylactic acid into an extrusion foaming machine at 140-200°C to melt it, then feed the foaming agent gas into the screw from the gas injection port metering pump on the extrusion foaming machine, and mix it with the polylactic acid melt Uniform, forming a single-phase polymer / gas melt;

[0041] (3) Reduce the temperature of the screw from the gas injection port to the machine head, so th...

Embodiment 1

[0046] (1) Blend the dried L-polylactic acid and D-polylactic acid at a mass ratio of 99:1, wherein the weight average molecular weight of the two is 15, and the corresponding isomer content is 1%. The screw extruder melts and blends, the screw temperature is 140-180° C., and the screw rotation speed is 50 rpm to obtain polylactic acid containing stereocomplex crystals.

[0047] (2) Put the dried polylactic acid containing stereocomplex crystals into an extrusion foaming machine to melt at a temperature of 140-200°C. At the same time, supercritical nitrogen accounting for 0.5% of the mass of polylactic acid is fed into the screw by a metering pump at the gas injection port on the extruder, and mixed evenly with the polymer melt to form a single-phase polymer / gas solution.

[0048] (3) Reduce the temperature of the screw from the gas injection port to the machine head, so that the melt temperature at the machine head is 110°C, and the pressure at the machine head is 8MPa. Final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average cell diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com