Special cleaning agent for ladle furnace lining and its application method

A cleaning agent and ladle technology, which is applied in the field of metallurgical auxiliary materials, can solve the problems of no ladle lining cleaning agent, etc., and achieve the effects of ensuring continuous smelting capacity, preventing slag accumulation, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

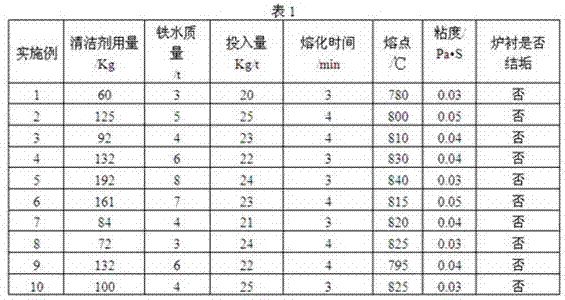

Examples

Embodiment 1

[0025] A special cleaning agent for ladle furnace lining, comprising the following raw materials in percentage by weight: 38% of premelt, 25% of sodium oxide, 20% of fluorite powder, 10% of calcite powder, and 7% of soda-lime glass.

[0026] The premelt in the special cleaning agent for ladle furnace lining is composed of the following raw materials in weight percentage: 40% of quartz, 29% of limestone, 20% of soda ash, and 11% of clay.

[0027] The chemical composition and mass percentage of the special cleaning agent for ladle furnace lining are SiO 2 25%, Al 2 o 3 2%, CaO30%, MgO3%, Na 2 O 25%, F - 15%, its particle size is 18 mesh, its moisture content is 0.4%, its melting point is 780°C, and its viscosity at 1300°C is 0.03 Pa•S.

[0028] In the actual production process, after injecting molten iron with a mass of 3 t into the ladle, 60 Kg of the special cleaning agent for the ladle furnace lining of this embodiment is sprinkled on the surface of the molten iron. Aft...

Embodiment 2

[0030] A special cleaning agent for ladle furnace lining, comprising the following raw materials in percentage by weight: 40% of premelt, 23% of sodium oxide, 18% of fluorite powder, 11% of calcite powder, and 8% of soda-lime glass.

[0031] The premelt in the special cleaning agent for ladle furnace lining is composed of the following raw materials in weight percentage: 45% of quartz, 19% of limestone, 21% of soda ash, and 15% of clay.

[0032] The chemical composition and mass percentage of the special cleaning agent for ladle furnace lining are SiO 2 35%, Fe 2 o 3 2%, CaO25%, MgO1%, Na 2 O 18%, F - 19%, its particle size is 80 mesh, its moisture content is 0.5%, its melting point is 800°C, and its viscosity at 1300°C is 0.05 Pa•S.

[0033] In the actual production process, after injecting molten iron with a mass of 5 t into the ladle, 125 Kg of the special cleaning agent for ladle furnace lining of this embodiment is sprinkled on the surface of the molten iron. After ...

Embodiment 3

[0035] A special cleaning agent for ladle furnace lining, comprising the following raw materials in percentage by weight: 35% of premelt, 27% of sodium oxide, 22% of fluorite powder, 10% of calcite powder, and 6% of soda-lime glass.

[0036] The premelt in the special cleaning agent for ladle furnace lining is composed of the following raw materials in weight percentage: 50% of quartz, 20% of limestone, 20% of soda ash, and 10% of clay.

[0037] The chemical composition and mass percentage of the special cleaning agent for ladle furnace lining are SiO 2 27%, Al 2 o 3 1%, Fe 2 o 3 2%, CaO 28%, Na 2 O 25%, F - 17%, its particle size is 30 mesh, its moisture content is 0.3%, its melting point is 810°C, and its viscosity at 1300°C is 0.04 Pa•S.

[0038] In the actual production process, after injecting molten iron with a mass of 4 tons into the ladle, 92 Kg of the special cleaning agent for the ladle furnace lining of this embodiment is sprinkled on the surface of the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com