A device and method for preparing large-scale ultra-high-strength aluminum alloy continuous casting ingot

An ultra-high-strength, aluminum alloy technology, which is applied in the metal continuous casting process and the metal material processing field, can solve problems such as inability to solve large-size ingots, inability to improve temperature field, and inability to reduce liquid cavities, so as to improve material utilization, The device is simple, convenient and feasible, and the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

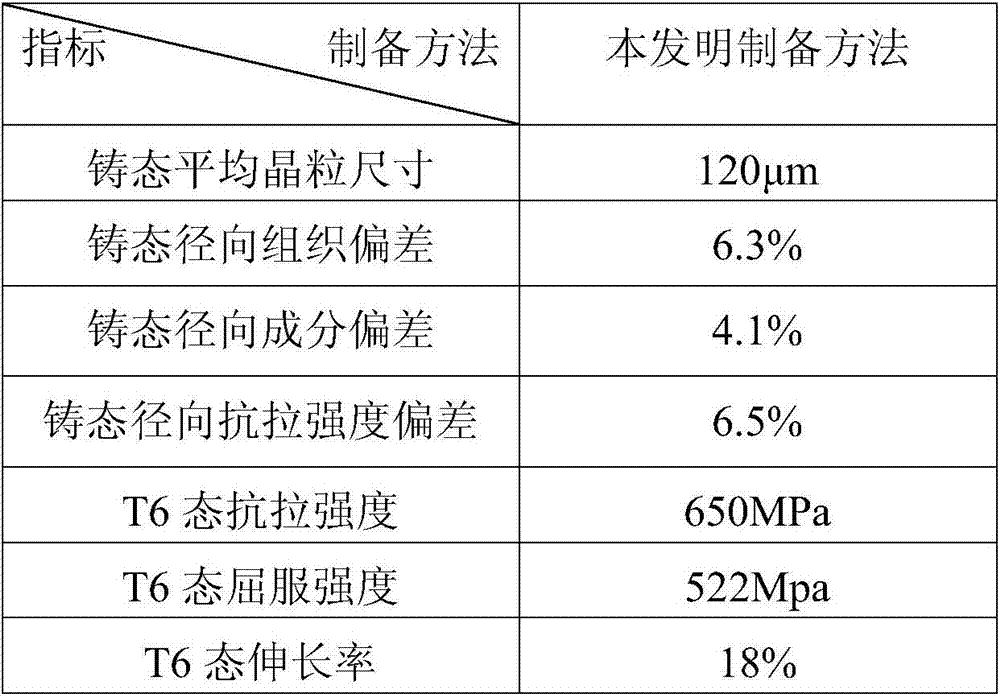

Embodiment 1

[0045] A research institution is working on a military project, developing 7075 aluminum alloy cast rods with a diameter of 500mm, and then extruding them into "S"-shaped products with a thickness of 10mm and a length of 10,000mm through a porous die, and the extrusion ratio is 20, and the product reaches the corresponding performance after post-heat treatment Indicators, the project has strict requirements on the quality of cast rods, extruded products and final products: (1) The surface quality of cast rods is required to be free of surface defects such as scratches, cracks, deep cold shuts, and large segregation tumors. Cracking: There are strict requirements on the uniformity of the internal structure, composition and performance of the ingot. In the center of the center of the upper radial side, the grain size deviation is required to be controlled within 8%, the composition deviation is controlled within 6%, and the tensile strength is controlled within 8%. ; Grain size T...

Embodiment 2

[0052] A university cooperated with a company to prepare a 7050 round ingot with a diameter of 650mm and a length of 2000mm, which has high requirements for the quality of the ingot. The main requirements are the uniformity and cracking of the ingot, and the control of the deviation of the mechanical properties of the radial structure of the ingot. Within 6%, and there should be no large wrinkles on the surface, the cutting amount should be less than 3mm, there should be no cracking, and the qualified rate should be controlled at 90%. The project is going to be done by ordinary electromagnetic stirring casting method.

[0053] The present invention has characteristics superior to ordinary electromagnetic stirring technology in many respects. In this embodiment, the ordinary electromagnetic casting technology and the method of the present invention are compared with the ingot casting requirements for the preparation project, and the specific casting implementation is as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com