Antistatic flame-retardant master batch and preparation method thereof

A flame retardant masterbatch and antistatic technology, which is applied in the field of antistatic flame retardant masterbatch and its preparation, can solve the problems of limited carbon black addition, impact on pressure bearing performance, and high comprehensive cost, so as to reduce shear damage and ensure Hydrostatic strength, the effect of reducing the number of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

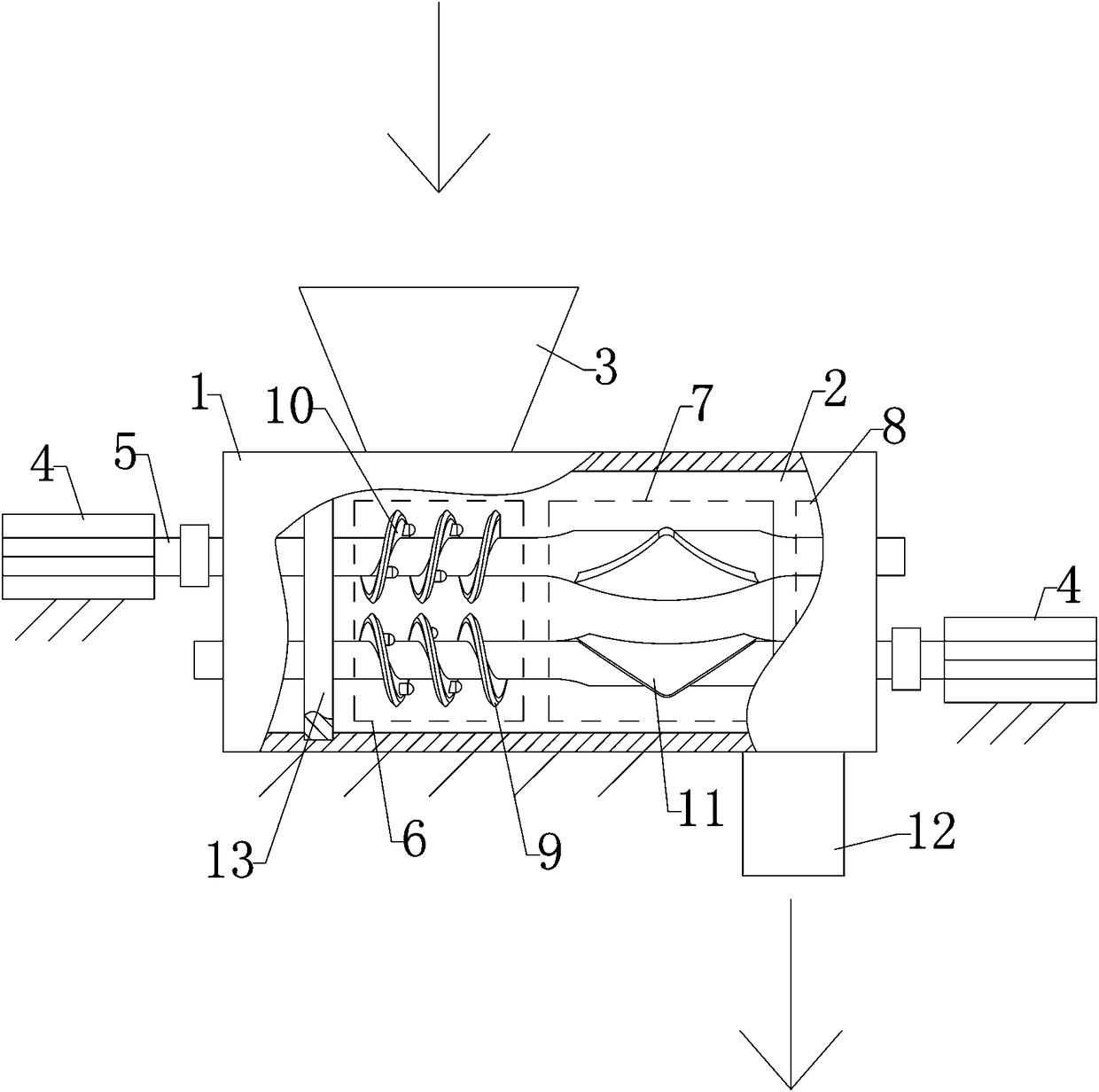

Method used

Image

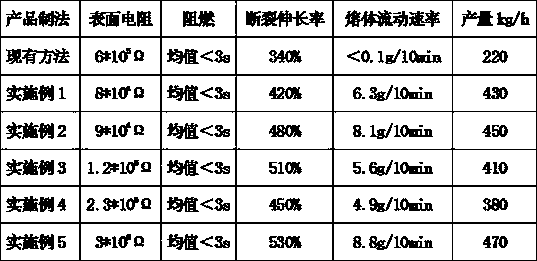

Examples

Embodiment 1

[0021] An antistatic flame retardant masterbatch, mainly comprising the following components in parts by mass: 48 parts of LLDPE, 10 parts of EVA, 5 parts of POE, 12 parts of conductive carbon black, 3 parts of coated red phosphorus, processed The auxiliary agent is 1.5 parts, and the compatibilizer is 10 parts.

[0022] LLDPE is used as the matrix resin prepared by antistatic and flame retardant masterbatch. It mainly melts and mixes conductive carbon black, coated red phosphorus, compatibilizer, etc. in the formula to form a blended state of various components, and utilizes linear polymer The characteristic of many side chains in the ethylene molecular chain maintains the mechanical properties of the mixture.

[0023] Due to the introduction of vinyl acetate monomer into the molecular chain of EVA, the crystallinity is reduced, the flexibility, impact resistance and filler compatibility are improved, and the compatibility between conductive carbon black and polyethylene resi...

Embodiment 2

[0042] An antistatic flame retardant masterbatch, mainly comprising the following components in parts by mass: 20 parts of LLDPE, 2 parts of EVA, 3 parts of POE, 7 parts of conductive carbon black, 3.5 parts of coated red phosphorus, processed The auxiliary agent is 0.1 part, and the compatibilizer is 2 parts.

[0043] Preferably, the LLDPE is linear low density polyethylene, the state of the linear low density polyethylene is powder, and the melt flow rate in the state is greater than 10 g / 10 min.

[0044] Preferably, the EVA is ethylene-vinyl acetate copolymer, the VA content is 18, the state of the ethylene-vinyl acetate copolymer is powder, and the melt flow rate in the state is greater than 50g / 10min.

[0045] Preferably, the conductive carbon black is superconductive carbon black.

[0046] Preferably, the compatibilizer is maleic anhydride grafted polyethylene, and the processing aid is fluoropolymer PPA.

[0047] The preparation method is the same as in Example 1.

Embodiment 3

[0049] An antistatic flame retardant masterbatch, mainly comprising the following components in parts by mass: 35 parts of LLDPE, 4 parts of EVA, 10 parts of POE, 6 parts of conductive carbon black, 4 parts of coated red phosphorus, processed The auxiliary agent is 2 parts, and the compatibilizer is 5 parts.

[0050] Preferably, the LLDPE is linear low density polyethylene, the state of the linear low density polyethylene is powder, and the melt flow rate in the state is greater than 10 g / 10 min.

[0051] Preferably, the EVA is ethylene-vinyl acetate copolymer, the VA content is equal to 18, the state of the ethylene-vinyl acetate copolymer is powder, and the melt flow rate in the state is greater than 50g / 10min.

[0052] Preferably, the conductive carbon black is superconductive carbon black.

[0053] Preferably, the compatibilizer is maleic anhydride grafted polyethylene, and the processing aid is fluoropolymer PPA.

[0054] The preparation method is the same as in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com