High molecular weight polyester based on biomass as monomer, preparation method and use thereof

A high molecular weight, biomass technology, applied in the field of two-step reaction of catalytic polycondensation, can solve the problems that are difficult to meet the material properties, mechanical properties, poor processability, low melting point, etc., to achieve improved mechanical properties, excellent mechanical properties and thermal properties, The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: 5.084g (20 mmol) of 2,5-dimethoxy dimethyl terephthalate, 1.862g (30 mmol) of 1,2-ethanediol and 0.017 g (0.1 mmol) of p-toluenesulfonic acid, under nitrogen atmosphere, under normal pressure, under the condition of magnetic stirring at 150°C, carry out the transesterification reaction for 3 hours to obtain the transesterified product; Under the condition of magnetic stirring at 250°C, the polycondensation reaction was carried out for 3 hours to obtain crude polyester; 50 mL of chloroform was added to the crude polyester, soaked for 3 hours and then filtered; the clear liquid was added dropwise to methanol to obtain a turbid system, which was centrifuged to obtain a precipitate. Filter, then wash with 10 mL of methanol, filter, and dry under vacuum at 60°C to obtain 5.022 g of polyester P 1 , and the yield was 89.59%.

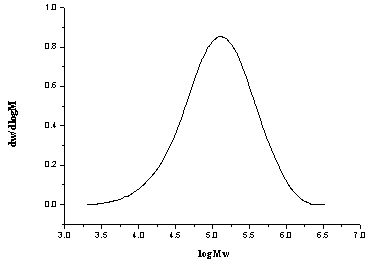

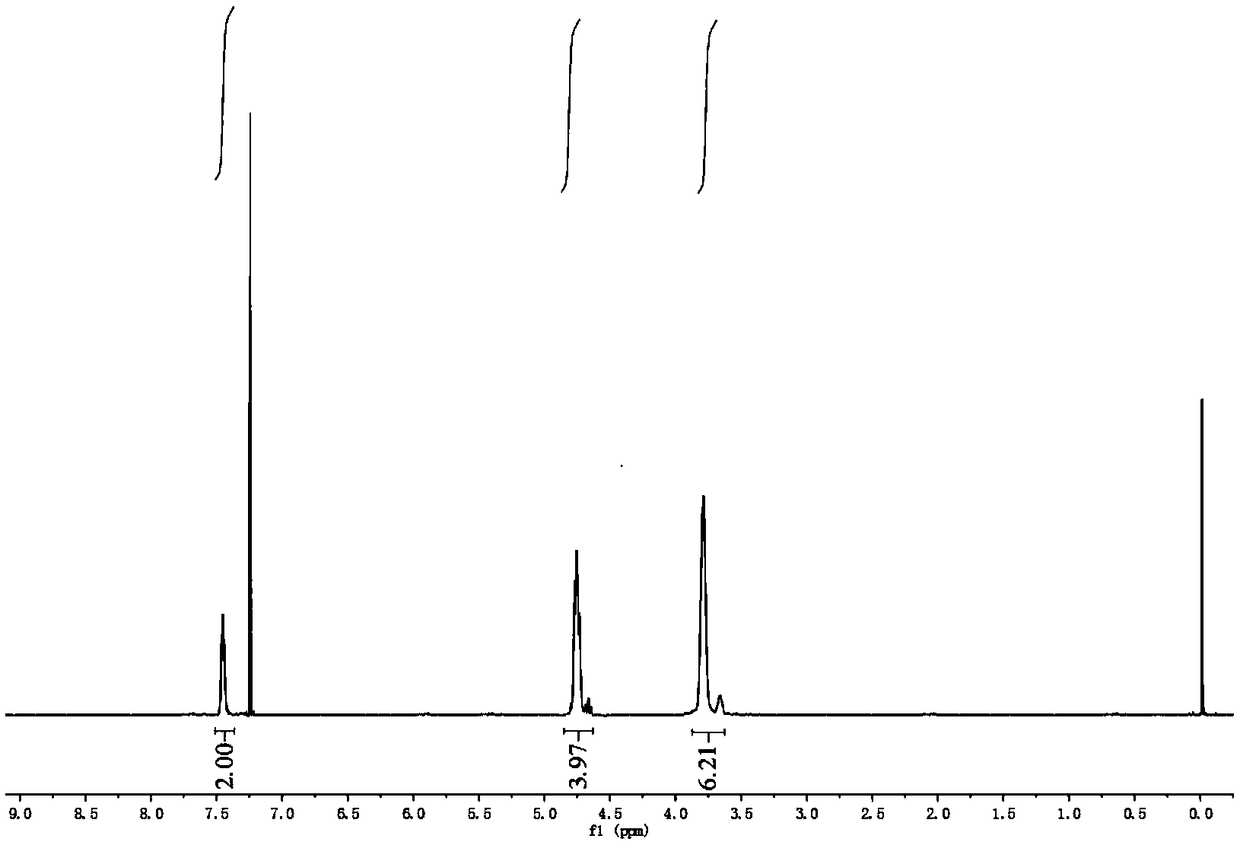

[0028] For determining the polyester P prepared in this embodiment 1 structure, molecular weight and thermal properties, adopt Bruker Avanc...

Embodiment 2

[0034] Example 2: 5.084g (20 mmol) of 2,5-dimethoxy dimethyl terephthalate, 4.387g (30 mmol) of 1,8-octanediol and 0.034 g (0.1 mmol) of tetrabutyl titanate was transesterified for 3 hours under nitrogen atmosphere, normal pressure, and magnetic stirring at 150°C to obtain the transesterified product; , under the condition of magnetic stirring at 250 ℃ for 3 hours, the polyester crude product was obtained; 50mL chloroform was added to the polyester crude product, soaked for 3 hours and then filtered; the clear liquid was added dropwise to methanol to obtain a turbid system, and a precipitate was obtained after centrifugation , filtered, and then washed with 10 mL of methanol, filtered, and vacuum-dried at 60 ° C to obtain 6.634 g of polyester P 2 , the yield is 91.01%.

Embodiment 3

[0035] Example 3: 5.084g (20 mmol) of 2,5-dimethoxy dimethyl terephthalate, 2.859g (28 mmol) of 1,3-cyclopentanediol and 0.03 g (0.1 mmol) of antimony trioxide was transesterified for 3 hours under a nitrogen atmosphere, normal pressure, and magnetic stirring at 150°C to obtain a transesterified product; , under the condition of magnetic stirring at 250 ℃ for 3 hours, the polyester crude product was obtained; 50mL chloroform was added to the polyester crude product, soaked for 3 hours and then filtered; the clear liquid was added dropwise to methanol to obtain a turbid system, and a precipitate was obtained after centrifugation , filtered, and then washed with 10 mL of methanol, filtered, and vacuum-dried at 60 ° C to obtain 5.699 g of polyester P 3 , and the yield was 88.96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com