Method for producing bran vinegar through solid state fermentation

A technology of solid-state fermentation and bran vinegar, which is applied in the field of fermentation, can solve the problems of maggot growth, achieve the effects of reducing production costs, fast start-up, and shortening the time of baking unstrained spirits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

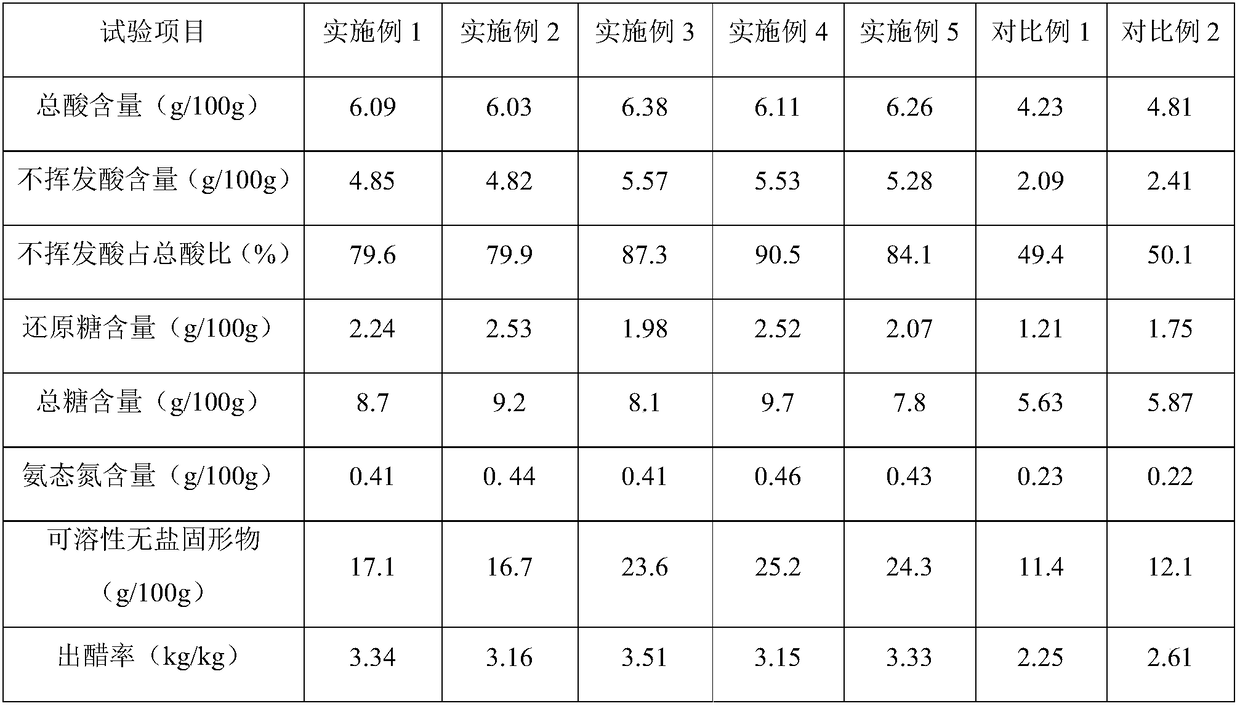

Examples

preparation example Construction

[0027] 1. Sample preparation

[0028] Sample preparation: Simulate the vinegar pouring operation, weigh 10g of vinegar unstrained spirits, put it into a beaker, add 60mL of 70°C pure water, soak for 40min, and stir once every 10min during this period; after soaking, transfer all the above materials into a 100mL capacity In the bottle, make up to volume with purified water. Finally, filter with filter paper to obtain the filtrate for subsequent use.

[0029] 2. Sample detection

[0030] Detection method of total acid content: refer to the national standard "GB18187-2000 National Standard of the People's Republic of China for Brewing Vinegar". Accurately draw 10.0mL of the sample, put it in a beaker and add 60mL of pure water, place the beaker on the tray of the acidity meter, start the magnetic stirrer, titrate to pH 8.2 with 0.05mol / L NaOH standard solution, and do a blank test at the same time;

[0031] Calculation formula for total acid content: X=60×C×(V 1 -V 2 )÷M;

...

Embodiment 1

[0058] Specific steps are as follows:

[0059] (1) Take 1100kg of glutinous rice, put it into a liquefaction tank after dry crushing, add 2600kg of tap water and 2.8kg of α-amylase, stir evenly, turn on the steam and heat to 90°C, keep warm and liquefy for 30 minutes; pump the liquefied rice milk into In the liquid fermentation tank, add 7400kg of tap water and cool down to 59°C, then add 4.5kg of glucoamylase, stir evenly, and keep warm at 59°C for 2.5h to obtain a saccharification solution; cool the saccharification solution to 30°C, add 0.5kg of Saccharomyces cerevisiae and Aroma yeast 2.5kg, stirred evenly, carried out liquid fermentation for 5 days to obtain vinegar distiller's mother;

[0060] Wherein, on the 1st day of the liquid fermentation, stir once in the morning and in the afternoon; on the 2d, stir once; on the 3rd to 5d until the end of the liquid fermentation, static fermentation;

[0061] (2) Import vinegar distiller's yeast into a solid-state fermentation ta...

Embodiment 2

[0065] Specific steps are as follows:

[0066] (1) Take 1200kg of glutinous rice, put it into a liquefaction tank after dry crushing, add 3000kg of tap water and 3.0kg of α-amylase, stir evenly, turn on the steam and heat to 90°C, keep warm and liquefy for 30 minutes; pump the liquefied rice milk into In the liquid fermentation tank, add 8000kg of tap water and cool down to 58°C, then add 5.5kg of glucoamylase, stir evenly, and keep warm at 58°C for 2.5h to obtain a saccharification solution; cool the saccharification solution to 28°C, add 0.8kg of Saccharomyces cerevisiae and 2.7kg of fragrant yeast, stirred evenly, carried out liquid fermentation for 5 days, and obtained vinegar distiller's mother;

[0067] Wherein, on the 1st day of the liquid fermentation, stir once in the morning and in the afternoon; on the 2d, stir once; on the 3rd to 5d until the end of the liquid fermentation, static fermentation;

[0068] (2) Import vinegar distiller's yeast into a solid-state ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com