Waterproof coating, and preparation method and application thereof

A technology for waterproof coatings and raw materials, applied in the field of chemical coatings, can solve the problems of increased cost input and labor input, easy melting and aging of waterproof coatings, poor adaptability of waterproof coatings, etc., and achieves moderate consistency, good spreadability, and texture. firming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

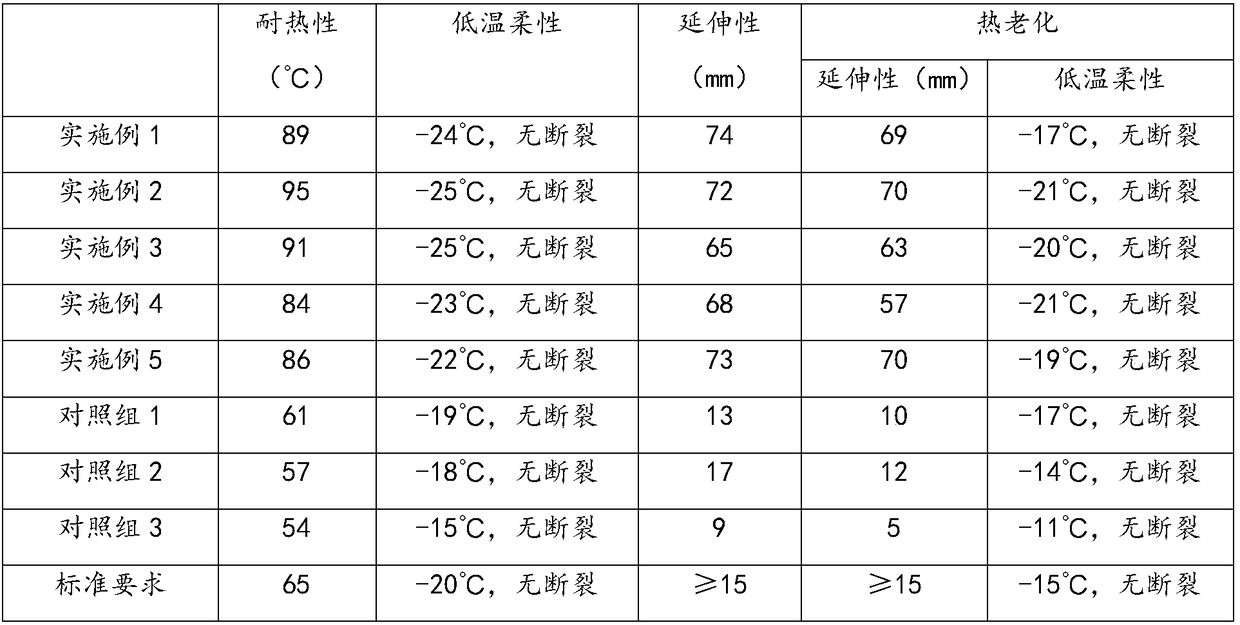

Examples

preparation example Construction

[0029] This embodiment also provides a preparation method for preparing the above-mentioned waterproof coating, which specifically includes the following steps, step 1, weighing the grease, thermoplastic elastomer, calcium powder, modifier and asphalt according to the above weight percentages for subsequent use;

[0030] Step 2, melt the asphalt weighed in step 1 at a temperature of 150-200°C, and add the oil, thermoplastic elastomer, calcium powder and modifier weighed in step 1 in sequence, and then keep stirring for 2-3 hours , and the mixture is circularly ground during the stirring process to obtain a molten liquid;

[0031] Step 3, cooling the molten liquid obtained in step 2 to 110-140°C, and then subpackaging to obtain the finished product.

[0032] This embodiment also provides an application of the above-mentioned waterproof coating in the preparation of a waterproof coiled material, which can make the waterproof coiled material also have a higher softening point, hi...

Embodiment 1

[0035] This embodiment provides a waterproof coating, which is composed of the following raw materials according to weight percentage, 18% of grease, 12% of thermoplastic elastomer, 12% of calcium powder, 1% of modifier and asphalt as the balance. Wherein, the grease is a mixture of aromatic oil, engine oil and base oil, and the ratio of aromatic oil, engine oil and base oil is 1:1:1; the asphalt is a mixture of 100# asphalt and 70# asphalt, wherein, 100# The amount ratio of # asphalt and 70# asphalt is 1:1 (mass ratio); the thermoplastic elastomer is SBS, SIS and SBR, and the amount ratio of SBS, SIS and SBR is 1:1:1 (mass ratio); The calcium powder is a mixture of light calcium powder and heavy calcium powder, and the dosage ratio of light calcium powder and heavy calcium powder is 1:1 (mass ratio); the modifier is asbestos fiber.

[0036] Its preparation method is as follows: Step 1, take grease, thermoplastic elastomer, calcium powder, modifier and asphalt according to the...

Embodiment 2

[0040] With embodiment 1, its difference is that described waterproof coating is made up of following raw material according to weight percentage, grease 22%, thermoplastic elastomer 17%, calcium powder 17%, modifier 3% and balance are asphalt. Wherein, the grease is a mixture of engine oil and base oil, and the amount ratio of engine oil and base oil is 1:1 (mass ratio); the asphalt is a mixture of 100# asphalt and 70# asphalt, wherein, 100# asphalt and 70# asphalt #The consumption ratio of pitch is 2:1 (mass ratio); The thermoplastic elastomer is SIS and SBR, and the consumption ratio of SIS and SBR is 1:1 (mass ratio); Described calcium powder is light calcium calcium powder and A mixture of heavy calcium calcium powder, and the dosage ratio of light calcium powder and heavy calcium powder is 2:1 (mass ratio); the modifier is asbestos fiber.

[0041] Its preparation method is as follows: Step 1, take grease, thermoplastic elastomer, calcium powder, modifier and asphalt acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com