High-temperature hydrothermally stable silicon-modified SCR catalyst and preparation method thereof

An SCR catalyst, high temperature hydrothermal technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced selectivity, inability to meet emission requirements, secondary air pollution, etc. Achieve the effect of improving hydrothermal stability, wide reaction temperature window and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

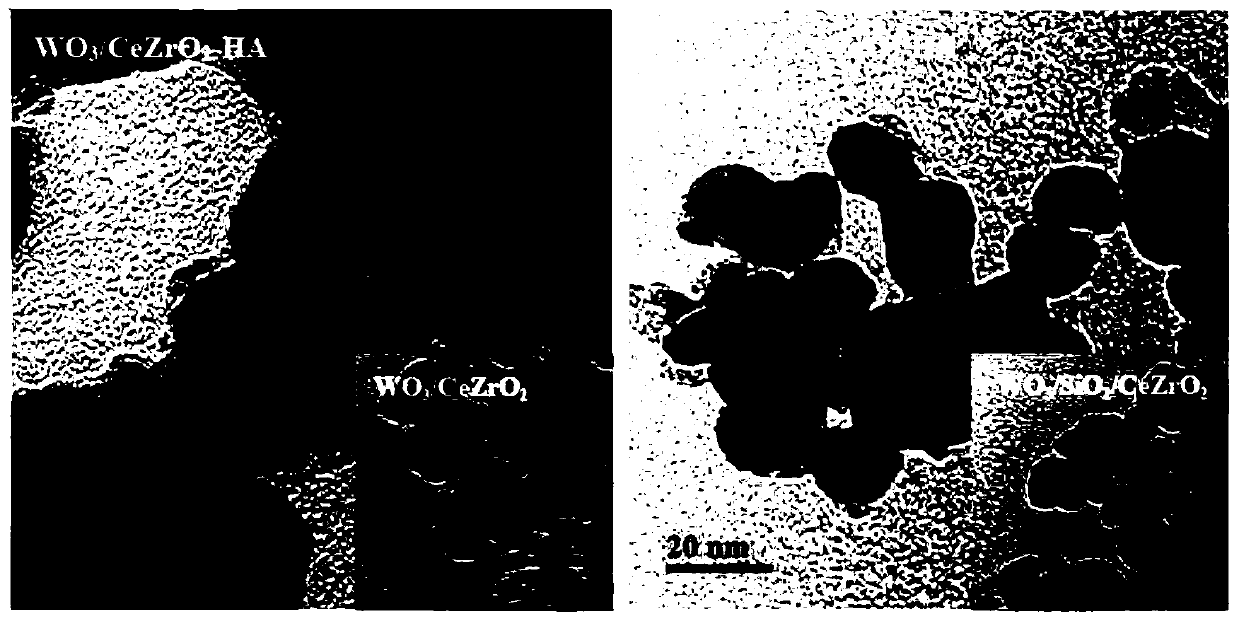

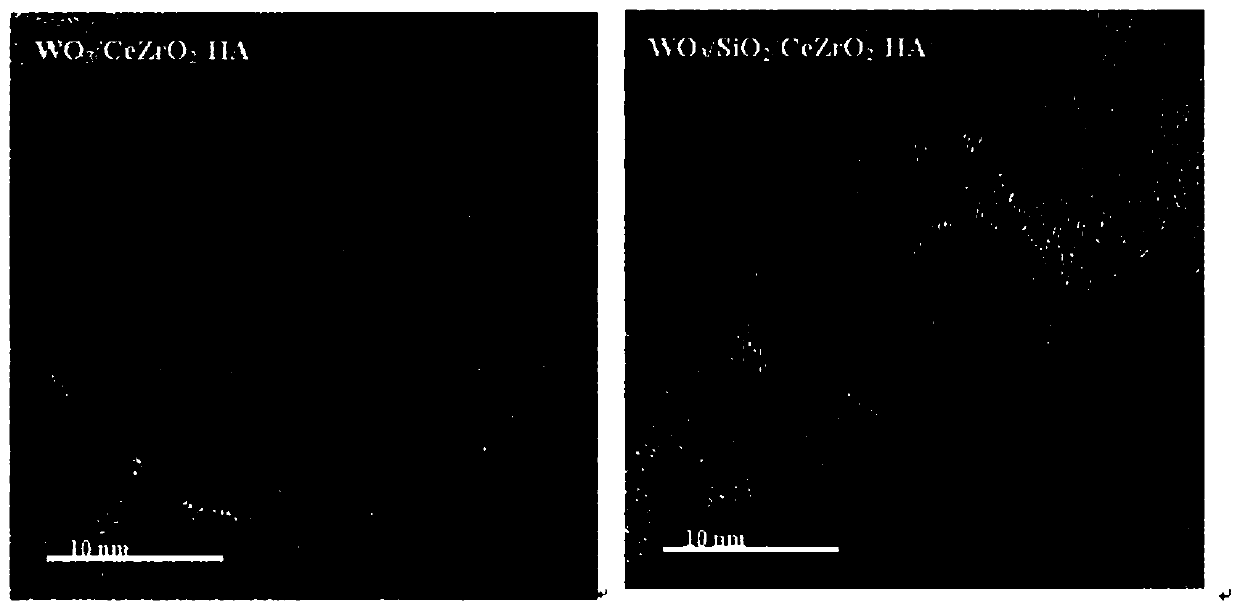

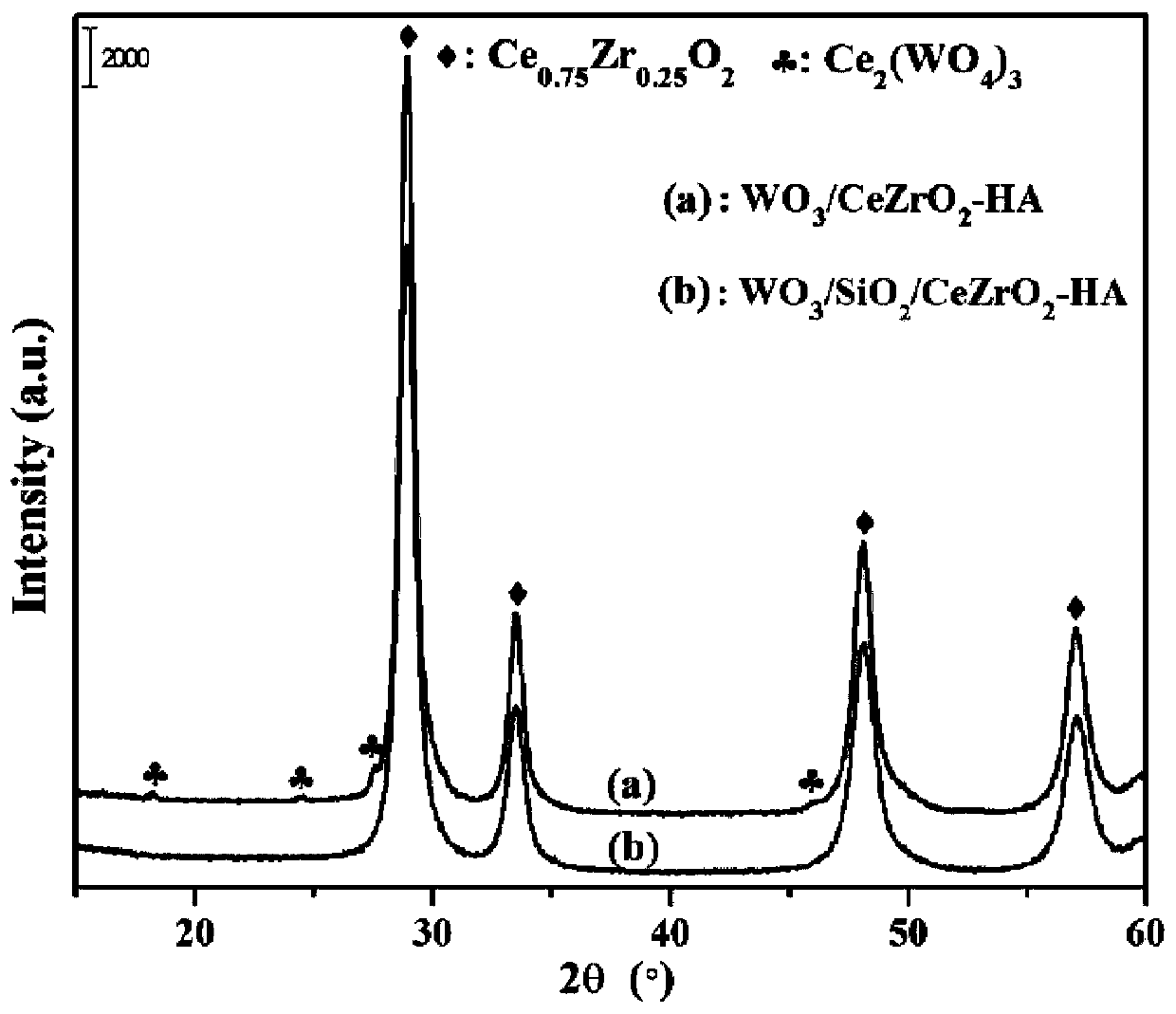

[0051] (1) Weigh 8 grams of cerium-zirconium powder CeZrO 2 Add the powder into 150 ml of deionized water, add 1.4 ml of tetraethyl orthosilicate under stirring at room temperature, continue stirring for 13 hours, and continue stirring for 3 hours after standing at room temperature for 12 hours; centrifuge the obtained suspension, wash the precipitate with deionized water, and remove the precipitate Put it in a water bath at 90°C, heat and stir continuously until the water evaporates to obtain a powder; put the powder in a 120°C oven and dry for 3 hours to obtain yellow SiO 2 / CeZrO 2 -1 powder.

[0052] (2) 1.04 grams of ammonium metatungstate was dissolved in 3.05 milliliters of deionized water to obtain ammonium metatungstate solution, and 8.47 grams of SiO 2 / CeZrO 2 Add -1 powder into the ammonium metatungstate solution, stir for 30 minutes, let it stand for 10 hours, put it in a water bath at 70°C, 80°C, and 90°C for 2 hours, and then bake it at 550°C for 3 hours in a...

Embodiment 2

[0056] (1) Weigh 8 grams of cerium-zirconium powder and add it to 150 ml of deionized water, add 3.4 ml of ethyl orthosilicate under magnetic stirring at room temperature, and continue stirring for 16 hours; centrifuge the obtained salt solution, wash the precipitate, and move the precipitate to 90 ° C In a water bath, heat and stir continuously until the water evaporates to obtain a powder; put the powder in an oven at 120°C for 3 hours to obtain yellow SiO 2 / CeZrO 2 -2 powder.

[0057] (2) 1.04 grams of ammonium metatungstate was dissolved in 3.05 milliliters of deionized water to obtain ammonium metatungstate solution, and 8.47 grams of SiO 2 / CeZrO 2 -2 powder was added to the ammonium metatungstate solution, stirred for 30 minutes, and after standing for 10 hours, put it into a water bath at 70°C, 80°C, and 90°C to dry for 2 hours respectively, and then roasted at 550°C for 3 hours in an air atmosphere to obtain WO 3 / SiO 2 / CeZrO 2 Catalyst powder, where WO 3 10%...

Embodiment 3

[0061] (1) Weigh 8 grams of cerium-zirconium powder and add it to 150 ml of deionized water, add 5.4 ml of ethyl orthosilicate under magnetic stirring at room temperature, and continue stirring for 16 hours; centrifuge the obtained salt solution, wash the precipitate, and move the precipitate to 90 ° C In a water bath, heat and stir continuously until the water evaporates to obtain a powder; put the powder in an oven at 120°C for 3 hours to obtain yellow SiO 2 / CeZrO 2 -3 powder.

[0062] (2) 1.04 grams of ammonium metatungstate was dissolved in 3.05 milliliters of deionized water to obtain ammonium metatungstate solution, and 8.47 grams of SiO 2 / CeZrO 2-3 powder was added to the ammonium metatungstate solution, stirred for 30 minutes, and after standing for 10 hours, put it into a water bath at 70°C, 80°C, and 90°C for 2 hours respectively, and then roasted at 550°C for 3 hours in an air atmosphere to obtain WO 3 / SiO 2 / CeZrO 2 Catalyst powder, where WO 3 10% by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com