A kind of preparation method of multilayer ceramic capacitor

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., can solve the problems of deterioration of consistency, incomplete deglue, and easy adhesion of ceramic bodies to each other, and achieve good consistency, density and Good dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

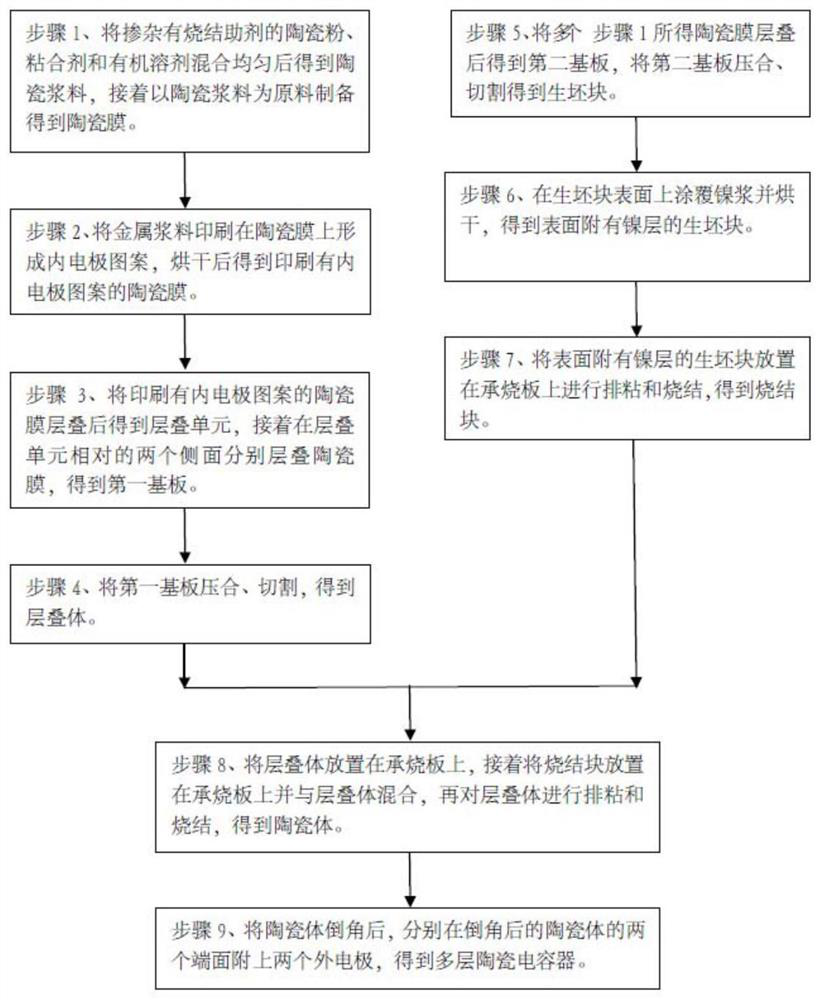

[0056] figure 1 It is a flow chart of the preparation method of the multilayer ceramic capacitor of the present invention, as an embodiment of the preparation method of the multilayer ceramic capacitor of the present invention, the preparation method of the multilayer ceramic capacitor of the present embodiment includes the following step:

[0057] Step 1. Mix the ceramic powder doped with the sintering aid, the binder and the organic solvent uniformly to obtain a ceramic slurry, and then use the ceramic slurry as a raw material to prepare a ceramic film.

[0058] In this embodiment, the operation of uniformly mixing the ceramic powder doped with sintering aid, the binder and the organic solvent is as follows: the ceramic powder doped with the sintering aid, the binder and the organic solvent are uniformly mixed by ball milling , The ball milling time is 10~16h.

[0059] The mass ratio of the ceramic powder doped with the sintering aid, the binder and the organic solvent in ...

Embodiment 2

[0104] The preparation method of the multilayer ceramic capacitor described in this embodiment is basically the same as that of Embodiment 1, except that:

[0105] Step 7, placing the green compact with the nickel layer on the surface on the setter for debonding and sintering to obtain a sintered compact.

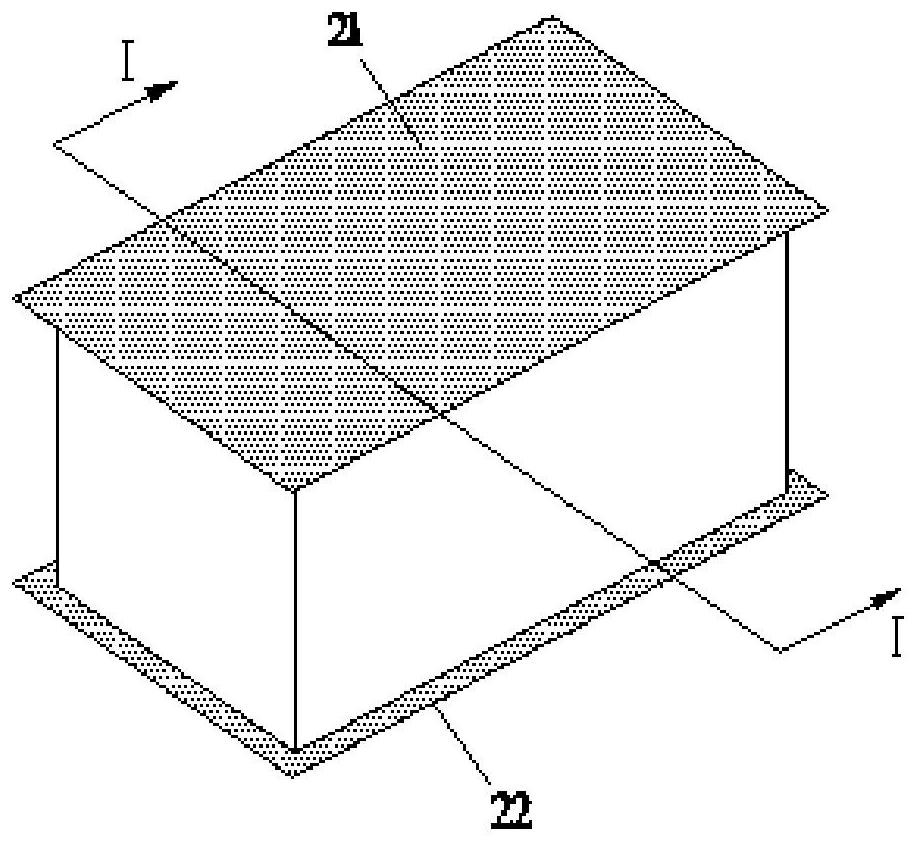

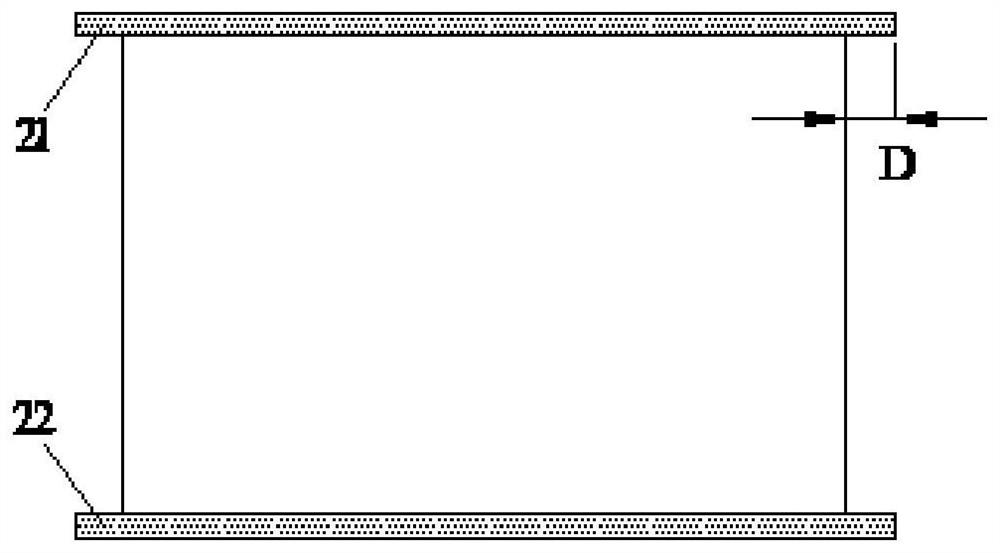

[0106] The sintered block obtained after sintering is as Figure 6 and Figure 7 As shown, the sintered block is rectangular. The sintered block is preferably a cube. The sintered block includes first and second sides opposite to each other, third and fourth sides opposite to each other, and first and second end faces opposite to each other.

[0107] Two nickel layers are attached to the sintered block in this embodiment, namely a first nickel layer 21 and a second nickel layer 22 . The first nickel layer 21 and the second nickel layer 22 surround and partially cover the first end surface, the second end surface, the first side surface and the second side surface of the...

Embodiment 3

[0114] The preparation method of the multilayer ceramic capacitor described in this embodiment is basically the same as that of Embodiment 1, except that:

[0115] Step 7, placing the green compact with the nickel layer on the surface on the setter for debonding and sintering to obtain a sintered compact.

[0116] The sintered block obtained after sintering is as Figure 8 As shown, the sintered block is rectangular. The sintered block is preferably a cube. The sintered block includes first and second sides opposite to each other, third and fourth sides opposite to each other, and first and second end faces opposite to each other. The six faces of the sintered block are all attached with the third nickel layer 23, and the six faces of the sintered block are respectively partially covered by at least one third nickel layer.

[0117] Step 8, placing the laminated body on the setter, then placing the agglomerate on the setter and mixing it with the laminated body, and then deb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com