Pure-carbon draw runner for subway and preparation method of pure-carbon draw runner

A technology of pure carbon and sliding strips, which is applied in the direction of railway vehicles, electric vehicles, power collectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

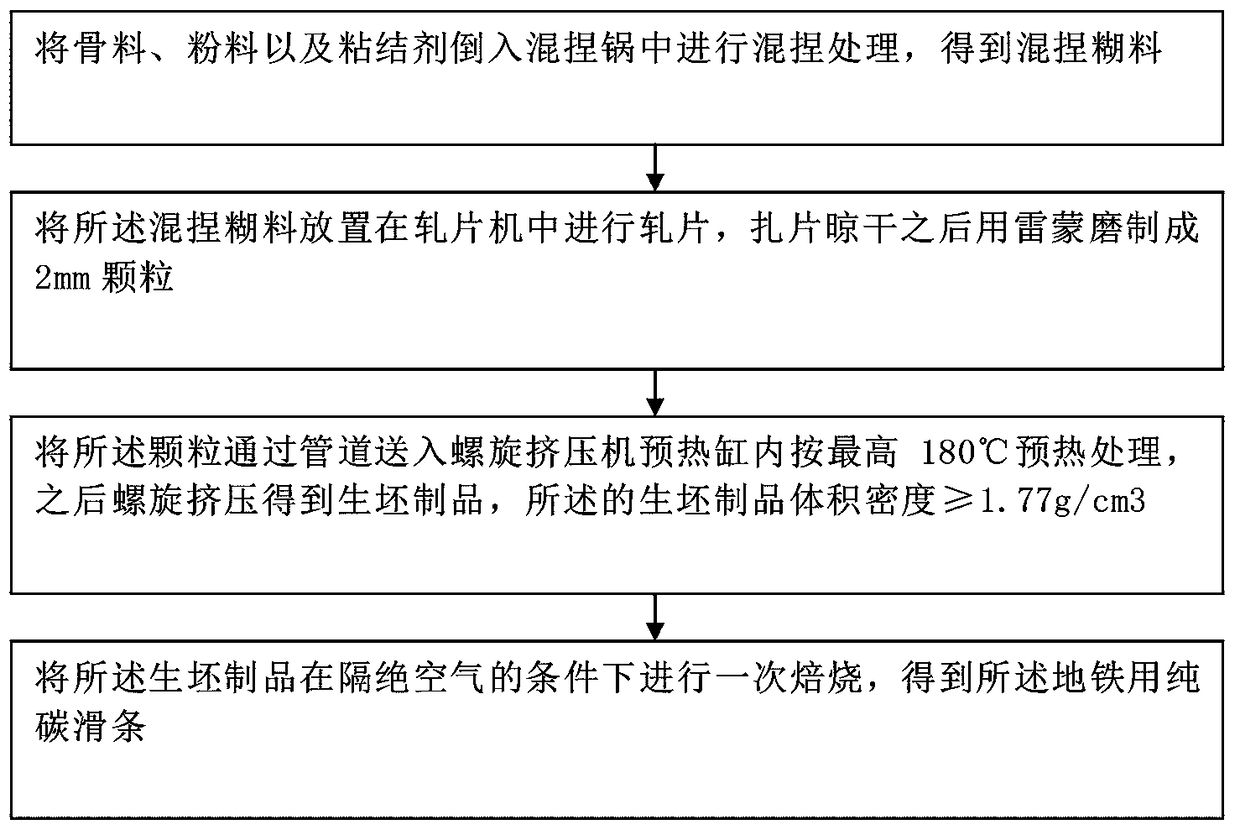

[0054] see figure 1 , a method for preparing a pure carbon slider for subways provided by an embodiment of the present invention, the method includes the following steps:

[0055] Pour the aggregate, powder and binder into the kneading pot for kneading treatment to obtain a kneaded paste;

[0056] The kneading paste is placed in a flaking machine for flaking, and after drying, the granules are made into 2mm particles with a Raymond mill;

[0057] Send the granules into the preheating cylinder of a screw extruder through a pipeline and preheat at a maximum temperature of 180°C, and then screw extrude to obtain a green product, and the volume density of the green product is ≥ 1.77g / cm3;

[0058] The green body product is fired once under the condition of air isolation to obtain the pure carbon slide bar for subway.

[0059] The preparation method of the pure carbon slider for the subway shown in this example produces the pantograph carbon slider material, which is a new type o...

Embodiment 2

[0060] Embodiment 2 is a kind of pure carbon slider for subway provided by the preferred embodiment of the present invention, and the method includes the following steps:

[0061] Pour the aggregate, powder and binder into the kneading pot for kneading treatment to obtain a kneaded paste;

[0062] The kneading paste is placed in a flaking machine for flaking, and after drying, the granules are made into 2mm particles with a Raymond mill;

[0063] Send the granules into the preheating cylinder of a screw extruder through a pipeline and preheat at a maximum temperature of 180°C, and then screw extrude to obtain a green product, and the volume density of the green product is ≥ 1.77g / cm3;

[0064] The green body product is fired once under the condition of air isolation to obtain the pure carbon slide bar for subway.

[0065] Wherein, the said pouring the aggregate, powder and binder into the kneading pot for kneading treatment includes: putting the aggregate and powder into the ...

Embodiment 3

[0067] Embodiment 3 is a kind of pure carbon sliding bar for subway provided by the preferred embodiment of the present invention. The method includes the following steps:

[0068] Pour the aggregate, powder and binder into the kneading pot for kneading treatment to obtain a kneaded paste;

[0069] The kneading paste is placed in a flaking machine for flaking, and after drying, the granules are made into 2mm particles with a Raymond mill;

[0070] Send the granules into the preheating cylinder of a screw extruder through a pipeline and preheat at a maximum temperature of 180°C, and then screw extrude to obtain a green product, and the volume density of the green product is ≥ 1.77g / cm3;

[0071] The green body product is fired once under the condition of air isolation to obtain the pure carbon slide bar for subway.

[0072] Wherein, the temperature of the green product is raised from 150°C to 550°C at a heating rate of 1.1-2.1°C / h;

[0073] Raise the temperature from 550°C to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com