In-mold integral-forming image and text transfer printing method for silicone button

A silicone and key technology, applied in the directions of copying/marking methods, printing, printing devices, etc., can solve the problems of poor size control, many production personnel, long production cycle, etc., to save production cycle, production cost, equipment investment, etc. The effect of many, low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

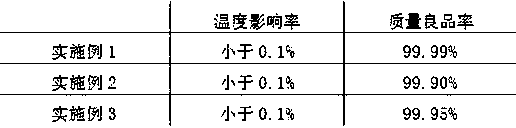

Embodiment 1

[0025] A method for transferring pictures and texts into a silicone keypad integrally formed in a mold, comprising the following steps:

[0026] Step 1) Back coating of PET sheet: select DD10-0.18MM type PET sheet back and spray it with silicone oil solvent, the coating thickness is 1um±0.05um; then coating and baking, the speed of coating and baking is 50m / min , coating baking temperature 115° / 15min;

[0027] Step 2) PET front coating: After step 1), apply a layer of paraffin wax on the PET front, the coating thickness is 1um±0.05um; then coating and baking, the speed of coating and baking is 40m / min, the coating and baking temperature 95° / 15min;

[0028] Step 3) Coating on paraffin: Spray the TPU resin mixture on the paraffin, the coating thickness is 4um±0.05um, then coating and baking, the speed of coating and baking is 30m / min, the coating and baking temperature 115° / 15min;

[0029] Step 4) Color printing and printing graphics: use 4+1 Heidelberg machine and screen pri...

Embodiment 2

[0040] A method for transferring pictures and texts into a silicone keypad integrally formed in a mold, comprising the following steps:

[0041] Step 1) Back coating of PET sheet: select DD10-0.18MM type PET sheet back and spray it with silicone oil solvent, the coating thickness is 1um±0.05um; then coating and baking, the speed of coating and baking is 50m / min , coating baking temperature 120° / 15min;

[0042] Step 2) PET front coating: After step 1), apply a layer of paraffin wax on the PET front, the coating thickness is 1um±0.05um; then coating and baking, the speed of coating and baking is 40m / min, the coating and baking temperature 100° / 15min;

[0043] Step 3) Coating on paraffin: Spray the TPU resin mixture on the paraffin, the coating thickness is 4um±0.05um, then coating and baking, the speed of coating and baking is 30m / min, the coating and baking temperature 120° / 15min;

[0044] Step 4) Color printing and printing graphics: use 4+1 Heidelberg machine and screen pr...

Embodiment 3

[0055] A method for transferring pictures and texts into a silicone keypad integrally formed in a mold, comprising the following steps:

[0056] Step 1) Back coating of PET sheet: select DD10-0.18MM type PET sheet back and spray it with silicone oil solvent, the coating thickness is 1um±0.05um; then coating and baking, the speed of coating and baking is 50m / min , coating baking temperature 125° / 15min;

[0057] Step 2) PET front coating: After step 1), apply a layer of paraffin wax on the PET front, the coating thickness is 1um±0.05um; then coating and baking, the speed of coating and baking is 40m / min, the coating and baking temperature 105° / 15min;

[0058] Step 3) Coating on paraffin: Spray the TPU resin mixture on the paraffin, the coating thickness is 4um±0.05um, then coating and baking, the speed of coating and baking is 30m / min, the coating and baking temperature 125° / 15min;

[0059] Step 4) Color printing and printing graphics: use 4+1 Heidelberg machine and screen prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com