ETPU (expanded thermoplastic polyurethane) prefabricated type sport floor and method for preparing same

A prefabricated and moving technology, applied to roads, pavements, roads, etc., can solve the problems of difficult physical performance, poor protection of users, long construction period, etc., to eliminate harmful substances and pungent odors, and prepare And the forming process is green and environmentally friendly, saving production costs and cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1E

[0025] Example 1 ETPU prefabricated sports floor

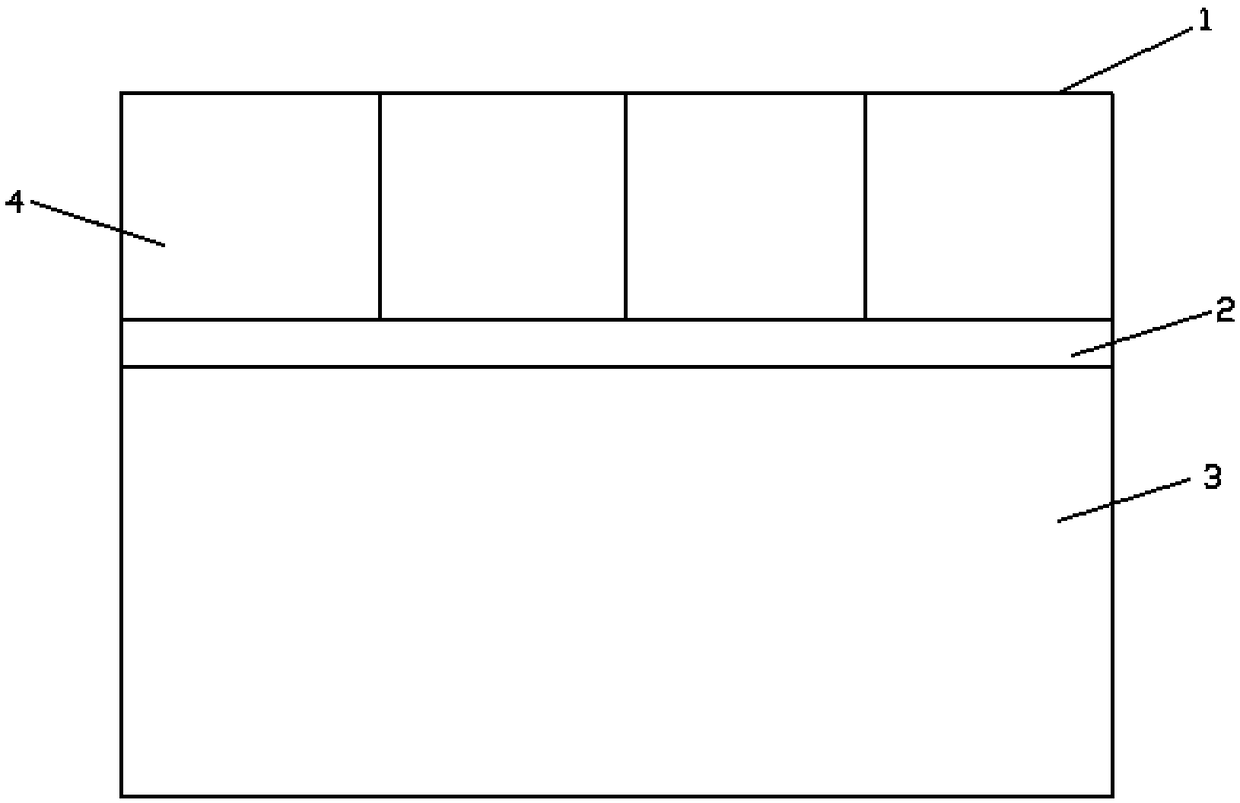

[0026] Such as figure 1 The ETPU prefabricated sports floor shown is mainly composed of a surface layer 1, a glue layer 2 and a base layer 3 arranged in sequence from top to bottom. The surface layer 1 is an ETPU prefabricated block layer formed by splicing a plurality of ETPU prefabricated blocks 4, and the thickness of the surface layer 1 is 8-25mm. The base layer 3 is a concrete or asphalt poured ground. The glue layer 2 is paved by a one-component polyurethane adhesive, and other glues in the field can also be used for paving the surface layer 1 firmly on the base layer 3 . The ETPU prefabricated block 4 is a rectangle, and can also be other shapes convenient for splicing, such as hexagons.

Embodiment 2

[0027] Example 2 Preparation of ETPU prefabricated sports floor

Embodiment 1

[0028] The ETPU prefabricated sports floor of embodiment 1 is obtained according to the following steps:

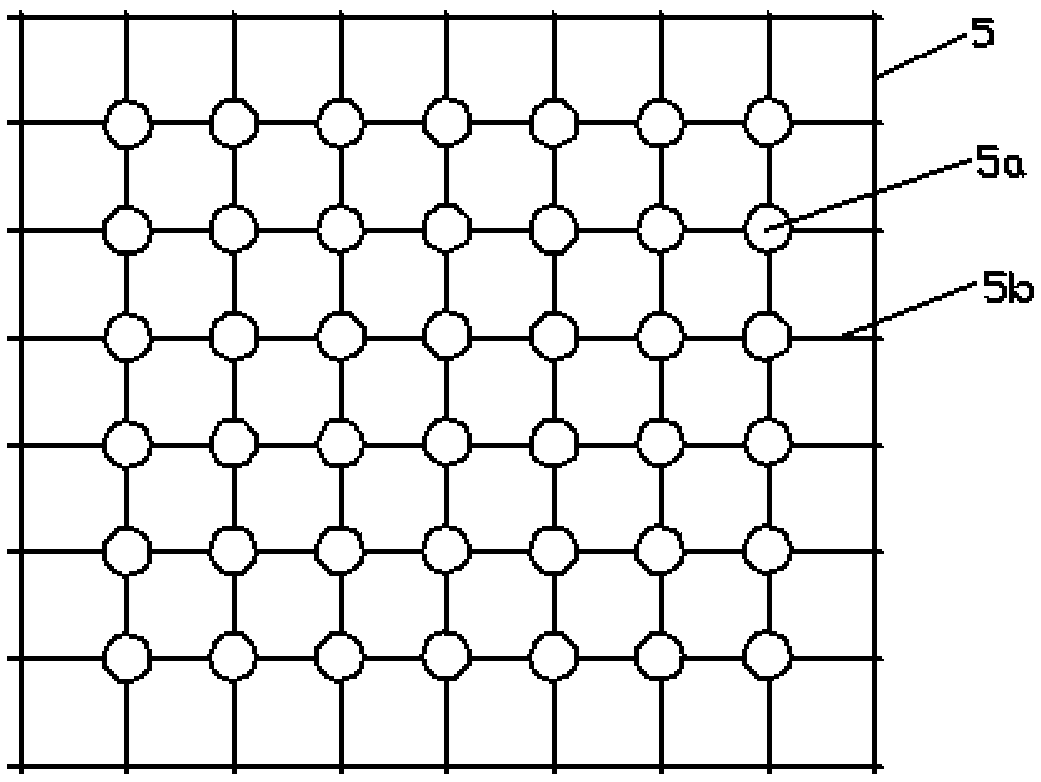

[0029] 1) Preparation of TPU shaped plate 5: TPU granules are made into TPU shaped plate through injection molding process. Such as figure 2 As shown, the TPU shaping board 5 is a grid plate of a rectangular or other shape that is convenient for splicing multiple pieces. The grid can be rectangular, honeycomb, circular, polygonal or other shapes. Currently, there are various molds available on the market, which can produce There are many kinds of stereotyped plates with different grid shapes. Several support columns 5a are arranged on the lower surface of the TPU shaped plate 5, and the support columns 5a may be in the shape of a cylinder, a square column, a polygonal column, a trapezoidal column, and the like. The support column structure on the TPU shaped board is extremely stable and resilient, which can perfectly meet the user's sports experience. The lower surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com