Composite film for efficiently and rapidly capturing heavy metal in complex system and application method thereof

A composite membrane and heavy metal technology, applied in the field of composite membrane, can solve the problems of poor load bearing capacity, poor treatment effect, heavy secondary pollution, etc., achieve the effect of reducing heavy metal concentration, easy application and operation, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

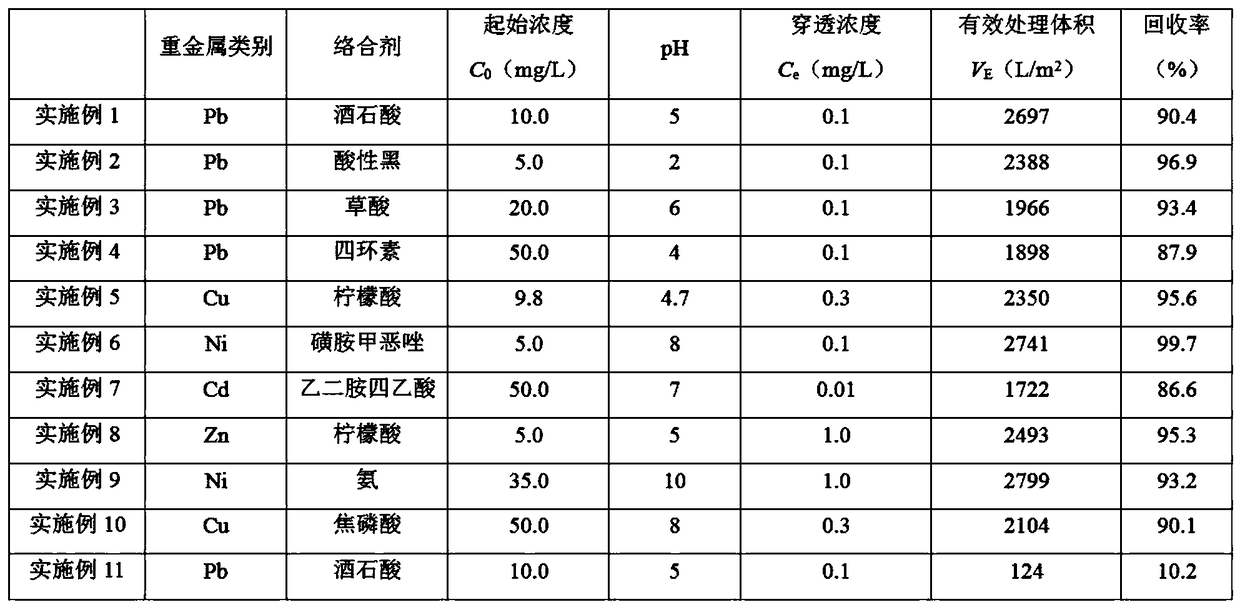

Examples

Embodiment 1

[0027] A kind of composite film and its application method for efficient and fast trapping of heavy metals in a complex system, the steps of which are:

[0028] (1) the composite waste water (initial concentration of lead is 10mg / L, and the initial concentration of tartaric acid is 10mg / L) of the composite wastewater of lead to be treated and tartaric acid is adjusted to 5, then pumps into the filter system of filling composite membrane, control The adsorption temperature is 30°C, and the effluent flow rate is 15.0L m -2 h -1 , until the adsorption breaks through.

[0029] (2) After the adsorption is saturated, pump hydrochloric acid with a mass fraction of 10% into the filter system in step (1) for regeneration, control the regeneration temperature to 25°C, and the outlet water flow rate to 30.0L m -2 h -1 , and the regenerated composite membrane was washed to neutral with water to obtain a regenerated composite membrane.

[0030] Composite membrane preparation method in ...

Embodiment 2

[0034] With embodiment 1, difference is: the initial concentration of lead is 5mg / L in the step (1), and acid black replaces tartaric acid, and initial concentration is 20mg / L, and pretreatment process regulates pH value to be 2, and control adsorption The temperature is 45°C, and the outlet water flow rate is 20.0L m -2 h -1 n, step (2) is regenerated with dilute nitric acid with a mass fraction of 5%, the regeneration temperature is 35°C, and the flow rate is 10.0L m -2 h -1 .

Embodiment 3

[0036] With embodiment 1, difference is: the initial concentration of lead is 20mg / L in the step (1), and oxalic acid replaces tartaric acid, and initial concentration is 2mg / L, and the pretreatment process adjustment pH value is 6, and control adsorption temperature at 5°C, the outlet water flow rate is 0.1L m -2 h -1 , the regeneration process of step (2) uses dilute sulfuric acid with a mass fraction of 2% for regeneration, the regeneration temperature is 50°C, and the flow rate is 0.1L m -2 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com