Biodegradable hard tissue repair composite scaffold prepared by 3D printing technology and preparation method thereof

A composite scaffold and 3D printing technology, which is applied in the field of biomedical materials, can solve problems such as unsatisfactory bone repair effects, and achieve the effects of facilitating promotion and application, increasing the degree of dispersion, and regularizing the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

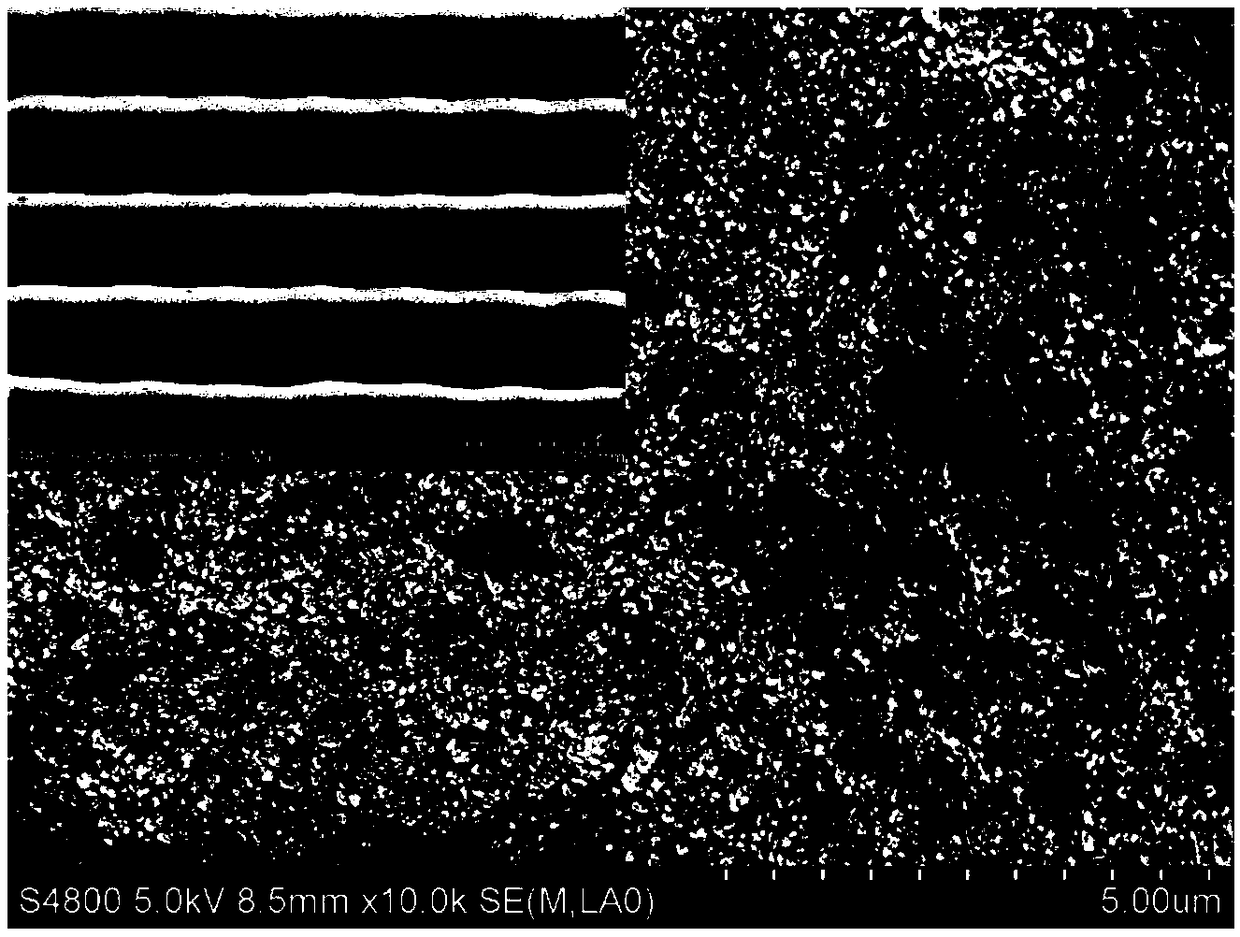

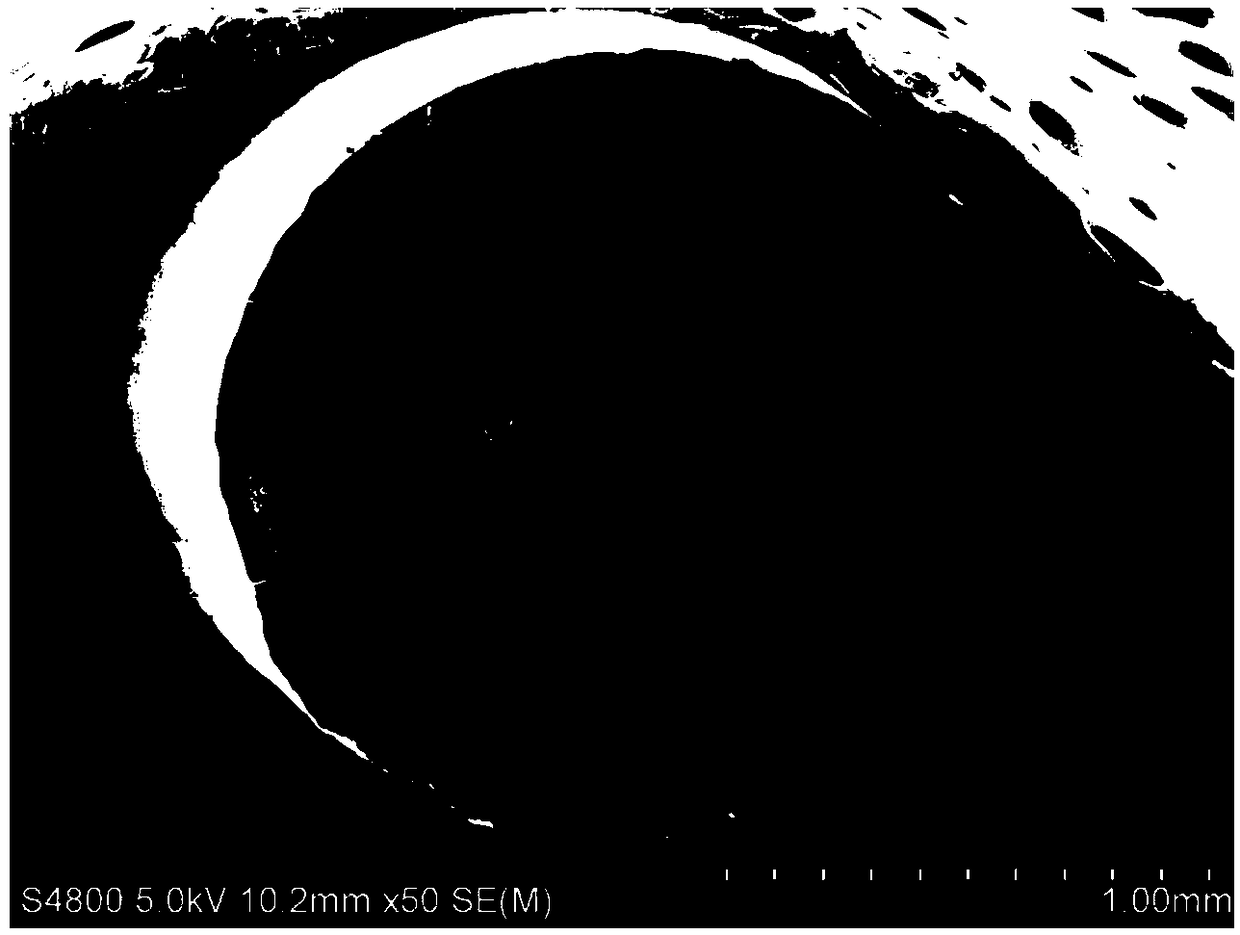

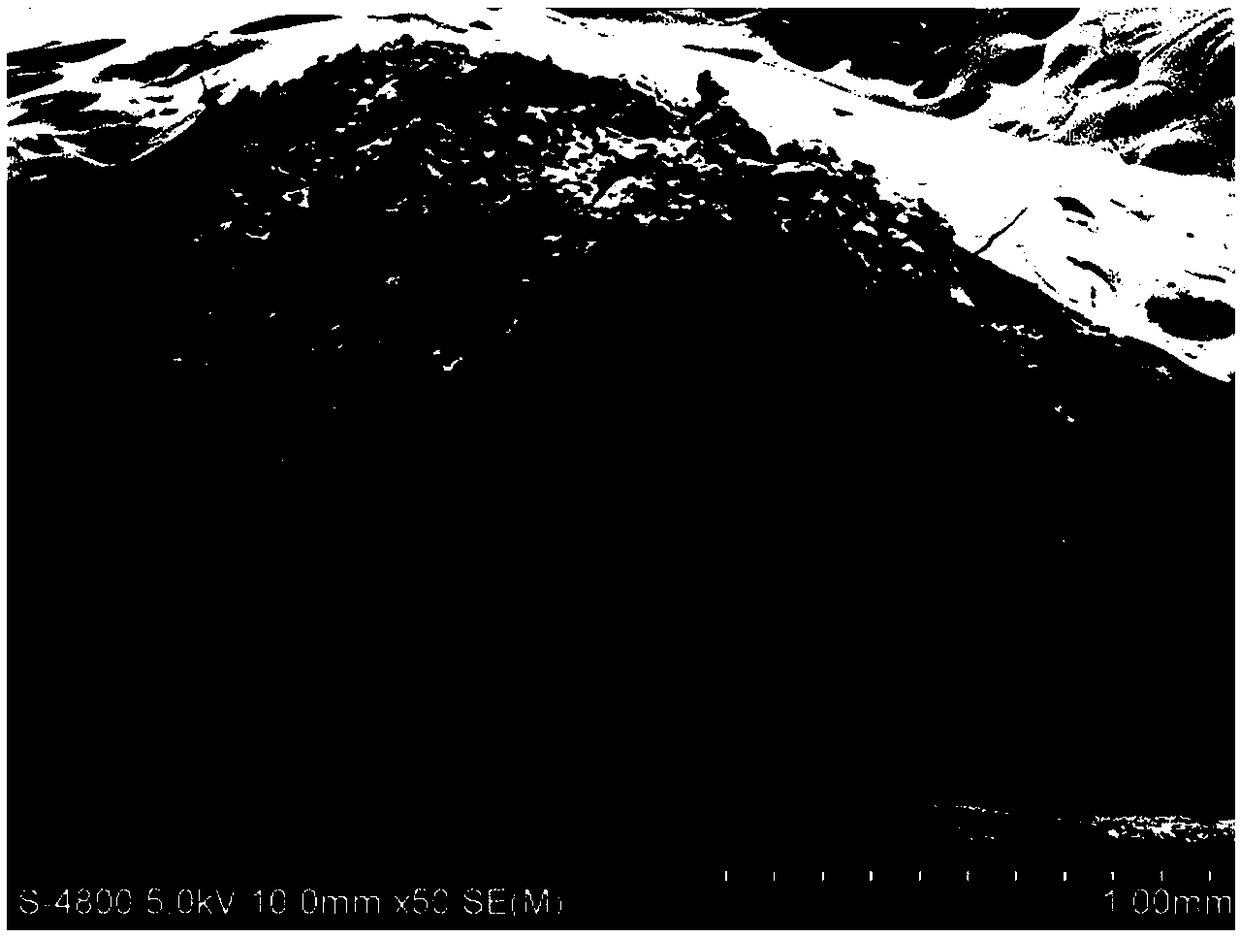

Embodiment 1

[0056] A composite scaffold with a mass ratio of polylactic acid / hydroxyapatite of 6 / 4 was prepared. 1. According to the conversion of mass fraction, centrifuge a certain amount of hydroxyapatite suspension to remove the supernatant, add an appropriate amount of acetone to ultrasonically stir uniformly, centrifuge again to remove the supernatant, this process is repeated three times. The washed hydroxyapatite is added to the acetone solution so that the hydroxyapatite accounts for 10% of the total suspension mass fraction. Then, 0.2% of the total mass fraction of the composite material was added with a silane coupling agent to the acetone solution of hydroxyapatite and stirred for 12 hours. 2. According to the conversion of mass fraction, add a certain amount of polylactic acid to methylene chloride to fully dissolve it, in which the polymer accounts for 10% of the total mass of the solution system, and the polymer solution is obtained as a spare. 3. After mixing the solutions...

Embodiment 2

[0058] A composite scaffold with a mass ratio of polylactic acid / tricalcium phosphate of 6 / 4 was prepared. 1. According to the conversion of mass fraction, prepare a 10% tricalcium phosphate acetone suspension, and then add 0.2% of the total mass fraction of the composite silane coupling agent to the tricalcium phosphate acetone solution for 12 hours. 2. According to the conversion of mass fraction, add a certain amount of polylactic acid to methylene chloride to fully dissolve it, in which the polymer accounts for 10% of the total mass of the solution system, and the polymer solution is obtained as a spare. 3. After mixing the solutions obtained in 1 and 2, remove the solvent to the composite material block. 4. The material block is mechanically crushed, and then the standard wire is extruded. 5. Use an FDM printer to print out the target scaffold (complex structures such as human bone models). In this embodiment, the biodegradable polymer is polylactic acid, and the inorgan...

Embodiment 3

[0060] A composite scaffold with a mass ratio of polylactic acid / biphasic calcium phosphate (BCP) of 6 / 4 was prepared. 1. According to the conversion of mass fraction, prepare a 10% diphasic calcium phosphate acetone suspension, and then add the silane coupling agent to the diphasic calcium phosphate acetone solution for 12 hours. 2. According to the mass fraction conversion, add a certain amount of polylactic acid to the methylene chloride to fully dissolve it, and obtain a polymer solution for use. 3. After mixing the solutions obtained in 1 and 2, remove the solvent to the composite material block. 4. The material block is mechanically crushed, and then the standard wire is extruded. 5. Use an FDM printer to print out the target scaffold (complex structures such as human bone models). In this embodiment, the biodegradable polymer is polylactic acid, and the inorganic active ingredient is biphasic calcium phosphate. Biphasic calcium phosphate is a mixture of hydroxyapatite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com