Method for treating serpentine by utilizing H2SO4-fluorination combination method

A combined treatment and serpentine technology, applied in the direction of silicon oxide, silicon dioxide, process efficiency improvement, etc., can solve the problem of low leaching rate and achieve the effect of improving the leaching rate of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

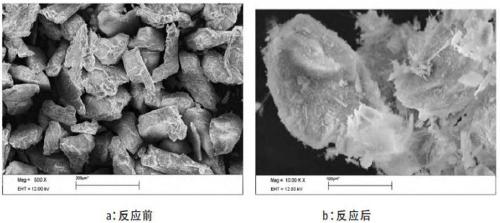

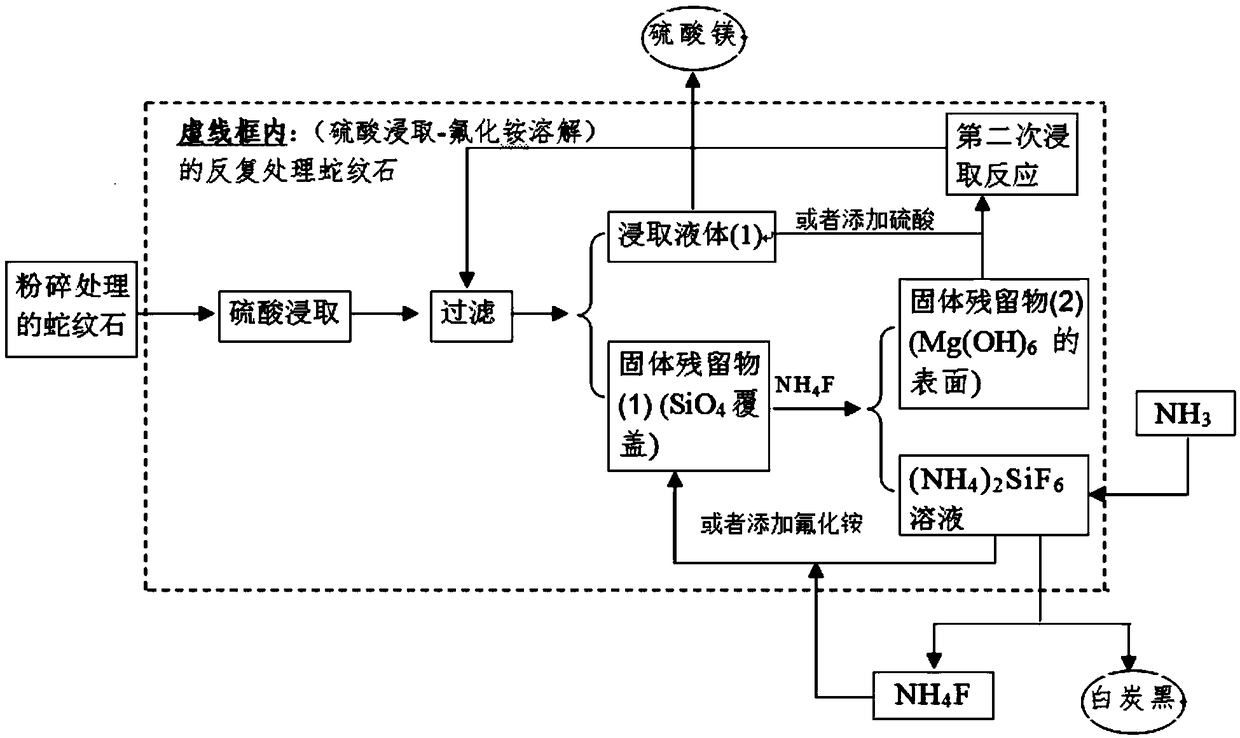

[0037] In this example, see figure 2 , a method using H 2 SO 4 -The method for the combined treatment of serpentine by fluorination, comprising the steps of:

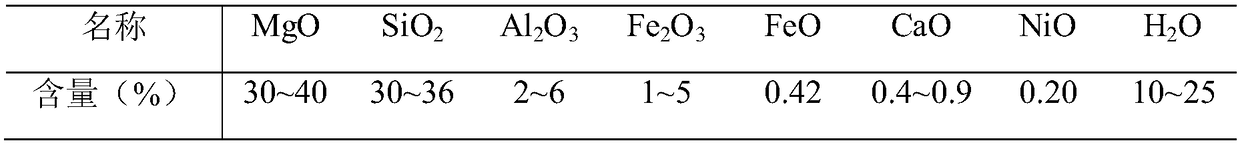

[0038] a. leaching the pretreated serpentine with sulfuric acid, then filtering to realize solid-liquid separation, and collecting the solid residue retained after filtering to obtain SiO-containing 2 The serpentine residue; The pretreatment serpentine condition in said step a is:

[0039] After the serpentine is crushed, ball milling is carried out, and all particle sizes are sieved through a 200-mesh sieve to obtain serpentine powder, and then the serpentine powder is calcined at 700°C for 15 minutes. Obtain the calcined pre-activated serpentine powder;

[0040] The leaching conditions of pretreatment serpentine and sulfuric acid:

[0041] The solid-liquid mass and volume ratio of pretreated serpentine and sulfuric acid is 0.1:10 (g / mL), the stirring speed of the pretreated serpentine and sulfuric acid mixture i...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, especially in that:

[0058] In this example, a H 2 SO 4-The method for the combined treatment of serpentine by fluorination, comprising the steps of:

[0059] a. leaching the pretreated serpentine with sulfuric acid, then filtering to realize solid-liquid separation, and collecting the solid residue retained after filtering to obtain SiO-containing 2 The serpentine residue; The pretreatment serpentine condition in said step a is:

[0060] After the serpentine is crushed, ball milling is carried out, and all particle sizes are sieved through a 100-mesh sieve to obtain serpentine powder, and then the serpentine powder is calcined at a temperature of 500°C, and the calcining time is 180 minutes. Obtain the calcined pre-activated serpentine powder;

[0061] The leaching conditions of pretreatment serpentine and sulfuric acid:

[0062] The solid-liquid mass and volume ratio of the pretreated serpentine and sulfuric...

Embodiment 3

[0069] This embodiment is basically the same as the previous embodiment, and the special features are:

[0070] In this example, a H 2 SO 4 -The method for the combined treatment of serpentine by fluorination, comprising the steps of:

[0071] a. leaching the pretreated serpentine with sulfuric acid, then filtering to realize solid-liquid separation, and collecting the solid residue retained after filtering to obtain SiO-containing 2 The serpentine residue; The pretreatment serpentine condition in said step a is:

[0072] After the serpentine is crushed, ball milling is carried out, and the size of the particles is all passed through a 200-mesh sieve to obtain the serpentine powder;

[0073] The leaching conditions of pretreatment serpentine and sulfuric acid:

[0074] The solid-liquid mass and volume ratio of pretreated serpentine and sulfuric acid is 0.1:10 (g / mL), the stirring speed of the pretreated serpentine and sulfuric acid mixture is 500rpm, the temperature is 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com