A kind of high-damping asphalt material for system vibration reduction and preparation method thereof

A technology for system vibration reduction and asphalt materials, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of small deformation of asphalt, large influence of time and temperature effects, and failure to achieve vibration reduction effects, etc., to achieve high adhesion, Good fluidity, vibration suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

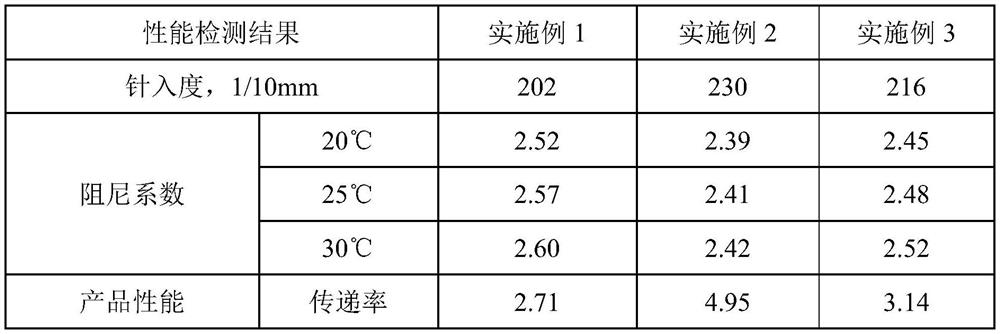

Embodiment 1

[0029] A high-damping asphalt material for system vibration reduction of the present invention, comprising the following components in parts by mass: 100 parts of 70# asphalt / 130# asphalt, 20 parts of liquid EPDM rubber, 10 parts of hydrogenated rosin, Guma Long resin 5 parts, mica powder / graphite 20 parts. The preparation method of the high-damping asphalt material for system vibration-damping comprises the following steps:

[0030] (1) Put the bitumen in an oven at 80°C to soften for 1.5 hours;

[0031] (2) Put the softened asphalt in the step (1) into one end of the large cone of the mill while it is hot, add fillers, resins and other powders in turn, control the temperature of the rollers of the mill at about 50°C, and constantly turn left and right Refining and thinning until the powder and asphalt are evenly dispersed to obtain a mixed material;

[0032] (3) add liquid rubber and solid plasticizer to the mixed material obtained after said step (2), in the process of ad...

Embodiment 2

[0034] A high-damping asphalt material for system vibration reduction of the present invention, comprising the following components in parts by mass: 100 parts of 90# asphalt, 40 parts of liquid silica gel, 10 parts of black ointment, 20 parts of super tackifying resin, Qianwei Powder 20 parts. The preparation method of the high-damping asphalt material for system vibration-damping comprises the following steps:

[0035] (1) Put the asphalt in an oven at 90°C to soften for 1 hour;

[0036] (2) Put the softened asphalt in the step (1) into one end of the large cone of the mill while it is hot, add fillers, resins and other powders in turn, control the temperature of the rollers of the mill at about 50°C, and constantly turn left and right Refining and thinning until the powder and asphalt are evenly dispersed to obtain a mixed material;

[0037](3) Add liquid rubber and solid plasticizer to the mixed material obtained after said step (2), in the process of adding, the viscosi...

Embodiment 3

[0039] A high-damping asphalt material for system vibration reduction of the present invention, comprising the following components in parts by mass: 100 parts of 70# asphalt / 110# asphalt, 30 parts of liquid nitrile rubber, 10 parts of black ointment, super thickening Resin / petroleum resin 20 parts, carbon black / Qianwei powder 30 parts. The preparation method of the high-damping asphalt material for system vibration-damping comprises the following steps:

[0040] (1) Put the asphalt in an oven at 90°C to soften for 1 hour;

[0041] (2) Put the softened asphalt in the step (1) into one end of the large cone of the mill while it is hot, add fillers, resins and other powders in turn, control the temperature of the rollers of the mill at about 50°C, and constantly turn left and right Refining and thinning until the powder and asphalt are evenly dispersed to obtain a mixed material;

[0042] (3) Add liquid rubber and solid plasticizer to the mixed material obtained after said ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com