Method for achieving azo polymer film surface patterning through laser

A polymer film and surface patterning technology, applied in the direction of coating, etc., can solve the problems of high energy consumption and large pollution, achieve good repeatability, and avoid the effect of complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of method that realizes the surface patterning of azo polymer film by laser, comprises the following steps:

[0021] Step 1: After mixing the PDMS prepolymer and the crosslinking agent according to the mass ratio of 30:1, pour it into a centrifuge tube, and stir it with a glass rod to form a uniform mixture;

[0022] Step 2: vacuum degas the mixture of PDMS prepolymer and cross-linking agent for 1 hour, then pour it into a square petri dish, and make it evenly distributed in the petri dish;

[0023] Step 3: Vacuum degas the mixture of prepolymer and crosslinking agent poured into the petri dish for 30 minutes, then put it into an oven, and heat and cure at 70 degrees Celsius for 4 hours;

[0024] Step 4: First, ultrasonically clean the glass slides successively with distilled water and absolute ethanol, then place them in a mixed solution of hydrogen peroxide / ammonia / deionized water (volume ratio 1:1:5) and heat at 70°C for 10 minutes, and finally u...

Embodiment 2

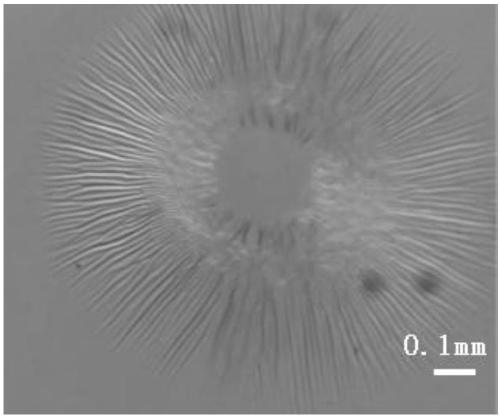

[0028] Embodiment 2: A method for patterning the surface of an azo polymer film by laser. In Embodiment 2, only the light treatment time is adjusted to 20s in step seven, and other steps remain unchanged. This process was observed in situ under a stereo microscope, and the patterns produced on the surface of the film were as follows: figure 2 shown.

Embodiment 3

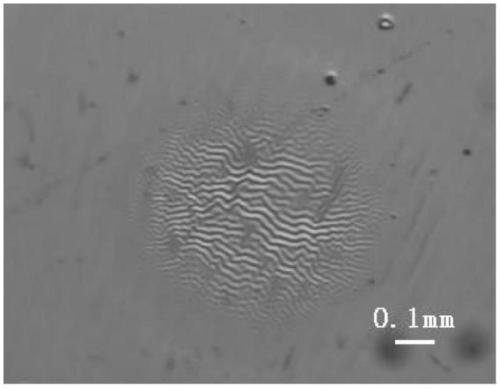

[0029] Embodiment 3: a kind of method that realizes the surface patterning of azo polymer film by laser, in embodiment 3, just in step one, the mass ratio of prepolymer and crosslinking agent is adjusted to 10:1, in step seven Adjust the light processing time to 2min, and keep other steps unchanged. This process was observed in situ under a stereo microscope, and the patterns produced on the surface of the film were as follows: image 3 shown.

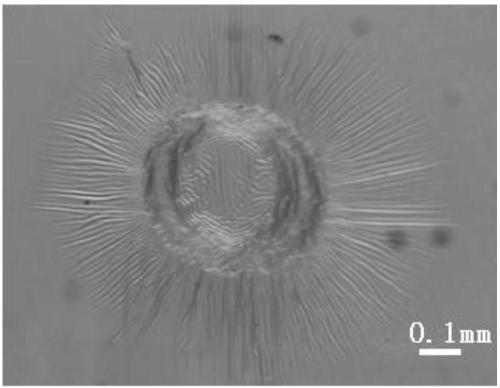

[0030] To sum up, the present invention achieves surface patterning of the side-chain azobenzene polymer film by adjusting the modulus of the laser and the substrate, and obtains different surface patterns by adjusting the modulus of the substrate and the illumination time. When the base modulus is low and the illumination time is long, a surface pattern with a random center, a concentric circle in the middle, and a radial surface pattern on the outermost side is formed; when the illumination time is short, no random wrinkle pattern o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com