Polyurethane latent curing agent, one-component polyurethane waterproof coating and preparation method thereof

A polyurethane curing agent and polyurethane waterproof technology, applied in the field of architectural waterproof coatings, can solve the problems of poor storage performance of finished coatings, shrinkage cavities, pinholes, dark bubbles, and high application costs, and achieve short reaction time, low reaction conditions, and high application costs. Apply low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

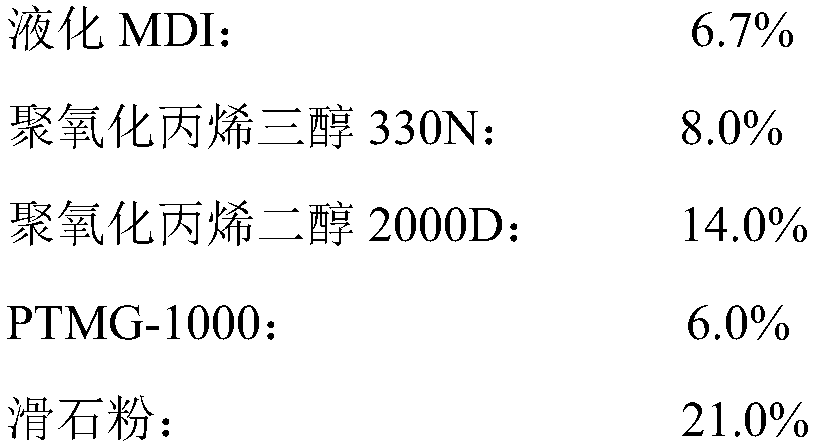

[0037] In terms of mass percentage, the raw materials of the high-performance one-component polyurethane waterproof coating in the present embodiment include the following components:

[0038]

[0039]

[0040] Among them, the catalyst is a mixture of triethylamine and dibutyltin dilaurate in a mass ratio of 2:8; the molecular weight of polyoxypropylene triol 330N is 4800, and the molecular weight of polyoxypropylene diol 2000D is 2000.

[0041]The preparation method of self-made latent curing agent A is as follows: put 116.20g of 1,6-hexamethylenediamine and 50g of water into a round-bottomed flask under nitrogen protection, and under rapid stirring, add 160.00g of n-butyraldehyde from the dropping funnel, and then Remove water and other volatile components (-0.1MPa) under negative pressure to obtain latent curing agent A.

[0042] The preparation method of above-mentioned one-component polyurethane waterproof coating, the steps are as follows:

[0043] (1) Put the pol...

Embodiment 2

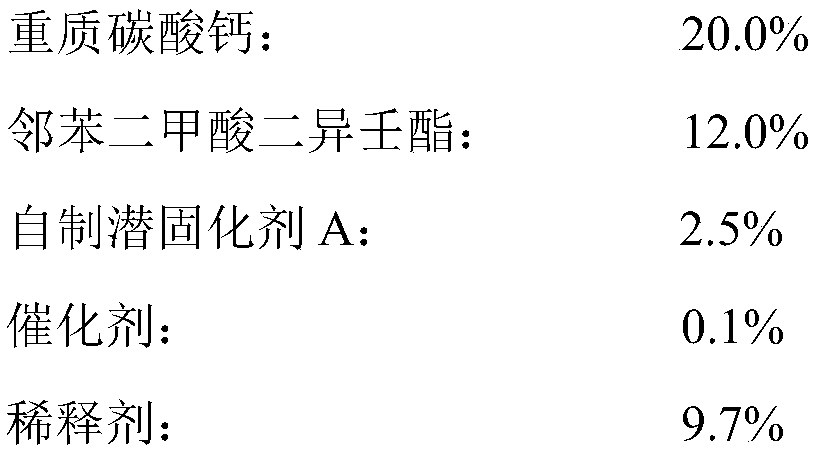

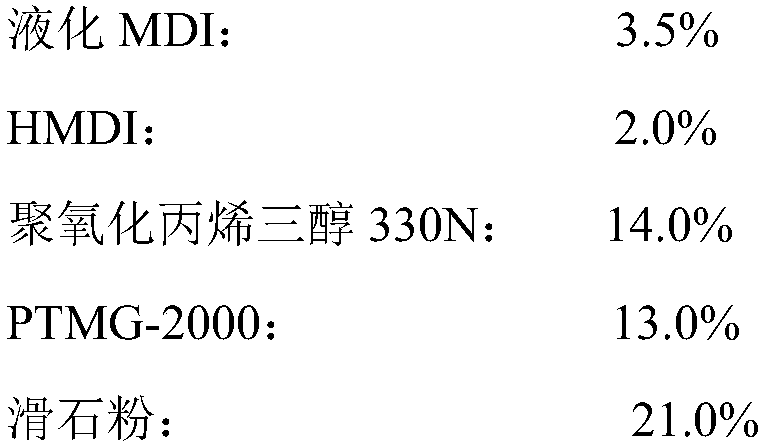

[0049] In terms of mass percentage, the raw materials of the high-performance one-component polyurethane waterproof coating in the present embodiment include the following components:

[0050]

[0051]

[0052] Wherein, the catalyst is a mixture of triethylamine and stannous octoate with a mass ratio of 2:8.

[0053] The preparation method of self-made latent curing agent B is as follows: put 116.20g of 1,6-hexamethylenediamine and 50g of water into a round-bottomed flask under nitrogen protection, and under rapid stirring, add 130.00g of propionaldehyde from the dropping funnel, and then Remove water and other volatile components (-0.1MPa) under negative pressure to obtain latent curing agent B.

[0054] The preparation method of high-performance one-component polyurethane waterproof coating, the steps are as follows:

[0055] (1) Put polyoxypropylene triol 330N, PTMG2000, talcum powder, light calcium carbonate, CP52, and liquid petroleum resin into the dispersion kett...

Embodiment 3

[0061] In terms of mass percentage, the raw materials of the high-performance one-component polyurethane waterproof coating in the present embodiment include the following components:

[0062]

[0063]

[0064] Wherein, the catalyst is a mixture of bismuth isooctanoate and stannous octoate with a mass ratio of 4:6.

[0065] Wherein, the preparation method of self-made latent curing agent C is: drop into 160.00g n-butyraldehyde and 40g toluene in the round bottom flask under nitrogen protection, under rapid stirring, add 108.14g phenylenediamine, reflux reaction 3 hours, then in Remove water and other volatile components (-0.1MPa) under negative pressure to obtain the product.

[0066] The preparation method of high-performance one-component polyurethane waterproof coating, the steps are as follows:

[0067] (1) Put the polyoxypropylene triol 330N, PCD2000, kaolin, heavy calcium carbonate, diisononyl phthalate, and CP52 according to the formula ratio into the dispersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com