Flower-shaped multistage structure molybdenum trioxide material induce by nickel-titanium alloy and preparation method and application thereof

A technology of nickel-titanium alloy and molybdenum trioxide, which is applied in the direction of structural parts, electrochemical generators, electrical components, etc., can solve the problem of poor cycle performance and magnification of negative electrode materials, and cannot meet the requirements of the structural integrity of negative electrode materials with volume changes. Unfavorable application and production problems, to achieve the effect of easy operation, improved cycle stability, and enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

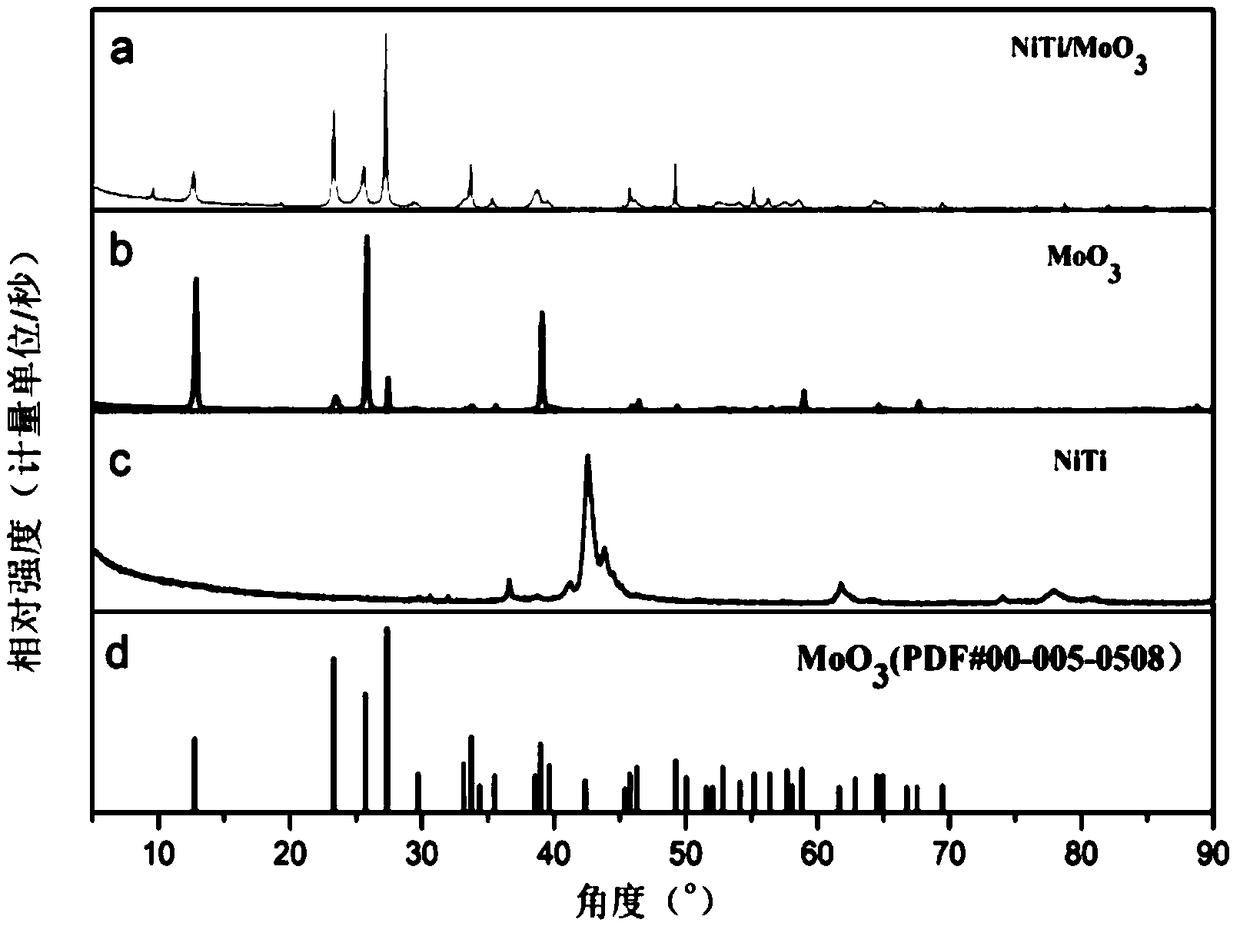

Image

Examples

Embodiment 1

[0042] (1) Analytical pure (NH 4 ) 6 Mo 7 o 24 4H 2 O (1.52g) was dissolved in deionized water (50mL), and stirred magnetically at 200 rpm for 15 minutes to obtain solution A;

[0043] (2) Under magnetic stirring, 9.1 mL of HNO with a solubility of 65% was added dropwise to solution A obtained in step (1). 3 , to obtain solution B;

[0044] (3) under magnetic stirring, add 0.228g, 60nm spherical NiTi alloy (the mass percent of Ni in the alloy composition is 55%) powder to the solution B obtained in step (2), to obtain solution C;

[0045] (4) The solution C obtained in step (3) was transferred to a tetrafluoroethylene-lined autoclave, and reacted at 180° C. for 24 hours.

[0046] (5) After the reaction is completed and cooled to room temperature, the reaction product obtained in step (4) is collected by centrifugation, washed with water and ethanol three times respectively, and then the reaction product is vacuum-dried at 60°C for 24 hours under a vacuum of 1000 Pa to ob...

Embodiment 2

[0050] (1) Analytical pure (NH 4 ) 6 Mo 7 o 24 4H 2 O (1.52g) was dissolved in deionized water (50mL), and magnetically stirred at 400 rpm for 12 minutes to obtain solution A;

[0051] (2) Under magnetic stirring, 9.1 mL of HNO with a solubility of 50% was added dropwise to the solution A obtained in step (1). 3 , to obtain solution B;

[0052] (3) under magnetic stirring, add 0.456g, 100nm near-spherical NiTi alloy (the mass percentage of Ni in the alloy composition is 56%) powder to the solution B obtained in step (2), to obtain solution C;

[0053] (4) The solution C obtained in step (3) was transferred to a tetrafluoroethylene-lined autoclave, and reacted at 210° C. for 3 hours.

[0054] (5) After the reaction is completed and cooled to room temperature, the reaction product obtained in step (4) is collected by centrifugation, washed 5 times with water and ethanol respectively, and then the reaction product is vacuum-dried at 80°C for 12 hours under a vacuum of 4000P...

Embodiment 3

[0058] (1) Analytical pure (NH 4 ) 6 Mo 7 o 24 4H 2 O (1.52g) was dissolved in deionized water (50mL), and magnetically stirred at 100 rpm for 18 minutes to obtain solution A;

[0059] (2) Under magnetic stirring, 9.1 mL of HNO with a solubility of 30% was added dropwise to the solution A obtained in step (1). 3 , to obtain solution B;

[0060] (3) under magnetic stirring, add 0.2g, 120nm spherical NiTi alloy (the mass percentage of Ni in the alloy composition is 54%) powder to the solution B obtained in step (2), to obtain solution C;

[0061](4) The solution C obtained in step (3) was transferred to a tetrafluoroethylene-lined autoclave, and reacted at 150° C. for 16 hours.

[0062] (5) After the reaction is completed and cooled to room temperature, the reaction product obtained in step (4) is collected by centrifugation, washed with water and ethanol for 4 times, and then the reaction product is vacuum-dried at 70°C for 18 hours under a vacuum of 2000Pa to obtain a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com