Preparation method of Kangshu (healthy and confortable) composite staple fiber

A technology of short fiber and Kangshu, which is applied in the field of preparation of Kangshu composite short fiber, can solve the problems of unsustainable antibacterial performance, damage to the PE structure of the cortex, and easy formation of burrs on the surface, etc., to achieve good bonding effect, smooth surface, and good The effect of the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of Kangshu composite staple fiber, the steps comprising:

[0026] 1) Purified terephthalic acid and ethylene glycol are mixed in proportion and sent to the esterification tank for esterification reaction. The esterification reaction temperature is 255-260 °C;

[0027] 2) The esterification product is sent to the polycondensation kettle through the oligomer pipeline for polycondensation reaction. At the same time, the catalyst is also injected into the oligomer pipeline and sent to the polycondensation kettle to produce PET. The catalyst is HMTS provided by Shanghai Huaming High Technology (Group) Co., Ltd. -PET type titanium series catalyst, the vacuum degree of precondensation reaction is controlled between 2-3KPa absolute pressure, the temperature is controlled at 250-255℃; the vacuum degree of final polymerization reaction is controlled between 0.1-0.2KPa absolute pressure, and the temperature is controlled at 275 -280°C;

[0028] 3) Polyethylen...

Embodiment 2

[0032] A preparation method of Kangshu composite staple fiber, the steps comprising:

[0033] 1) Purified terephthalic acid and ethylene glycol are mixed in proportion and sent to the esterification tank for esterification reaction. The esterification reaction temperature is 255-260 °C;

[0034]2) The esterification product is sent to the polycondensation kettle through the oligomer pipeline for polycondensation reaction. At the same time, the catalyst is also injected into the oligomer pipeline and sent to the polycondensation kettle to produce PET. The catalyst is HMTS provided by Shanghai Huaming High Technology (Group) Co., Ltd. -PET type titanium series catalyst, the vacuum degree of precondensation reaction is controlled between 2-3KPa absolute pressure, the temperature is controlled at 250-255℃; the vacuum degree of final polymerization reaction is controlled between 0.1-0.2KPa absolute pressure, and the temperature is controlled at 275 -280°C;

[0035] 3) Polyethylene...

Embodiment 3

[0039] A preparation method of Kangshu composite staple fiber, the steps comprising:

[0040] 1) Purified terephthalic acid and ethylene glycol are mixed in proportion and sent to the esterification tank for esterification reaction. The esterification reaction temperature is 255-260 °C;

[0041] 2) The esterification product is sent to the polycondensation kettle through the oligomer pipeline for polycondensation reaction. At the same time, the catalyst is also injected into the oligomer pipeline and sent to the polycondensation kettle to produce PET. The catalyst is HMTS provided by Shanghai Huaming High Technology (Group) Co., Ltd. -PET type titanium series catalyst, the vacuum degree of precondensation reaction is controlled between 2-3KPa absolute pressure, the temperature is controlled at 250-255℃; the vacuum degree of final polymerization reaction is controlled between 0.1-0.2KPa absolute pressure, and the temperature is controlled at 275 -280°C;

[0042] 3) Polyethylen...

PUM

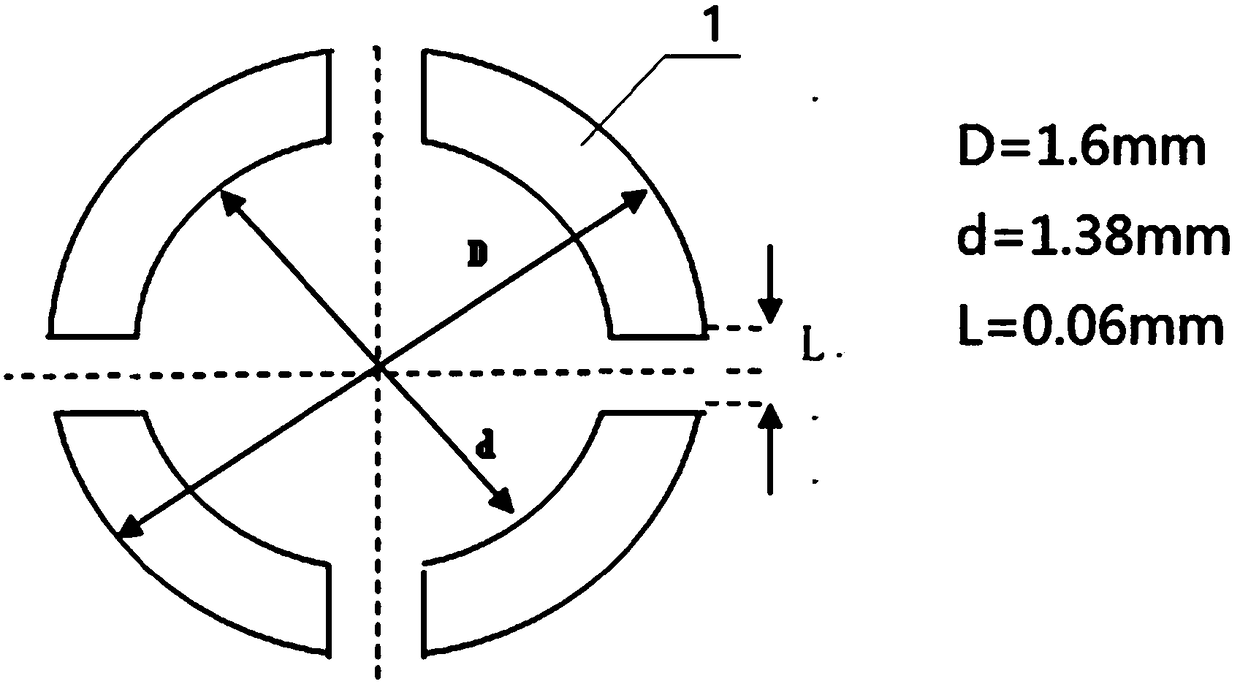

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com