Polybenzimidazole film with nanometer porous structure and preparation method thereof

A polybenzimidazole membrane and polybenzimidazole technology are applied in the field of polybenzimidazole membrane and its preparation, which can solve the problems of inability to accurately control the size and distribution of pores, decrease in proton conductivity, loss of phosphoric acid, etc., and achieve ultra-fast Phosphoric acid adsorption rate, excellent stability, effect of large internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

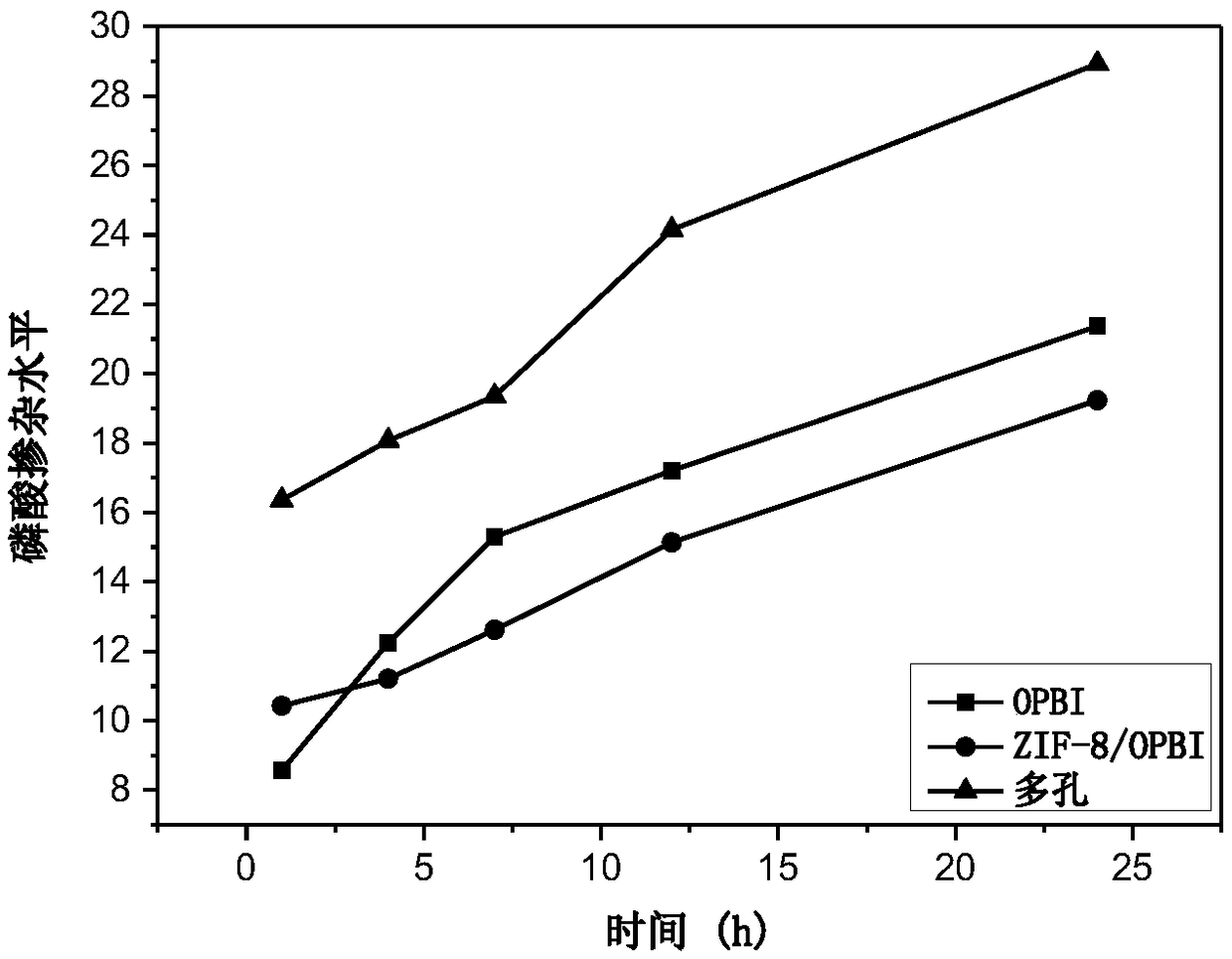

[0029] 1) Ultrasonically disperse ZIF-8 nanoparticles with a size of about 100nm in DMAc, and add them to the DMAc solution of OPBI. The mass ratio of ZIF-8 and OPBI is 2:8, ultrasonically disperse and stir vigorously to make the two evenly mixed, Use a 400-mesh filter cloth to filter out impurities, cast it on a clean glass plate, dry it in a vacuum oven at 80°C for 12 hours, at 100°C for 12 hours, at 120°C for 12 hours, and finally vacuumize and keep it at 120°C for 12 hours to obtain polybenzone imidazole film.

[0030] 2) Soak the obtained polybenzimidazole film in 85% (wt) phosphoric acid at 120°C for 24h, then wash with boiling water for 5h to remove residual etchant, and dry at 120°C for 12h; repeat the above washing and drying process twice, A polybenzimidazole membrane with a nanoporous structure is obtained.

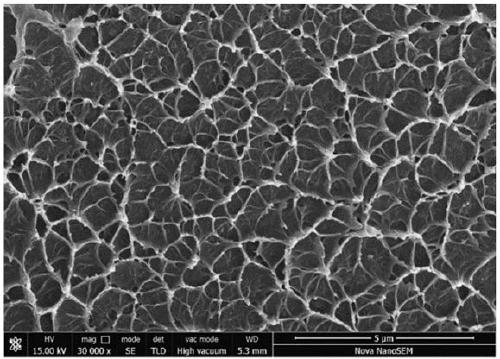

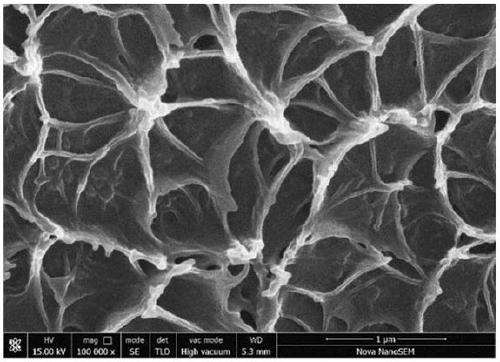

[0031] The polybenzimidazole film of the nanoporous structure obtained in the present embodiment has been carried out scanning electron microscope characteriz...

Embodiment 2

[0034] 1) Ultrasonically disperse ZIF-8 nanoparticles with a size of about 150nm in DMAc, and add them to the DMAc solution of OPBI. The mass ratio of ZIF-8 and OPBI is 2:8, ultrasonically disperse and stir vigorously to make the two evenly mixed, Use a 400-mesh filter cloth to filter out impurities, cast it on a clean glass plate, dry it in a vacuum oven at 80°C for 12 hours, at 100°C for 12 hours, at 120°C for 12 hours, and finally vacuumize and keep it at 120°C for 12 hours to obtain polybenzone imidazole film.

[0035] 2) Soak the obtained polybenzimidazole membrane in 85% (wt) phosphoric acid at 120°C for 12h, then wash with boiling water for 5h to remove residual etchant, and dry at 120°C for 12h to obtain polybenzoimidazole with nanoporous structure. The imidazole membrane has a pore size of about 850nm. The phosphoric acid doping level at 120°C for 24 hours can reach 25, and the proton conductivity of the doped phosphoric acid film at 200°C for 24 hours is 115mS / cm. ...

Embodiment 3

[0037] 1) Ultrasonically disperse ZIF-8 nanoparticles with a size of about 200nm in DMAc, and add them to the DMAc solution of OPBI. The mass ratio of ZIF-8 and OPBI is 1:9, ultrasonically disperse and stir vigorously to make the two evenly mixed. Use a filter cloth to filter out impurities, cast on a clean glass plate, dry in a vacuum oven at 80°C for 12h, at 100°C for 12h, at 120°C for 12h, and finally vacuumize and keep at 120°C for 12h to obtain a polybenzimidazole film .

[0038] 2) Soak the obtained polybenzimidazole membrane in 85% (wt) phosphoric acid at 120°C for 24h, then wash with boiling water for 5h to remove residual etchant, and dry at 120°C for 12h to obtain polybenzoimidazole with nanoporous structure. The imidazole membrane has a pore size of about 750nm. The phosphoric acid doping level at 120°C for 24 hours can reach 23, and the proton conductivity of the doped phosphoric acid film at 200°C for 24 hours is 100mS / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com