A kind of preparation method of pH-responsive comb structure polycarboxylic acid

A technology of comb-like structure and polycarboxylate, which is applied in the field of pH-responsive polycarboxylate for cement concrete, to achieve the effects of low energy consumption, simple and controllable reaction process, and prevention of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

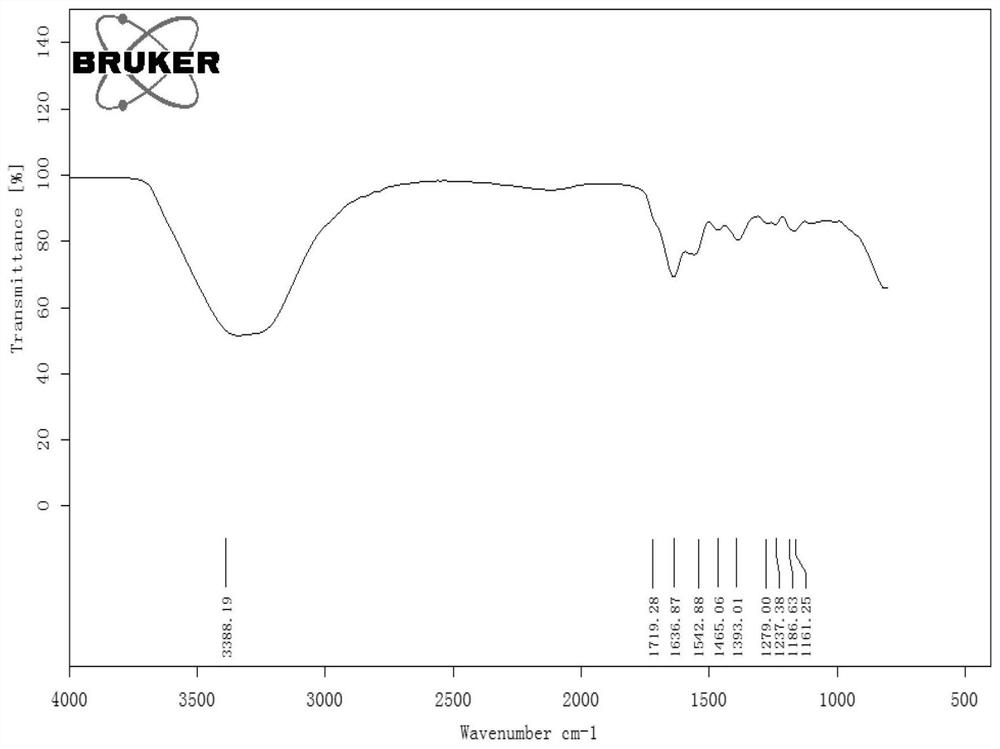

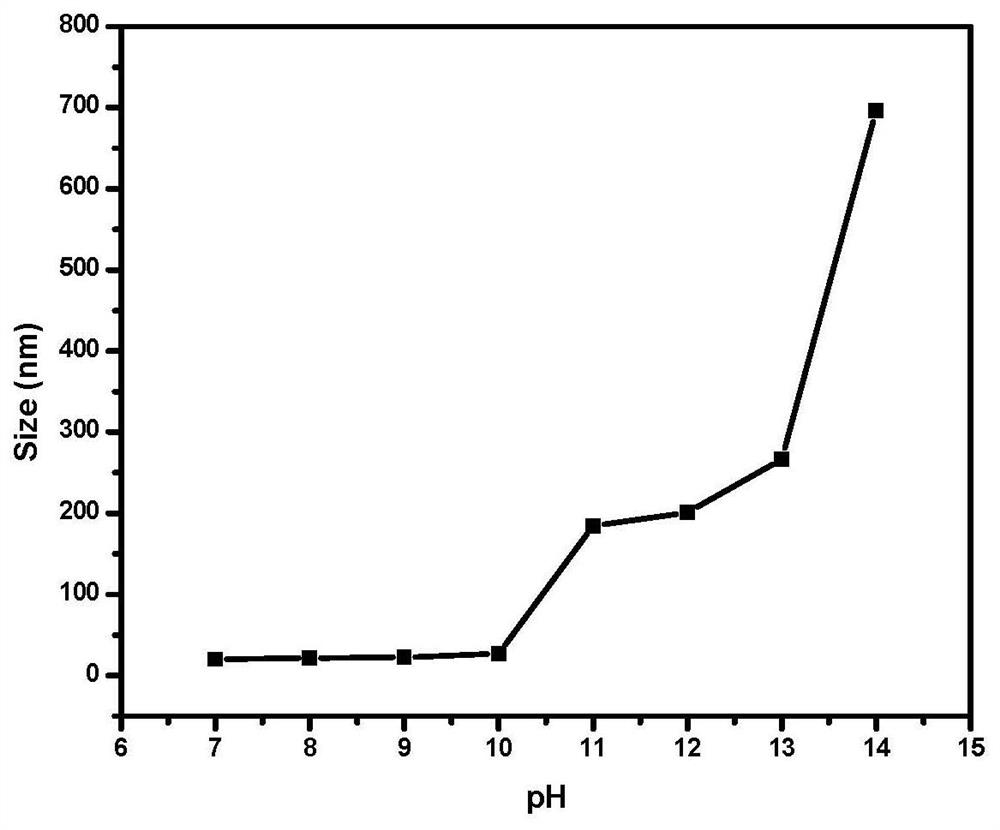

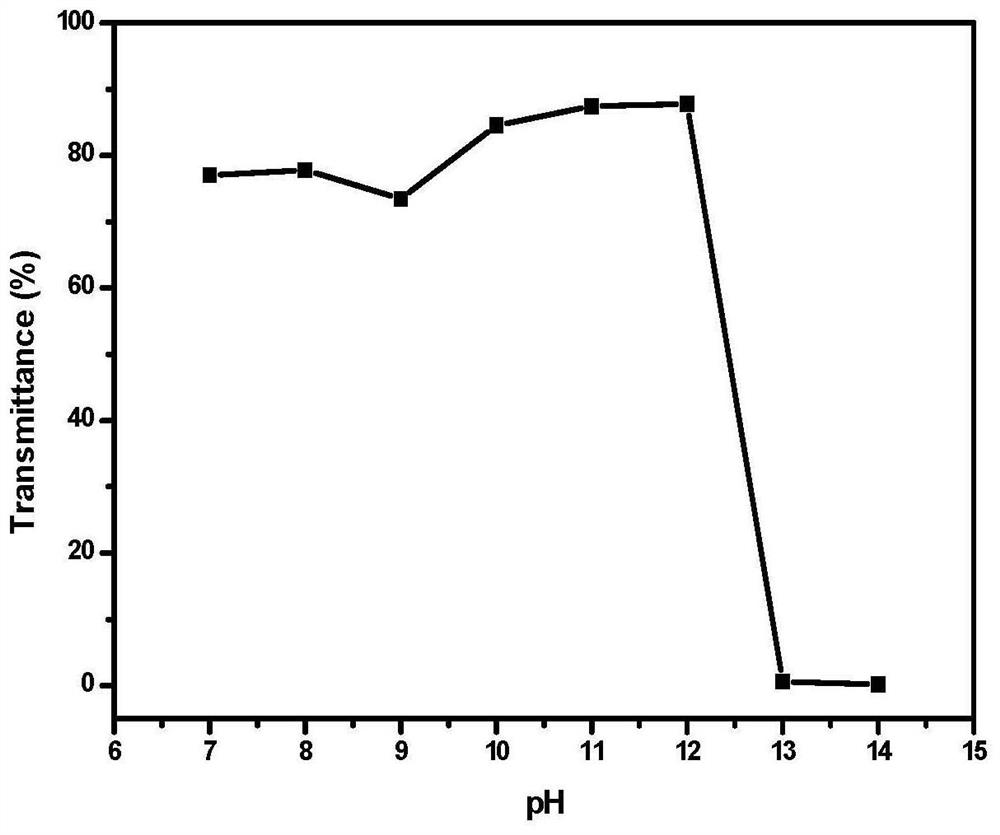

Method used

Image

Examples

Embodiment 1

[0034]First, 90g of N,N-dimethylformamide, 30g of ethyl acrylate and 32.75g of 3-mercaptopropionic acid isooctyl ester were added to the reactor, stirred and heated to 60°C, and then 5.96g of azobisisoheptaonitrile was added dropwise A mixed solution with 8.94g of N,N-dimethylformamide for 10 hours, after the dropping, continue to react at a constant temperature of 60°C for 5 hours to obtain a self-polymerized product polyethyl acrylate solution; adjust the temperature of the obtained self-polymerized product to 60°C , Add 24.29g tert-dodecyl mercaptan and stir for 35 minutes until it is evenly mixed, then add 377.31g dimethylaminoethyl methacrylate, 29.80g azobisisoheptonitrile and 44.71g N,N-dimethyl The mixed solution of methyl formamide was added for 10 hours. After the addition, the reaction was continued at 60°C for 5 hours, and then N,N-dimethylformamide was removed by vacuum distillation to obtain the graft copolymerized product; 407.31 g of graft copolymer was obtained. The...

Embodiment 2

[0036]First, 30g of tetrahydrofuran, 30g of methyl acrylate and 12.54g of isopropanol were added to the reactor, stirred and heated to 50°C, and then a mixed solution of 2.86g of azobisisobutyronitrile and 2.86g of tetrahydrofuran was added dropwise for 12 hours. After the addition, continue to react at a constant temperature of 50°C for 6 hours to obtain a self-polymerized product polymethyl acrylate solution; adjust the temperature of the obtained self-polymerized product to 50°C, add 35.22g of n-dodecyl mercaptan and stir for 40 minutes until it is mixed Evenly, add dropwise a mixed solution of 498.27g dimethylaminoethyl acrylate, 28.57g azobisisobutyronitrile and 28.57g tetrahydrofuran for 12 hours. After the addition, continue to react at a constant temperature of 50°C for 6 hours, and then remove by distillation under reduced pressure. Tetrahydrofuran to obtain graft copolymerization product; mix 528.27g graft copolymerization product with 62.64g deionized water, stir and heat...

Embodiment 3

[0038]First, 270g of dimethyl sulfoxide, 30g of amyl acrylate and 1.27g of isopropanol were added to the reactor, stirred and heated to 70°C, and then 6.56g of tert-butyl peroxybenzoate and 59.02g of dimethyl The mixed solution of sulfoxide was 8 hours, and after the dropping, the reaction was continued at 70°C for 4 hours to obtain the self-polymerization product polypentyl acrylate solution; adjust the temperature of the obtained self-polymerization product to 80°C, and add 32.03g n-dodecyl Stir the mercaptan for 25 minutes until it is evenly mixed, then add dropwise a mixed solution of 66.55g 4-vinylpyridine, 19.67g tert-butyl peroxybenzoate and 177.04g dimethyl sulfoxide for 6 hours, and continue to keep constant temperature after the addition is complete React at 80°C for 3 hours, then remove the dimethyl sulfoxide by vacuum distillation to obtain the graft copolymerization product; mix 96.55g of the graft copolymerization product with deionized water, stir and raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com