Sewage treatment agent and preparation method thereof

A sewage treatment agent and pretreatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of high input cost, achieve high safety, complex The effect of improved performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

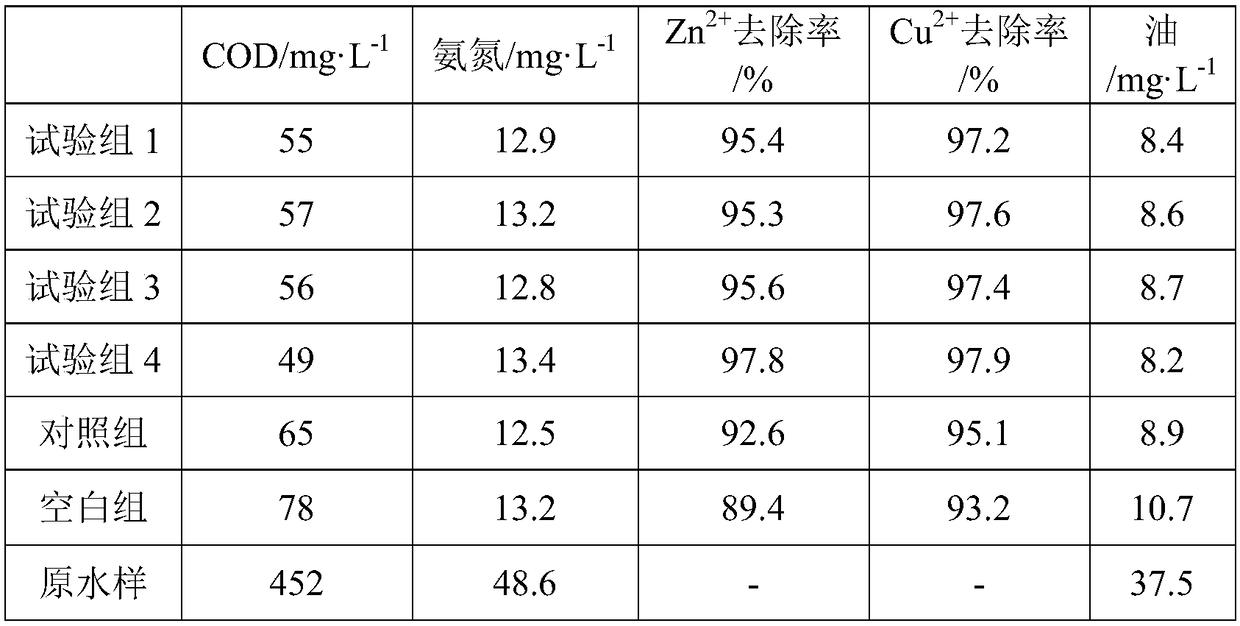

Examples

Embodiment 1

[0028] A sewage treatment agent, including oxidatively modified lignosulfonate in the sewage treatment agent, the above-mentioned oxidatively modified lignosulfonate is obtained by adding lignosulfonate to hydrogen peroxide in the presence of alkali The oxidant is obtained by oxidative modification with trimethylamine hydrochloride and 5-aminolevulinic acid as initiators. The oxidative modification products of lignosulfonate have functional groups such as phenolic hydroxyl group, alcoholic hydroxyl group, carboxyl group, carbonyl group, sulfonic acid group, etc., and carboxyl group and sulfonic acid group are flocculation functional groups; Cooperative function is a scale-inhibiting functional group; sulfonic acid group and phenolic hydroxyl group can be adsorbed on the metal surface to protect the metal, and the phenolic ether structure has the effect of stabilizing the protective film, so it has the effect of corrosion inhibition and rust prevention. The oxidative modificati...

Embodiment 2

[0039] A sewage treatment agent, comprising the following raw materials in parts by weight: 39 parts of lignosulfonate oxidation modification products, 25 parts of polyacrylamide and derivatives thereof, 12 parts of diatomite, 11 parts of sulfur Urea, 9 parts of acrolein, 27 parts of aminated attapulgite, 13 parts of propylene oxide.

[0040] A kind of preparation method of above-mentioned sewage treatment agent, its concrete steps are as follows:

[0041] 1) adding sodium sulfite to lignin at a weight ratio of 1:4.3, and reacting for 3.5 hours at a pH of 12 and a temperature of 98°C to obtain lignosulfonate;

[0042] 2) After the lignosulfonate is prepared into an aqueous solution with a concentration of 29%, the pH is adjusted to 8, heated to 80° C., and then 22% and 0.53% of the weight of the lignosulfonate are added respectively. Oxidant and initiator, Insulation and stirring reaction at a speed of 450r / min for 1.25h can obtain the oxidative modification product of lignos...

Embodiment 3

[0048] A sewage treatment agent, comprising the following raw materials in parts by weight: 38 parts of lignosulfonate oxidation modification products, 22 parts of polyacrylamide and derivatives thereof, 14 parts of diatomaceous earth, 12 parts of sulfur Urea, 7 parts of acrolein, 28 parts of aminated attapulgite, 15 parts of propylene oxide.

[0049] A kind of preparation method of above-mentioned sewage treatment agent, its concrete steps are as follows:

[0050] 1) adding sodium sulfite to lignin at a weight ratio of 1:4.8, and reacting for 3 hours at a pH of 11 and a temperature of 95°C to obtain lignosulfonate;

[0051] 2) After the lignosulfonate is prepared into an aqueous solution with a concentration of 28.5%, the pH is adjusted to 10, heated to 85° C., and then 20.5% and 0.42% of the weight of the lignosulfonate are added respectively. Oxidant and initiator, Insulate and react at a speed of 500r / min for 1h to obtain the oxidatively modified product of lignosulfonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com