Circulating utilizing method of using biomass ash and slag to modify converter steelmaking slag to remove phosphorous

A biomass ash, converter steel slag technology, applied in recycling technology, application, phosphate fertilizer and other directions, to achieve the effects of easy absorption, important economic and environmental benefits, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

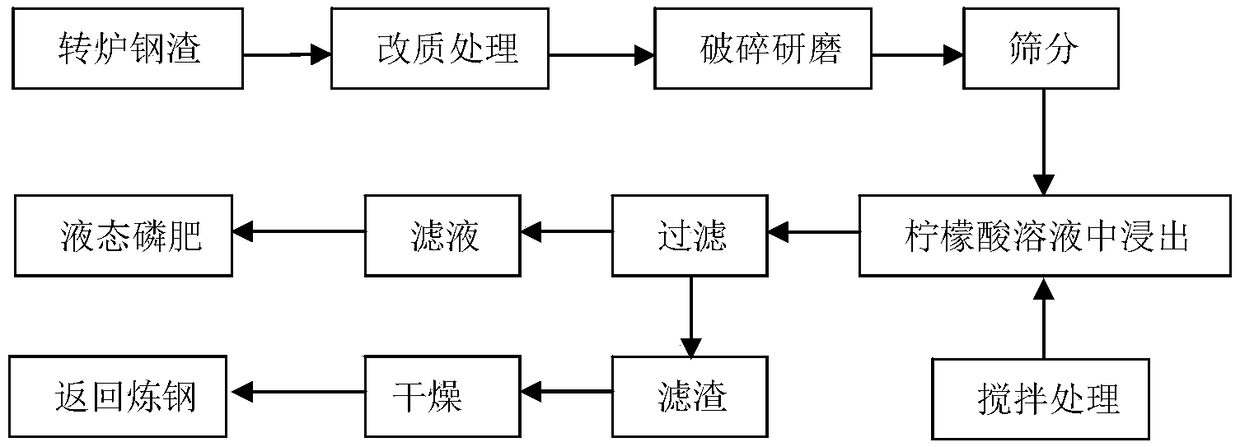

[0042] Select the converter steel slag produced by the converter duplex process of producing automobile plates in a steel factory, and the recycling method of biomass ash slag modification converter steel slag dephosphorization in this embodiment, its flow chart is as follows figure 1 As shown, it specifically includes the following steps:

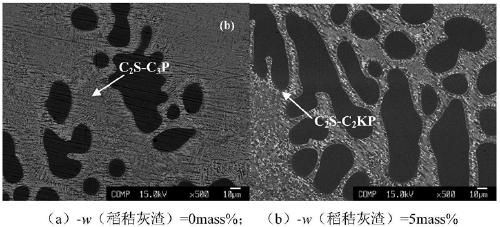

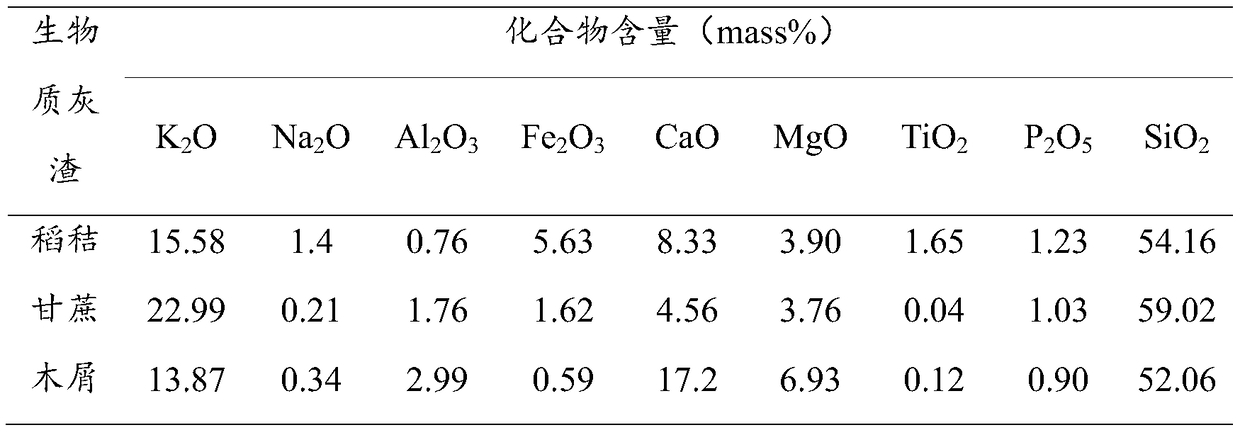

[0043] (1) Add rice straw ash under 200 mesh sieves to molten steel slag when slag removal, the ash amount is 5mass%;

[0044] (2) insulation reaction at 1723K for 90min;

[0045] (3) Control the cooling rate to be 5K / min, and slowly drop to room temperature;

[0046] (4) The slag sample particle size of the cooled modified steel slag crushed, ground and screened is 75-150 μm, and the chemical composition of the dephosphorized slag is detected by an X-ray fluorescence spectrometer, and the results are shown in Table 2;

[0047] (5) Prepare 400 mL of citric acid solution with a pH value of 5 and add it to the beaker, and control the acid...

Embodiment 2

[0058] Select the converter steel slag produced by the converter duplex process of producing automobile plates in a steel factory, and the recycling method of the biomass ash slag modification converter steel slag dephosphorization of the present embodiment specifically includes the following steps:

[0059] (1) Add the sugarcane ash under the 200 mesh sieve to the molten steel slag when the slag is discharged, and the ash amount is 8mass%;

[0060] (2) insulation reaction at 1823K for 60 minutes;

[0061] (3) Control the cooling rate to be 4K / min, and slowly drop to room temperature;

[0062] (4) The slag sample particle size of the cooled modified steel slag crushed, ground and screened is 45-48 μm, and the chemical composition of the dephosphorized slag is detected by an X-ray fluorescence spectrometer, and the results are shown in Table 3;

[0063] (5) Prepare 400 mL of citric acid solution with a pH value of 6 and add it to the beaker, and control the acidity and alkalin...

Embodiment 3

[0074] Select the converter steel slag produced by the converter double slag process of producing pipeline steel in a steel factory, and the recycling method of biomass ash slag modification converter steel slag dephosphorization in this embodiment specifically includes the following steps:

[0075] (1) Add rice straw and sawdust ash (mass ratio is 1:1) under 200 mesh sieves to the molten steel slag during slag removal, and the ash amount is 8mass%;

[0076] (2) insulation reaction at 1783K for 80min;

[0077] (3) Control the cooling rate to be 3K / min, and slowly drop to room temperature;

[0078] (4) The slag sample particle size of the cooled modified steel slag crushed, ground and screened is 45-48 μm, and the chemical composition of the dephosphorized slag is detected by an X-ray fluorescence spectrometer, and the results are shown in Table 4;

[0079] (5) citric acid solution 400mL that the preparation pH value is 7 joins in the beaker, controls solution acidity and alka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com