A processing method of chromium-zirconium copper microporous tube and chromium-zirconium copper microporous tube

A processing method and microporous tube technology, applied in the processing of chrome-zirconium copper microporous tubes, in the field of chrome-zirconium copper microporous tubes, can solve the problems of increased friction rate between welding wire and the inner hole of the conductive tip, high damage rate of the conductive tip, and metal Problems such as excessive loss, to achieve the effect of good coaxiality of the inner hole, high yield and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

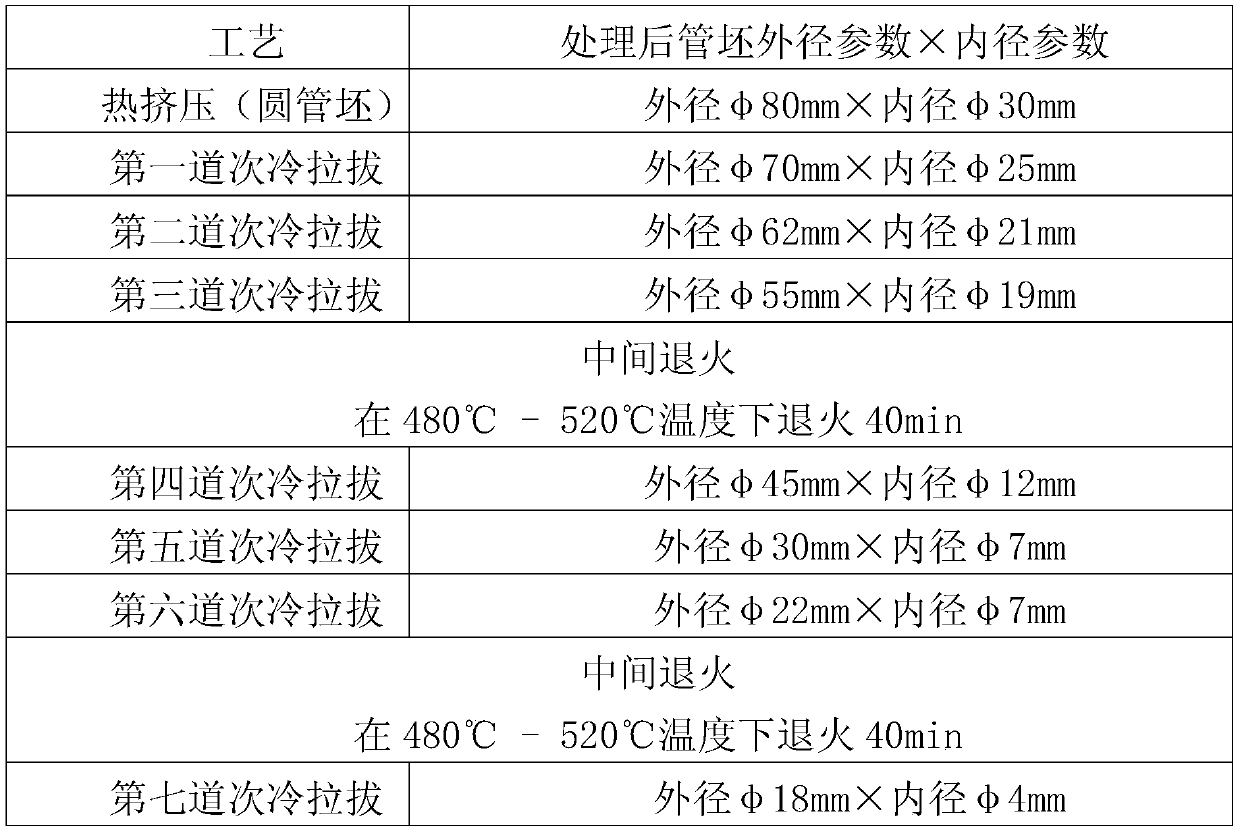

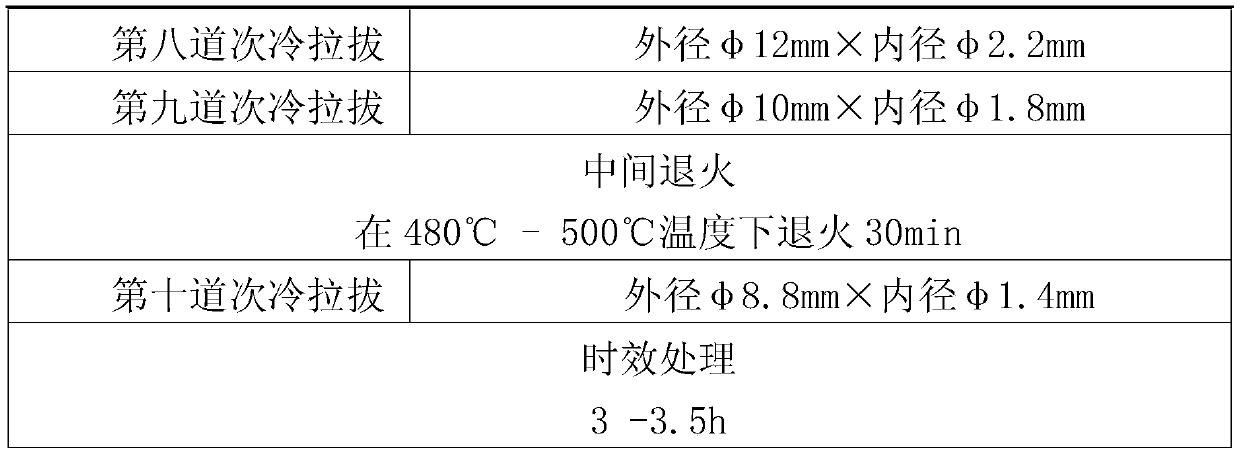

[0024] A processing method for a chromium-zirconium copper microporous tube, comprising the steps of:

[0025] Step 1: Calculate metal chromium, metal zirconium and electrolytic copper according to the mass percentage of unit elements, metal chromium is 0.4-0.8%, metal zirconium is 0.3-0.6%, and the balance is electrolytic copper. Melting and casting into a solid round ingot; analyze the chemical composition of the cast solid round ingot to ensure that its chemical composition meets the requirements of metal chromium content between 0.4-0.8%, metal zirconium content between 0.3-0.6%, impurities The content is less than 0.5%, and the balance is electrolytic copper; metal flaw detection and surface inspection are carried out on the cast solid round ingot, and after all are qualified, sawing is carried out according to the length required by the process;

[0026] Step 2: Hot extruding the sawn solid round ingot to obtain a round tube billet with an outer diameter of φ80mm×inner d...

Embodiment 2

[0030] A processing method for a chromium-zirconium copper microporous tube, comprising the steps of:

[0031] Step 1: Proportioning electrolytic copper, metal chromium, and metal zirconium according to chemical composition requirements, wherein, in terms of the mass percentage of unit elements: Al accounts for 0.1-0.25, Mg accounts for 0.1-0.25, and Cr accounts for 0.4-0.8 , Zr accounts for 0.3-0.6, Fe accounts for 0.05, Si accounts for 0.05, the sum of other impurities does not exceed 0.5, and the balance is Cu; Melt and cast into a solid round ingot after mixing; analyze the chemical composition of the cast solid round ingot to ensure that its chemical composition meets the above ratio requirements; conduct metal flaw detection and surface inspection on the cast solid round ingot , after they are all qualified, saw the section according to the length required by the process;

[0032]Step 2: Hot extruding the sawn solid round ingot to obtain a round tube billet with an oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com