A server integrated delivery power cord tracing mechanism

A server and power line technology, applied in the field of server integration, can solve the problems of messy wiring, time-consuming operation and maintenance, low aesthetics and low recognizability, and achieve the effect of shortening the wiring distance and reducing the difficulty of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

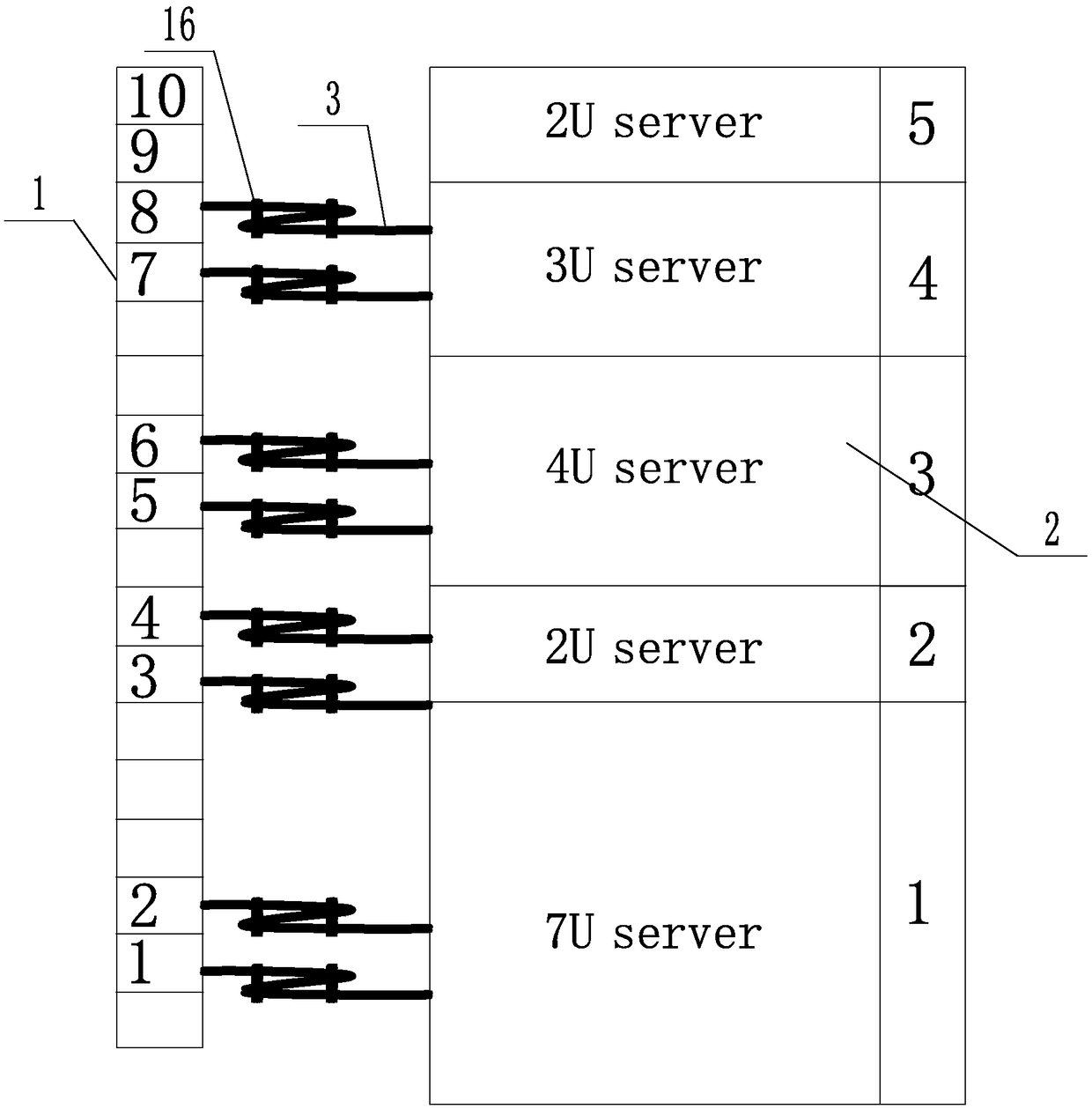

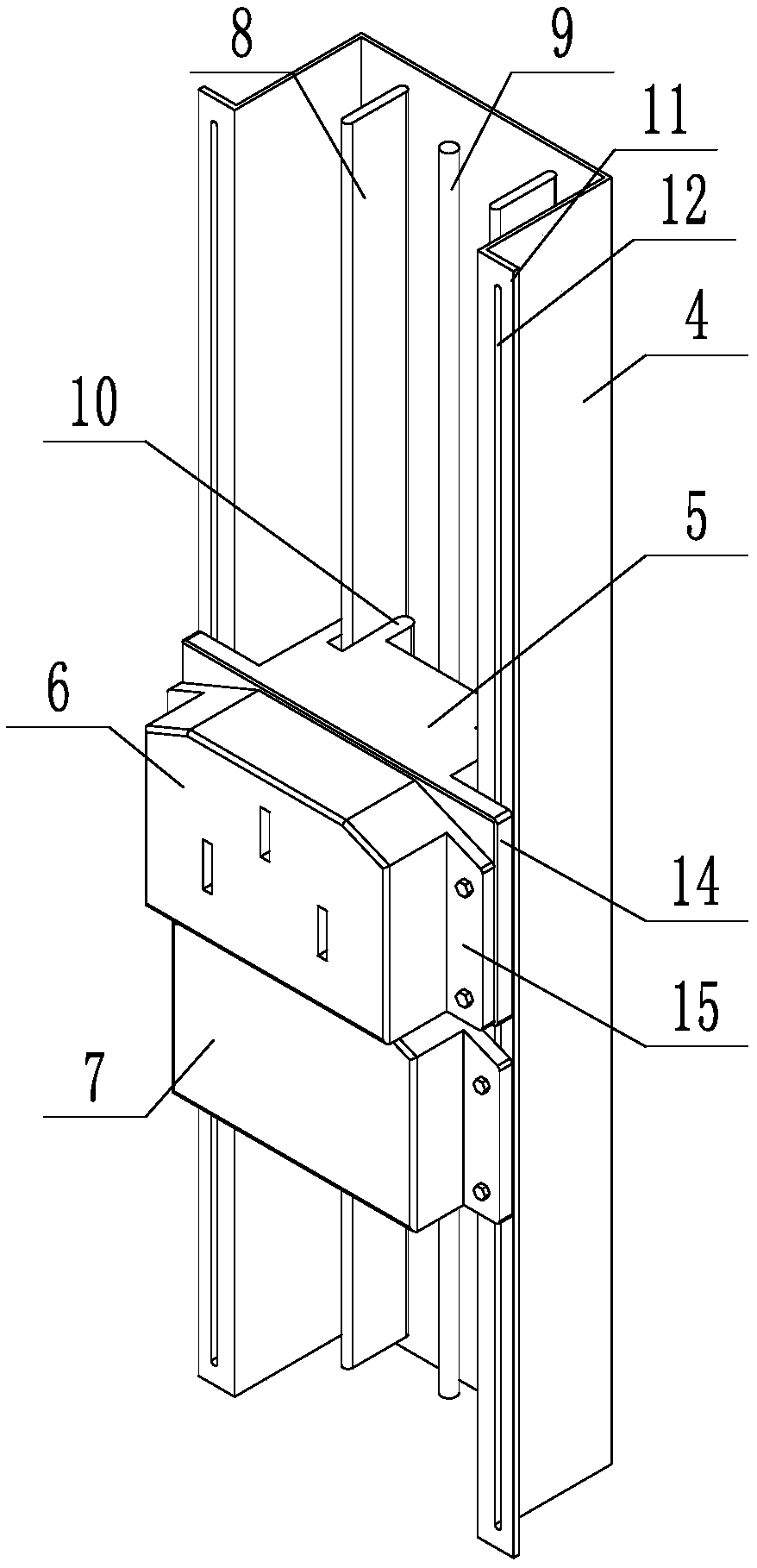

[0033] A server integrated delivery power cord routing mechanism, including a PDU socket 1, a server 2, a cable 3 connecting the PDU socket 1 and the server 2, the PDU socket 1 includes a PDU shell 4, and a crown clip 5 , plug female seat 6 and model female seat 7, corresponding to plug female seat 6 figure 1 The number 1 to number 10 in the box, the model base 7 corresponds to figure 1 In the blank square, the PDU shell 4 is provided with a copper bar 8 and a ground wire 9, the rear end of the crown clip 5 is connected to the copper bar 8 and the ground wire 9, the front end of the crown clip 5 is provided with a wire 13, and the crown clip 5 It is connected with the plug female seat 6 through wires 13, the first connecting plate 11 is provided at both ends of the PDU housing 4, and the connecting plate 11 is provided with a long hole 12, and the crown clip 5 and the plug female seat 6 are connected with the first connecting plate 11 , when the server is integrated and deliv...

Embodiment 2

[0037] A splint 19 is provided between the second connecting plate 14 at the two ends of the crown clamp 5 and the first connecting plate 11, and the splint 19 is connected with the crown clamp 5 by screws. The position corresponding to the first card slot 17 is provided with a second card slot 18, the first card slot 17 and the second card slot 18 are provided with a positioning rod 20, and the positioning rod 20 is located in the first card slot 17 and the second card slot 18 In the spliced groove, two ends of the PDU housing 4 are provided with positioning grooves 21 , and the positioning rods 20 cooperate with the positioning grooves 21 .

[0038] Steps 22 are provided in the first draw-in groove 17 and the second draw-in groove 18, and a baffle plate 23 is provided on the positioning rod 20, and the baffle plate 23 contacts with the step 22, and a spring 24 is sleeved on the positioning rod 20, and one end of the spring 24 In contact with the baffle plate 23 , the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com