Geological radar detecting scheme for back-filled grouting of shield segment in water-rich gravel stratum

A technology of shield segment and geological radar, which is applied to measurement devices, radio wave measurement systems, reflection/re-radiation of radio waves, etc. Accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

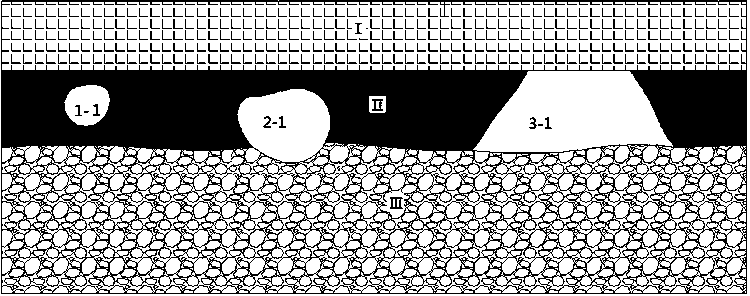

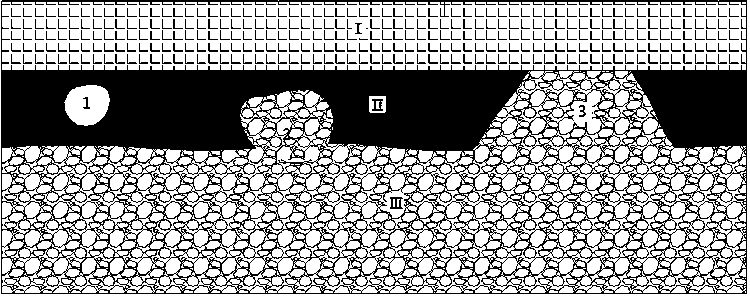

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Nanning Rail Transit Line 2 Chaoyang Square ~ Railway Station

[0036] 1) Detect on-site interference sources, mainly including wire (cable) interference, segment joint interference, segment screw interference, and tunnel ring structure interference to radar signals. Wire (cable) interference is a typical hyperbolic shape on radar. Segment seam interference is in the form of strong reflection on the radar, and the location is relatively fixed. Segment bolts are strong reflection in the radar and decay slowly. Because the tunnel is ring-shaped, the radar antenna is not absolutely shielded, and a small amount of energy is scattered into the air and reflected by the inner wall of the tunnel to form a certain amount of interference on the radar. However, this type of interference energy is relatively weak, and the interference has already exceeded the target detection layer. time, so the interference to the on-site detection is limited. The secondary reflection o...

Embodiment 2

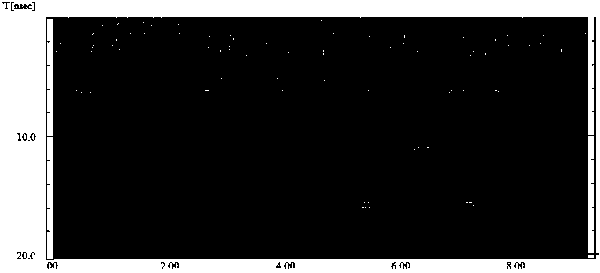

[0050] Example 2 Nanning Rail Transit Line 2 No. 33 Middle School ~ Xiuxiang Station

[0051] The model of the shield segment at this station is X-4, and the strength of the shield is C50. The Italian K2-FW radar is used for detection on site. The electromagnetic wave reflection signal of the grouting layer forms interference. The wave velocity of the detection shield segment is 11.2cm / ns, the wave velocity of the grouting layer is 8.7cm / ns, the sampling time window is 40ns, the sampling point distance is 3.2cm, and the radar antenna is 400MHz. According to the wave velocity calibrated on site value, the thickness of the segment is calculated as 30cm, the thickness of the grouting layer is 16-21cm, there is no radar reflection clutter behind the grouting layer, the surrounding rock properties on the surface are uniform, and the radar reflection wave between the grouting layer and the surrounding rock is continuous in phase, There is no obvious hyperbolic reflection, and there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com