Novel dry fully-prefabricated assembled concrete frame connecting system

A technology of prefabricated concrete and prefabricated assembly, which is applied in the direction of building types, protected buildings/shelters, and building components. It can solve problems such as difficult repairs and irreparable repairs, and achieve quality assurance, fast construction progress, and convenient manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The content of the present invention will be described below in conjunction with specific embodiments.

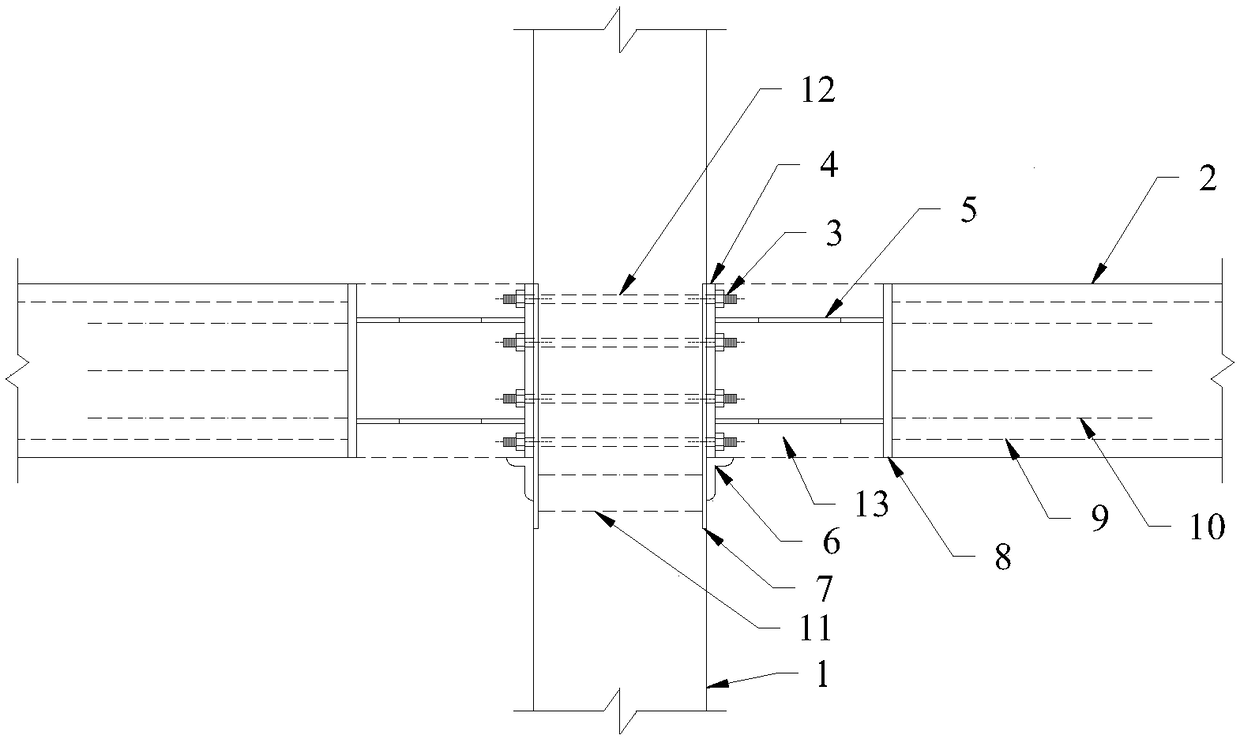

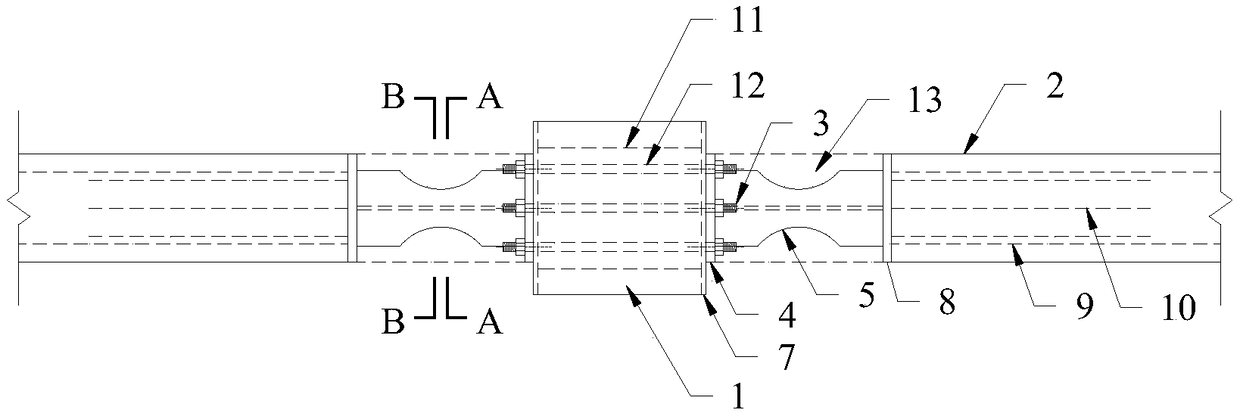

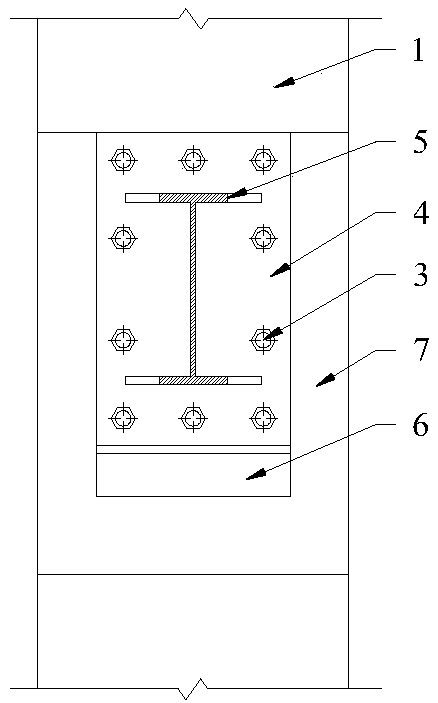

[0037] Such as Figure 1 to Figure 13 Shown: is the structural schematic diagram of the novel dry fully prefabricated concrete frame connection system of the present invention.

[0038] The novel dry fully prefabricated concrete frame connection system (such as Figure 13shown), including: beam-to-column dry ductile connection and inter-column dry connection;

[0039] One, such as Figure 1-7 Shown: beam-column ductile connection components mainly include: precast concrete column 1, precast concrete beam 2, section steel weakening section 5, precast concrete beam end anchor plate 8, section steel connection end plate 4, embedded steel lining plate 7, steel support 6. It is composed of connecting bolt 3, pre-embedded steel lining plate anchoring steel bar 11 and fireproof filling material 13; one side of the precast concrete beam end anchor plate 8 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com