3D hard gold process

A technology and hard gold technology, applied in the field of precious metal processing, can solve the problems affecting the precision of 3D hard gold and the accuracy of wax molds, and achieve the effects of improving precision and quality, slowing down the rise of PH value, and improving cathodic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

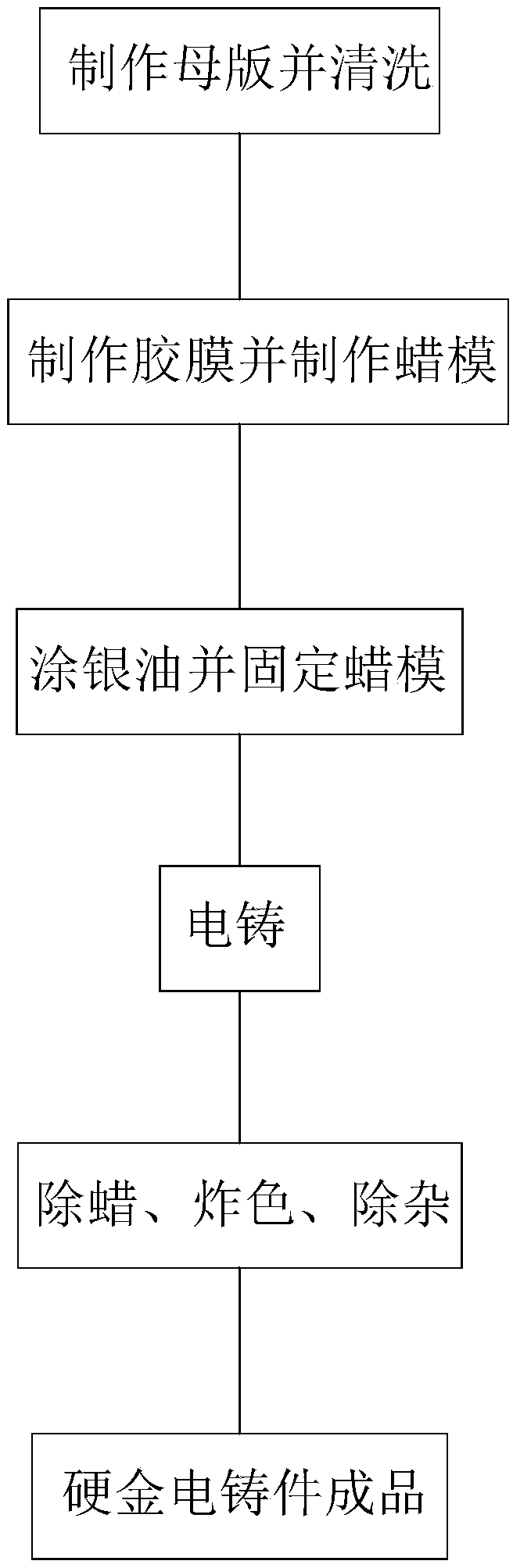

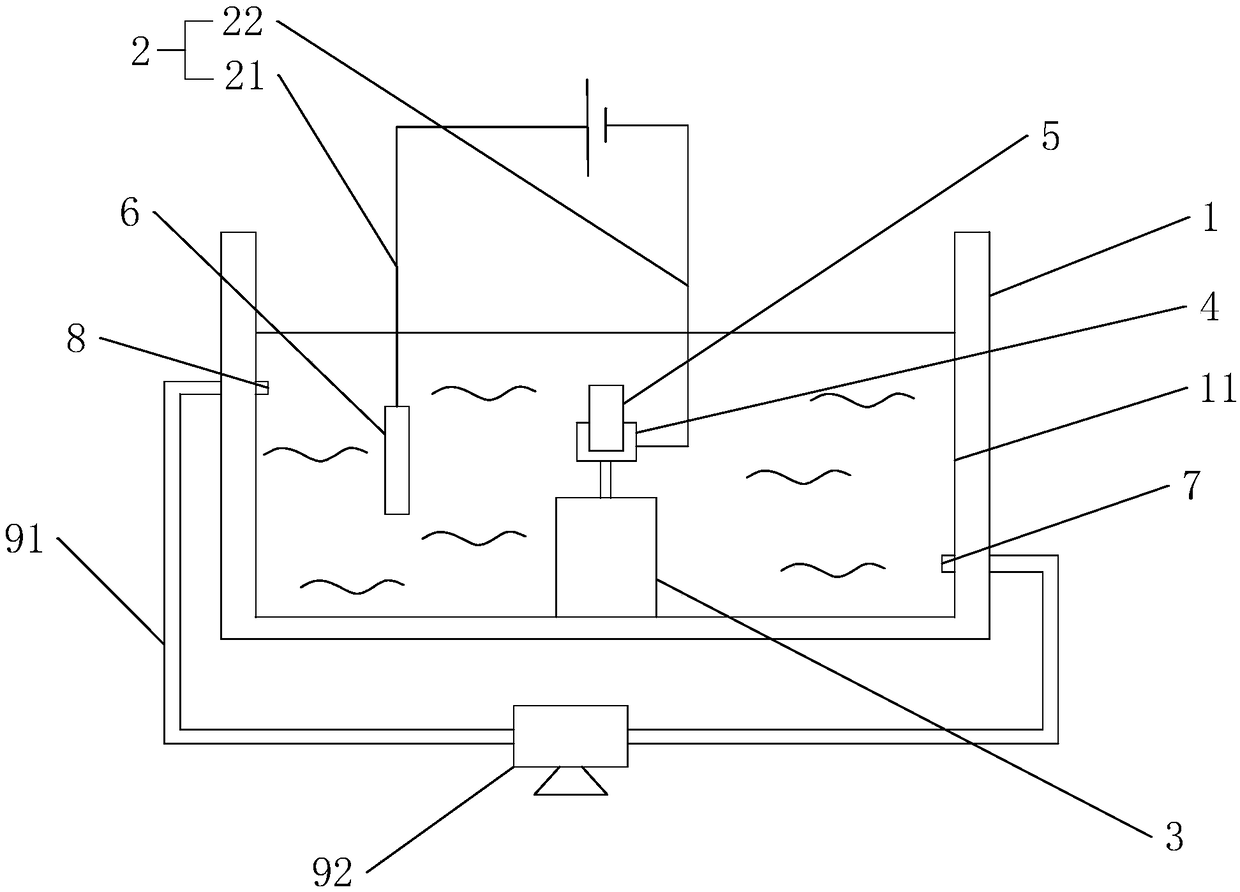

[0032] Embodiment 1: as figure 1 As shown, a 3D hard gold process, the steps include: S1, making a master and cleaning; S2, using the master made in step S1 to make an adhesive film, and using the adhesive film to make a wax plate that can replicate the shape of the master Model, and repair; S3, apply silver oil to the wax model, hang the wax model on the workpiece fixing frame of the electroforming cylinder, so that the wax model rotates with the workpiece fixing frame during the electroforming process; S4, start the electroforming cylinder Carry out electroforming to obtain an electroforming part; S5, remove wax from the electroforming part, remove wax, fry color, and remove impurities; S6, perform mold-holding process, sandblasting process and calendering process on the semi-finished jewelry piece in step E in sequence.

[0033] Among them, the steps of making a master in S1 are as follows: S11, making 3D model data through computer software; S12, importing the prepared 3D ...

Embodiment 2

[0039] Embodiment 2: The difference between embodiment 2 and embodiment 1 is only that the content of sodium chlorophyllin is different, and the content of sodium chlorophyllin in embodiment 2 is 10g / L.

Embodiment 3

[0040] Embodiment 3: The difference between embodiment 3 and embodiment 1 is only that the content of sodium chlorophyllin is different, and the content of sodium chlorophyllin in embodiment 3 is 12.5g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com