Method of reducing iron consumption for semi-steel smelting

A technology for steel smelting and iron consumption, applied in the field of reducing iron consumption in semi-steel smelting, can solve the problems of chemical heat loss, large burning loss of exothermic elements carbon and manganese, difficulty in heating up and eating more scrap steel, etc., to reduce consumption, increase production capacity, increase The effect of adding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

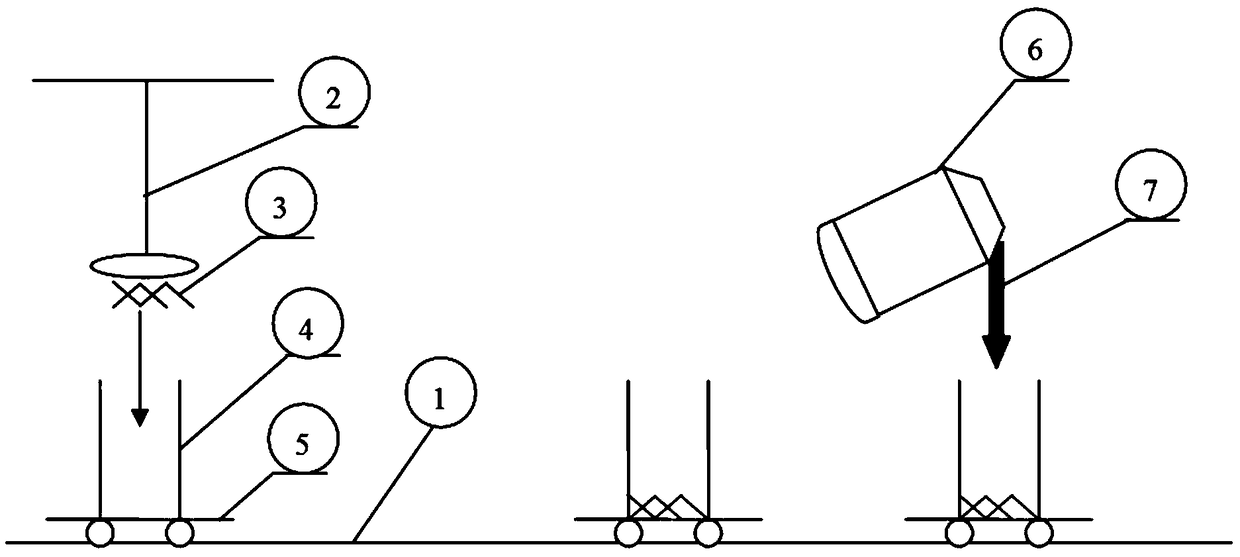

[0030] (1) the semi-steel ladle that completes vanadium extraction to semi-steel smelting a cycle production cycle is placed on the semi-steel car;

[0031] (2) Add scrap steel bars with a diameter of ≤25mm and a length of 500-700mm into the semi-steel ladle with an electromagnetic crane. The amount of scrap steel bars added is 500Kg / semi-steel ladle, and the surplus heat brought by the entry and exit of the semi-steel in the semi-steel ladle is used for preheating Add scrap steel bar 3 in the half ladle;

[0032] (3) semi-steel car operation transports the semi-steel ladle of above-mentioned step (2) to the vanadium extracting converter, and the vanadium extracting converter is turned over and 8Ot semi-steel is blended into the semi-steel ladle of the above-mentioned step (2), and the steel scrap in the semi-steel ladle Melting with the impact and high temperature of semi-steel;

[0033] (4) Hoist the semi-steel ladle in the above step (3) above the semi-steel furnace by dri...

Embodiment 2

[0036] (1) the semi-steel ladle that completes vanadium extraction to semi-steel smelting a cycle production cycle is placed on the semi-steel car;

[0037] (2) Add scrap steel bars with a diameter of ≤25mm and a length of 500-700mm into the semi-steel ladle with an electromagnetic crane. The amount of scrap steel bars added is 600Kg / semi-steel ladle, and the surplus heat brought by the entry and exit of the semi-steel in the semi-steel ladle is used for preheating Add scrap steel bar 3 in the half ladle;

[0038] (3) semi-steel car operation transports the semi-steel ladle of above-mentioned step (2) to the vanadium extracting converter, and the vanadium extracting converter is turned over and 8Ot semi-steel is blended into the semi-steel ladle of the above-mentioned step (2), and the steel scrap in the semi-steel ladle Melting with the impact and high temperature of semi-steel;

[0039] (4) After 3 minutes, use the driving to lift the semi-steel ladle of the above step (3) ...

Embodiment 3

[0042] (1) the semi-steel ladle that completes vanadium extraction to semi-steel smelting a cycle production cycle is placed on the semi-steel car;

[0043] (2) Add scrap steel bars with a diameter of ≤25mm and a length of 500-700mm into the semi-steel ladle with an electromagnetic crane. The amount of scrap steel bars added is 700Kg / semi-steel ladle, and the surplus heat brought by the entry and exit of the semi-steel in the semi-steel ladle is used for preheating Add scrap steel bar 3 in the half ladle;

[0044] (3) semi-steel car operation transports the semi-steel ladle of above-mentioned step (2) to the vanadium extracting converter, and the vanadium extracting converter is turned over and 8Ot semi-steel is blended into the semi-steel ladle of the above-mentioned step (2), and the steel scrap in the semi-steel ladle Melting with the impact and high temperature of semi-steel;

[0045] (4) After 5 minutes, hoist the semi-steel ladle of the above step (3) above the semi-ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com