Roller way kiln firing method for lightweight foamed ceramic plates

A technology of foamed ceramics and roller kiln, which is applied in the production of ceramic materials, ceramic products, and applications. It can solve the problems of poor overall product uniformity, difficult oxidation of the formula system, and long firing cycle to reduce oxidation reactions. Stage time, shortened firing cycle, excellent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

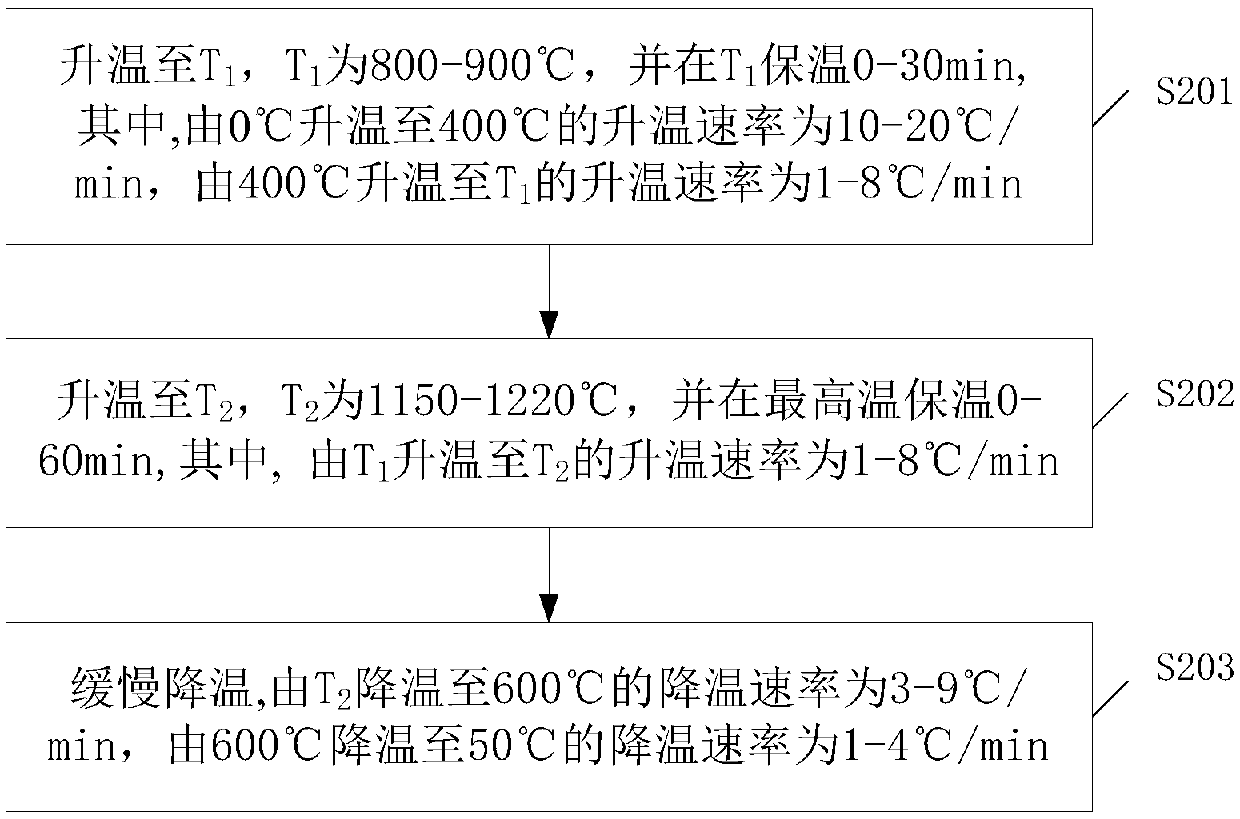

[0066] Correspondingly, such as image 3 As shown, the present invention provides a kind of preparation method of foamed ceramic light board, comprising:

[0067] S101, mixing the raw materials according to the proportion, and ball milling to make powder;

[0068] The ball milling can be wet milling or dry milling. The wet milling process includes: adding 30-40% water to the raw material, putting it into a ball mill for ball milling, milling until the residue on a 250-mesh sieve is less than 1%, and then passing through a spray tower to mill powder to obtain a water content of 5-40%. 10% powder.

[0069] S102, distributing the powder to obtain a green body;

[0070] S103, firing the green body through a roller kiln or a tunnel kiln to obtain a semi-finished product;

[0071] S104, cutting and grinding the semi-product to obtain a finished product.

[0072] After firing, it is necessary to grind the upper and lower surfaces of the green body and cut the edges.

[0073] Th...

Embodiment 1

[0079] (1) Formula: tile polishing waste 95.5%, foaming agent 0.5%, manganese dioxide stabilizer 4%.

[0080] (2) Preparation method:

[0081] The above raw materials are mixed according to the proportion, transported to the ball mill for ball milling, and sieved to a 250-mesh sieve with a residue of less than 1%, and then through the slurry storage tank and transfer tank to the spray tower for spray granulation, and the obtained powder The material is passed through the feeding cart and enters the roller kiln for firing. The firing method is as follows:

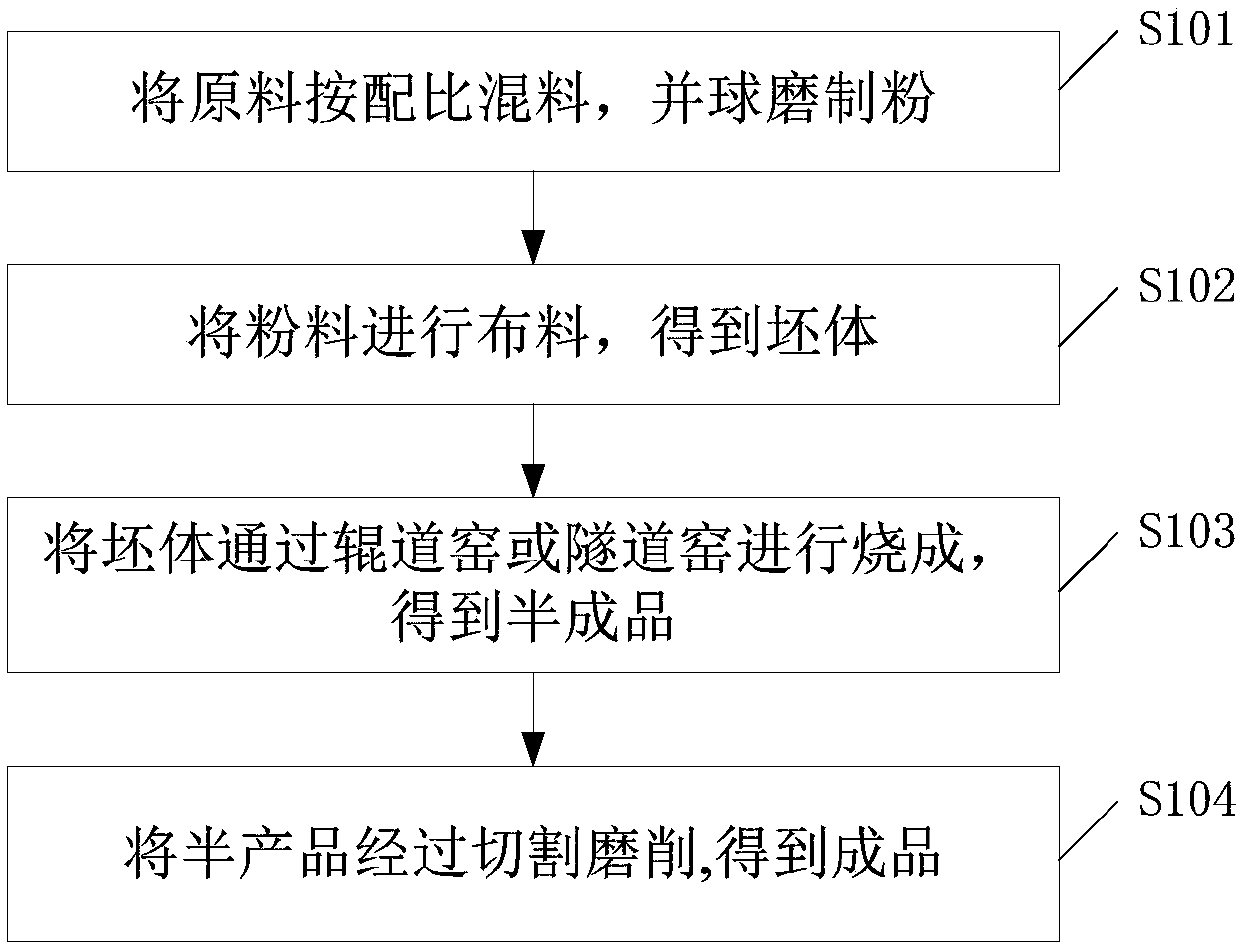

[0082] (a) Raise the temperature to 800°C and keep it at 800°C for 20 minutes, wherein the heating rate from 0°C to 400°C is 10°C / min, and the heating rate from 400°C to 800°C is 3°C / min;

[0083] (b) Raise the temperature to 1150°C and keep it at the highest temperature for 40 minutes, wherein the heating rate from 800°C to 1150°C is 3°C / min;

[0084] (c) Slowly lower the temperature, the cooling rate from 1150°C to 600°C...

Embodiment 2

[0087] (1) Formula: tile polishing waste 90%, clay 1%, feldspar 8.8%, foaming agent 0.1%, manganese dioxide stabilizer 0.1%.

[0088] (2) Preparation method:

[0089] The above raw materials are mixed according to the proportion, transported to the ball mill for ball milling, and sieved to a 250-mesh sieve with a residue of less than 1%, and then through the slurry storage tank and transfer tank to the spray tower for spray granulation, and the obtained powder The material is passed through the feeding cart and enters the roller kiln for firing. The firing method is as follows:

[0090] (a) Raise the temperature to 820°C and keep it at 820°C for 15 minutes, wherein the heating rate from 0°C to 400°C is 15°C / min, and the heating rate from 400°C to 820°C is 5°C / min;

[0091] (b) Raise the temperature to 1170°C and keep it at the highest temperature for 30 minutes, wherein the heating rate from 820°C to 1170°C is 4°C / min;

[0092] (c) Slowly lower the temperature, the cooling r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com