Combined scale inhibition dispersant for coal gasification system and application method thereof

A technology of anti-scaling dispersant and application method, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., and can solve the problem of low tolerance of calcium ions, iron ions and silicate ions , The scale inhibition and dispersion performance of water treatment chemicals are not ideal, and the water treatment effect cannot be achieved, so as to achieve good chemical stability, prevent and alleviate the formation of scale flakes, and improve the effect and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

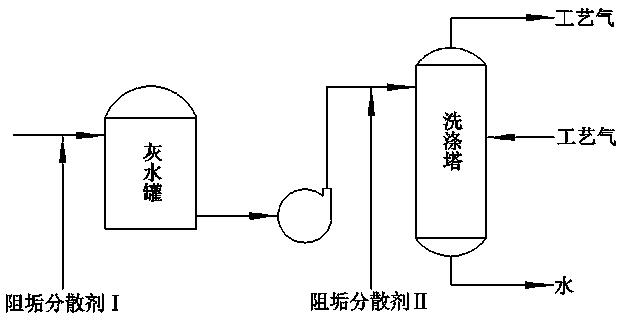

Image

Examples

Embodiment 1

[0035]Step 1. Dissolve 100g of maleic anhydride in 200g of water, stir and heat, and gradually add 12g of initiator ferrous ammonium sulfate, control the reaction temperature at 100°C, and carry out polymerization reaction for 5 hours;

[0036] Step 2. Cool down the system. When the temperature drops to 60°C, gradually add 50g of ethylenediaminetetramethylenephosphonic acid and 100g of water into the solution, and stir for 30 minutes to obtain scale inhibitor dispersant I;

[0037] Step 3: Divide scale inhibitor dispersant I into two equal parts, add 5g of polyethylene glycol ether to one of them, and continue stirring for 30 minutes to obtain scale inhibitor dispersant II.

Embodiment 2

[0039] Step 1. Dissolve 100g of maleic anhydride in 200g of water, stir and heat, and gradually add 12g of initiator ferrous ammonium sulfate at the same time, control the reaction temperature at 120°C, and carry out polymerization reaction for 5 hours;

[0040] Step 2. Cool down the system. When the temperature drops to 80°C, gradually add 50g of ethylenediaminetetramethylenephosphonic acid and 100g of water into the solution, and stir for 30 minutes to obtain scale inhibitor dispersant I;

[0041] Step 3: Divide scale inhibitor dispersant I into two equal parts, add 5g of polyethylene glycol ether to one of them, and continue stirring for 30 minutes to obtain scale inhibitor dispersant II.

Embodiment 3

[0043] Step 1. Dissolve 50g of acrylic acid and 50g of 2-acrylamide-2-methylpropanesulfonic acid in 200g of water, stir and heat, and at the same time gradually add 10g of initiator ammonium persulfate, control the reaction temperature at 70°C, and carry out polymerization reaction , reacted for 6 hours;

[0044] Step 2. Cool down the system. When the temperature drops to 40°C, gradually add 100g of 1-hydroxyethyl-1,1-diphosphonic acid and 200g of water into the solution, and stir for 30 minutes to obtain scale inhibitor dispersant I;

[0045] Step 3: Divide scale inhibitor dispersant I into two equal parts, add 10 g of polyethylene glycol ether to one of them, and continue stirring for 30 minutes to obtain scale inhibitor dispersant II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com