Hand carving knife

A kind of engraving knife and manual technology, applied in the direction of artist's hand tools, decorative arts, etc., can solve the problems of difficult cutting edge 51 cutting process, difficult control of operation accuracy, etc., to achieve convenient cutting work, reduce precision control requirements, high surface quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

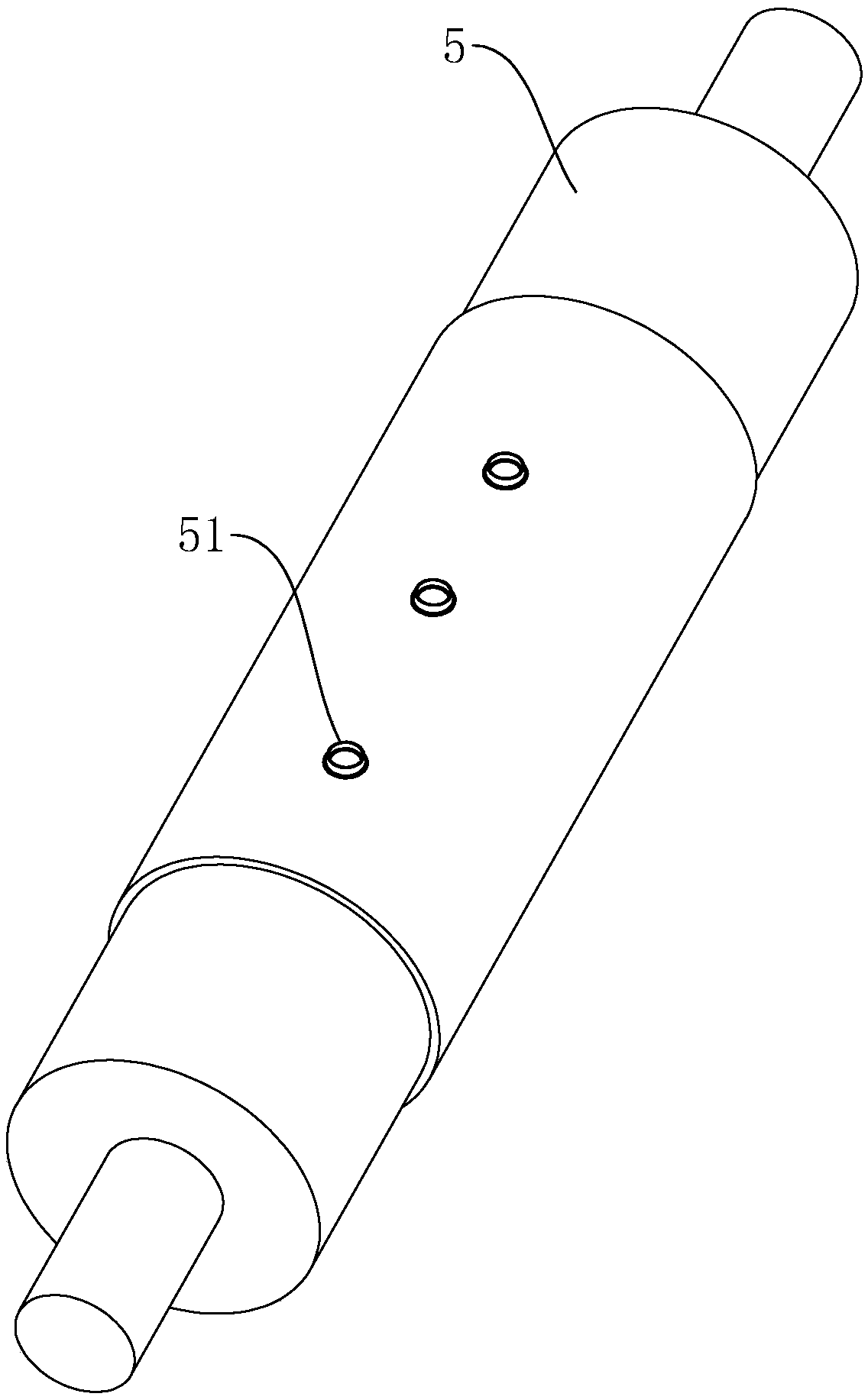

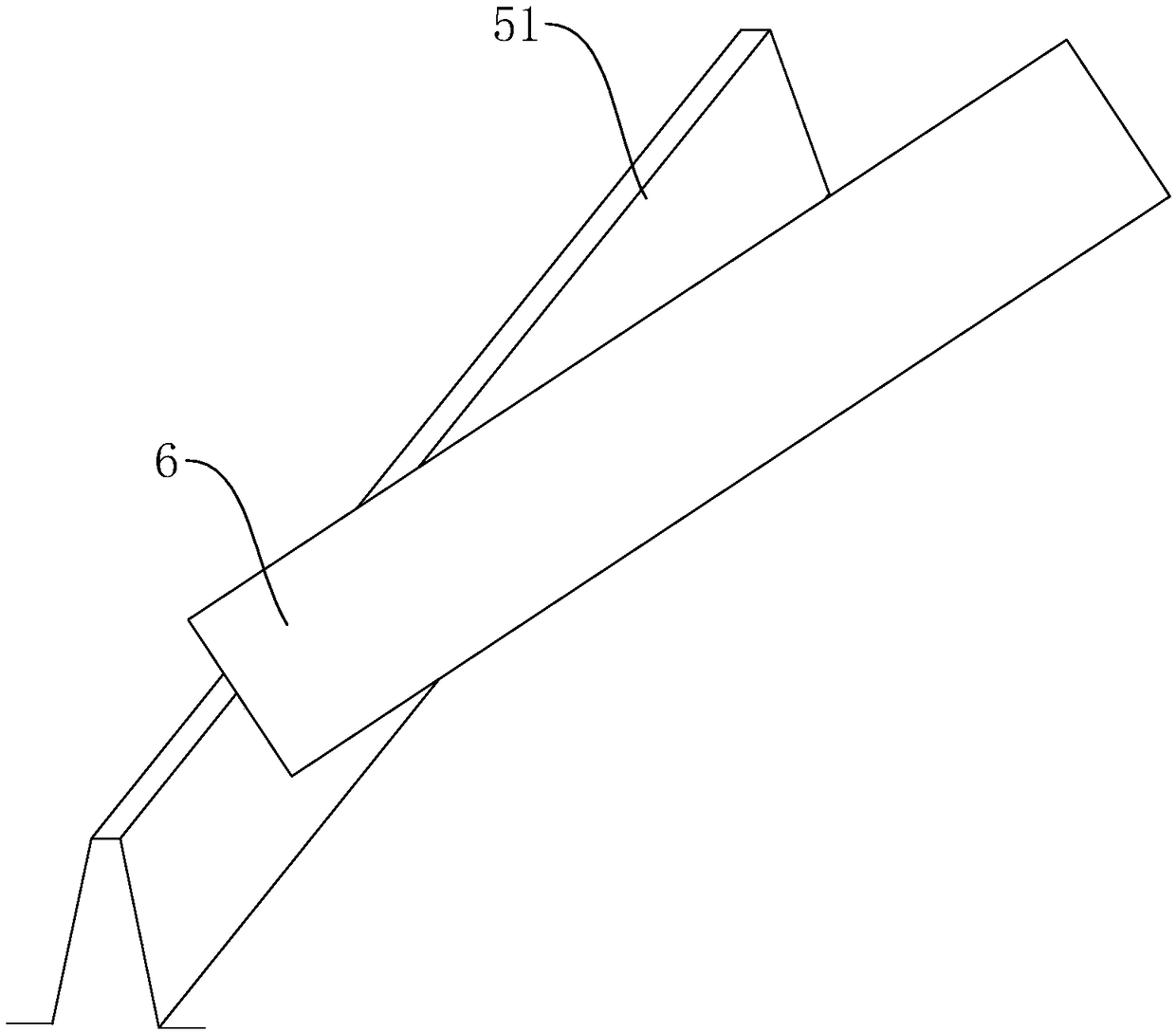

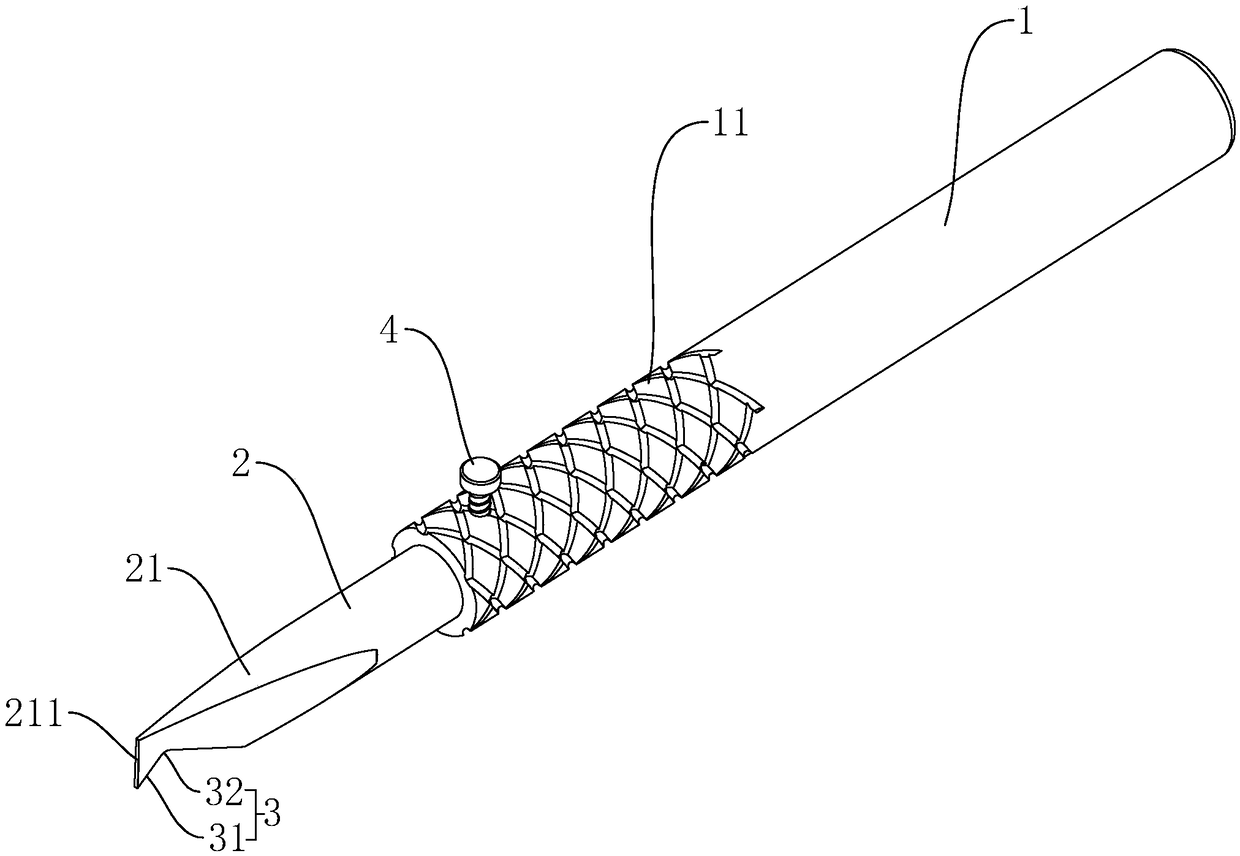

[0035] Such as image 3 Shown, be a kind of manual engraving knife disclosed by the present invention, comprise handle of a knife 1 and cutter 2, one end of cutter 2 is inserted in the cutter 2, and the other end is provided with and is used for die-cutting roller 5 (referring to figure 1 ) on the cutting edge 51 (see figure 2 ) to carry out the blade section 21 of opening, the length of the blade section 21 is 12mm-15mm. The tool 2 and the tool handle 1 are coaxially arranged, and the side wall of the tool handle 1 is threadedly connected with a locking bolt 4, and one end of the locking bolt 4 screwed into the tool handle 1 abuts against the side wall of the tool 2; 1. A knurling section 11 for increasing friction is also provided on the side wall near the end of the tool 2, so as to increase the stability of the worker when holding the tool handle 1 while working.

[0036] Such as image 3 As shown, the end face of the blade section 21 away from the handle 1 is defined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com