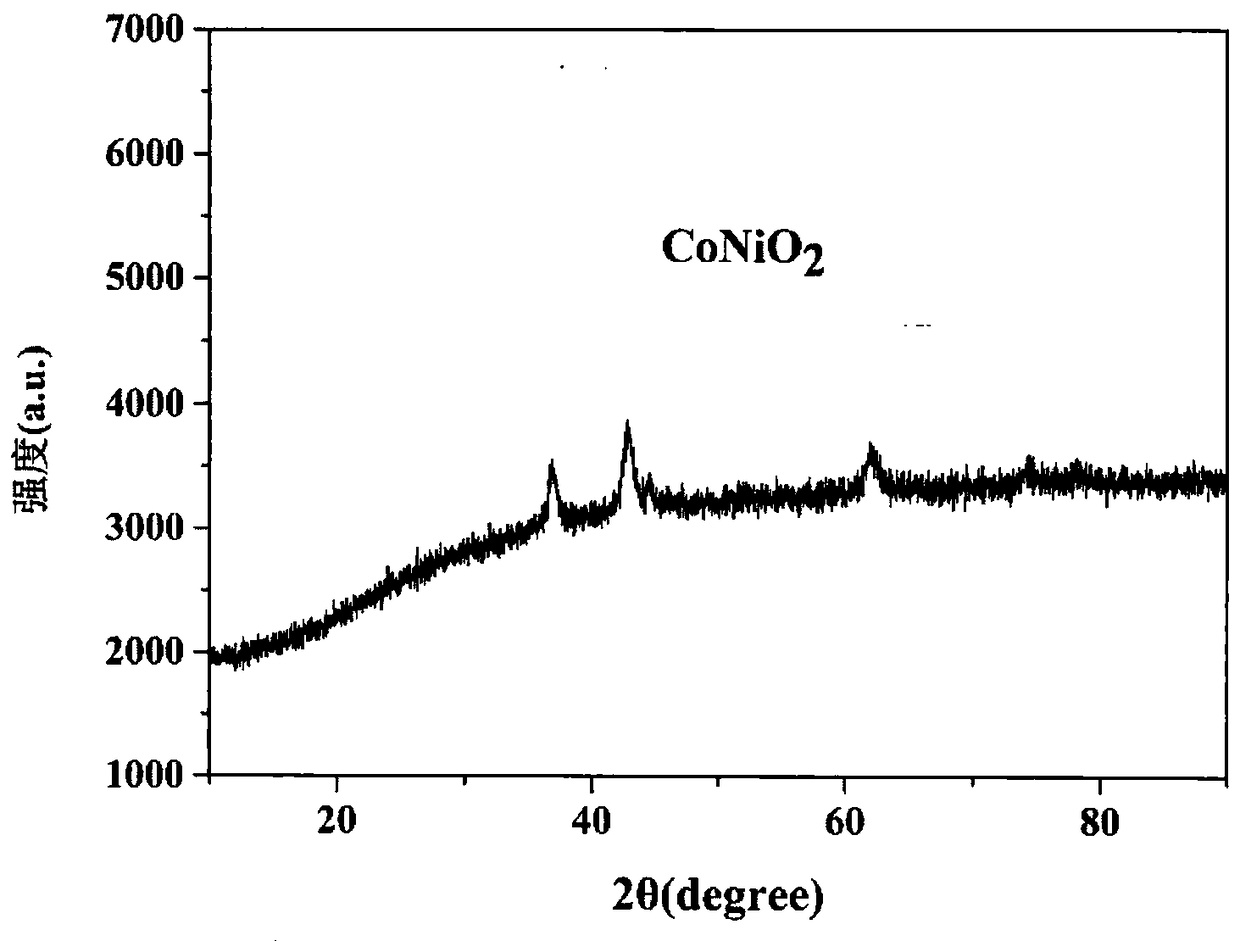

Method of trace detection of copper ion through CoNiO2 nanomaterial modified glassy carbon electrode

A glassy carbon electrode and nanomaterial technology, applied in the field of nanomaterials for electrochemical detection, can solve problems such as energy consumption, excessively long preparation period, uneven distribution of particle size and morphology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Hydrothermal preparation of hydroxides:

[0026] a. Weigh nickel nitrate and cobalt nitrate in a molar ratio of 1:1 and mix them, dissolve them in deionized water, stir evenly, and prepare a 0.1mol / L mixed solution;

[0027] b, then weigh sodium hydroxide according to the molar ratio of sodium hydroxide, nickel nitrate and cobalt nitrate as 1.2:1, and make a solution with a concentration of 0.1mol / L, then add the prepared solution dropwise to the mixture obtained in step a In the solution, stir magnetically at room temperature for 1 hour, then let it stand for precipitation for 12 hours, filter and wash until neutral, and dry at 50°C for 6 hours to obtain a precipitate;

[0028] c. Disperse the precipitate obtained in step b in deionized water containing 0.5wt% polyvinylpyrrolidone, stir it magnetically for 1 hour, put it into a 100mL high-pressure hydrothermal kettle, control the filling ratio at 50%, and the hydrothermal temperature is 100°C. The hydrothermal synthes...

Embodiment 2

[0040] Hydrothermal preparation of hydroxides:

[0041] a. Take nickel nitrate and cobalt nitrate according to the molar ratio of 1:1 and mix them, dissolve them in deionized water, stir evenly, and prepare a 3mol / L mixed solution;

[0042] b, then weigh sodium hydroxide according to the molar ratio of sodium hydroxide, nickel nitrate and cobalt nitrate as 1.2:1, and make a solution with a concentration of 3mol / L, then add the prepared solution dropwise to the mixed solution obtained in step a , stirred magnetically at room temperature for 2 hours, then allowed to settle for 24 hours, filtered and washed until neutral, and dried at 80°C for 10 hours to obtain a precipitate;

[0043] c. Disperse the precipitate obtained in step b in deionized water containing 4wt% polyvinylpyrrolidone, stir it magnetically for 2 hours, put it into a 100mL high-pressure hydrothermal kettle, control the filling ratio at 70%, and the hydrothermal temperature is 140°C. For hydrothermal synthesis u...

Embodiment 3

[0056] Hydrothermal preparation of hydroxides:

[0057] a. Take nickel nitrate and cobalt nitrate as 1:1 by molar ratio and mix them, dissolve them in deionized water, stir evenly, and prepare a 5mol / L mixed solution;

[0058] b, then weigh sodium hydroxide by the molar ratio of sodium hydroxide, nickel nitrate and cobalt nitrate to be 1.2:1, and make a solution with a concentration of 5mol / L, then add the prepared solution dropwise to the mixed solution obtained in step a , stirred magnetically at room temperature for 3 hours, then allowed to settle for 48 hours, filtered and washed until neutral, and dried at 100°C for 12 hours to obtain a precipitate;

[0059] c. Disperse the precipitate obtained in step b in deionized water containing 8wt% polyvinylpyrrolidone, stir it magnetically for 3 hours, put it into a 100mL high-pressure hydrothermal kettle, control the filling ratio at 80%, and the hydrothermal temperature is 200°C. In order to carry out hydrothermal synthesis und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com